We Finance We Ship 1.5l 4 Cyl Fuel Saver 100k Miles 4 Door 2007 on 2040-cars

Peru, Illinois, United States

Toyota Yaris for Sale

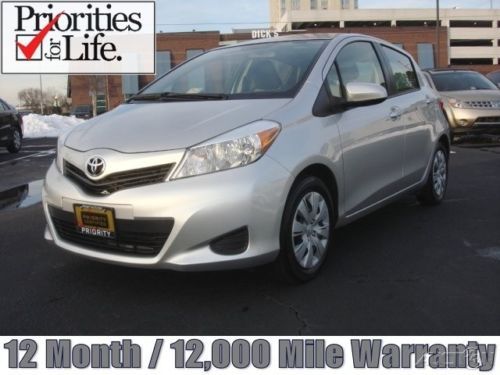

2013 toyota yaris no reserve clean 4cyl hatchback auto trans runs & drives great

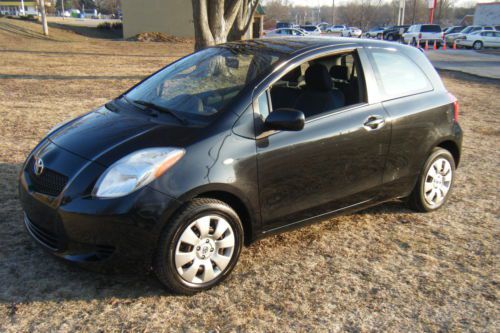

2013 toyota yaris no reserve clean 4cyl hatchback auto trans runs & drives great 2008 toyota yaris 3 door hatchback manual transmission

2008 toyota yaris 3 door hatchback manual transmission 2007 yaris 4 door auto 1.5l vvt-i pw pl pm cd a/c cruise 85k blue(US $7,995.00)

2007 yaris 4 door auto 1.5l vvt-i pw pl pm cd a/c cruise 85k blue(US $7,995.00) Silver clean carfax 1 owner aux usb ipod 12v

Silver clean carfax 1 owner aux usb ipod 12v Clean in & out! runs perfect! a true fuel miser! come see this economical yaris!

Clean in & out! runs perfect! a true fuel miser! come see this economical yaris! 2013 toyota yaris le damaged salvage economical starts only priced to sell l@@k!(US $6,950.00)

2013 toyota yaris le damaged salvage economical starts only priced to sell l@@k!(US $6,950.00)

Auto Services in Illinois

Webb Chevrolet ★★★★★

Wally`s Collision Center ★★★★★

Twin City Upholstery Ltd. ★★★★★

Tuffy Auto Service Centers ★★★★★

Towing St. Louis ★★★★★

Suburban Wheel Cover Co ★★★★★

Auto blog

Tier 1 suppliers call GM the worst OEM to work with

Mon, 12 May 2014Among automakers with a big US presence, General Motors is the worst to work for, according to a new survey from Tier 1 automotive suppliers, conducted by Planning Perspectives, Inc.

The Detroit-based manufacturer, which has been under fire following the ignition switch recall and its accompanying scandal, finished behind six other automakers with big US manufacturing operations. Suppliers had issues with trust and communications, as well as intellectual property protection. GM was also the least likely to allow suppliers to raise their prices in the face of unexpected increases in material cost, all of which contributed to 55 percent of suppliers saying their relationship with GM was "poor to very poor."

GM's cross-town competitors didn't fare much better. Chrysler finished in fifth place, ahead of GM and behind Dearborn-based Ford, which was passed for third place this year by Nissan. Toyota took the top marks, while Honda captured second place.

Automakers donating money, vehicles and supplies to Oklahoma tornado relief effort

Fri, 24 May 2013Judging by the destruction the Oklahoma City area experienced earlier this week, residents are going to need a lot of help in coming months. Fortunately, a number of automakers - including General Motors, Ford, Chrysler, Volkswagen, Honda and Toyota - have stepped up to donate money, supplies and vehicles to aid in the recovery and rebuilding processes.

Here's a quick rundown of which automakers have pitched in and what each contributed so far:

Ford Motor Company has donating $250,000 and a Transit Connect to the American Red Cross, and it will match all other donations made to the Red Cross (up to $250,000) using a special URL tied to the latter's website (link here). Additionally, its local Oklahoma dealers have thrown in an extra $150,000 for the United Way and the automaker will be offering an extra $500 toward the purchase of a new Ford vehicle.

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."