13 New Bug Pano Sunroof Leather Automatic Spoiler Limited Vw Guitar 10k Miles on 2040-cars

Ridgeland, Mississippi, United States

Volkswagen Beetle-New for Sale

2004 volkswagen gls(US $6,900.00)

2004 volkswagen gls(US $6,900.00) 2013 beetle turbo w/sunroof(US $23,500.00)

2013 beetle turbo w/sunroof(US $23,500.00) 1999 volkswagen beetle gls 5 speed manual 2-door hatchback(US $8,800.00)

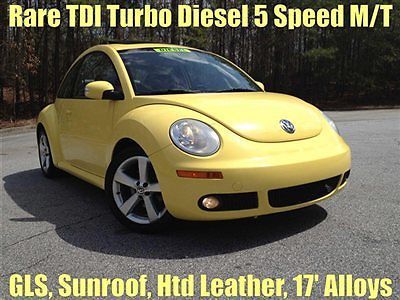

1999 volkswagen beetle gls 5 speed manual 2-door hatchback(US $8,800.00) Rare tdi turbo diesel 5 speed manual gls heated leather sunroof(US $9,981.00)

Rare tdi turbo diesel 5 speed manual gls heated leather sunroof(US $9,981.00) 2.0l turbo low miles white black 6 speed vw 12 bug factory warranty clean carfax

2.0l turbo low miles white black 6 speed vw 12 bug factory warranty clean carfax 2013 vw beetle turbo convertible auto dsg navigation premium fender audio cpo

2013 vw beetle turbo convertible auto dsg navigation premium fender audio cpo

Auto Services in Mississippi

Wathas ★★★★★

Sistrunk`s Sales & Service ★★★★★

S & S Auto Sales ★★★★★

Petal Auto Parts Inc ★★★★★

Natchez Ford Lincoln Mercury ★★★★★

Marion Towing ★★★★★

Auto blog

Horn, Hackenburg, Hatz to be fired as VW diesel scandal deepens

Thu, Sep 24 2015Volkswagen will sack three more high ranking executives, including the head of its US division, as the company's diesel scandal deepens. Reuters reported Thursday morning that the executives are: Michael Horn, who has led VW's US operations since January 1, 2014; Ulrich Hackenberg, who oversaw Audi's research and development; and Wolfgang Hatz, who was in charge of R&D for Porsche. A VW spokesman wouldn't comment in response to an Autoblog email. The moves come in the wake of longtime VW chief executive Martin Winterkorn stepping down on Wednesday. Volkswagen's board said at the time that it expected more personnel changes to follow. Volkswagen's board is scheduled to meet Friday, and Porsche CEO Matthias Muller has reportedly been named as Winterkorn's successor. The German auto giant was plunged into crisis last Friday when the EPA charged that the company manipulated software in its diesel-powered cars to pass US emissions tests. About 482,000 vehicles in the US are affected, and VW estimates 11 million around the world could have the rigged software. The revelations have prompted outcry from governments and regulatory agencies, and in the US, Volkswagen could face a fine of up to $18 billion. The departure of Horn, Hackenberg, and Hatz is a stunning downfall for three of the company's top and most visible executives. Horn had led US operations for less than two years, taking over from Jonathan Browning, who was well-respected but failed to reach VW's ambitious sales targets. Before overseeing Audi R&D, Hackenberg was hailed as a visionary for work in developing VW's modular architectures, which allow the company to save time and money by building many vehicles off the same chassis. Hatz had led Porsche R&D since 2011 and also was in charge of engines and transmission development for all of Volkswagen. Related Video: News Source: ReutersImage Credit: Getty Images Government/Legal Green Hirings/Firings/Layoffs Audi Porsche Volkswagen Emissions Diesel Vehicles vw diesel scandal vw diesel ulrich hackenberg michael horn wolfgang hatz

BMW, Ferrari, VW cars use tungsten mined by terrorists

Thu, 08 Aug 2013Bloomberg Markets is reporting that BMW, Volkswagen and Ferrari have been using tungsten ore sourced from Columbia's FARC rebel terrorists. The extensive story focuses on Columbia's illegal mining trade and calls into question the provenance of the rare ore that is used not only in crankshaft parts production, but is also found in the world's computing and telecommunications industry for use in screens.

The ore is mined by the FARC (Fuerzas Armadas Revolucionarias de Colombia, or Revolutionary Armed Forces of Colombia - People's Army), and exported to Pennsylvania, where it is refined. The refined ore is then sent over to Austria, where a company called Plansee turns it into a finished product. Now, it's important to note that we aren't talking about the world's supply of tungsten here. In 2012, Plansee's American refinery purchased 93.2 metric tons of tungsten, valued at $1.8 million. That's peanuts, with the entire Colombian tungsten mining industry producing just one percent of the world's supplies.

That doesn't make indirectly supporting FARC any more acceptable, though. BMW, VW and Ferrari are all committed to not accepting mineral supplies from the Democratic Republic of Congo, which is also in the grips of a guerrilla insurrection funded, in part, by illegal mining. The same commitment would figure to extend to Colombian mining, but as BMW points out, it's difficult for a multi-national manufacturer to know where every item in its supply chain comes from. A company spokesperson says as much, telling Bloomberg, "These few grams out of the billions of tons of raw materials passing through the BMW supply chain are of no practical relevance."

VW agrees to halt next-gen rally car development to help others stay in WRC

Sat, 22 Jun 2013Volkswagen has petitioned the FIA to hold on to the current specifications for cars in the World Rally Championship, according to Autosport.com. The move is evidently an effort to keep as many competitors in the sport as possible, despite the fact that using the current spec racers may actually hurt Volkswagen's chances at winning. The three factory teams currently competing in the WRC are at the end of a three-year homologation cycle at the end of 2013, and new cars are expected to bow next year. But developing new racers could cost as much as $4.7 million.

That price tag would put M-Sport (which fields Ford racers) out of the WRC game for 2014 and would put Citroën participation in question as well. VW has already begun work on the next iteration of its Polo R WRC, and the hatch has nabbed four wins in six rounds this season. Now it appears that car won't bow until at least 2015. The FIA has officially agreed to freeze homologation of new WRC cars until the end of next season.