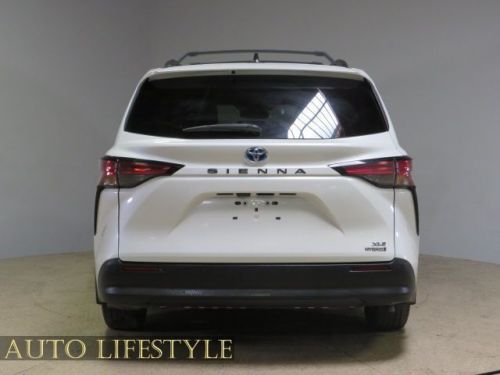

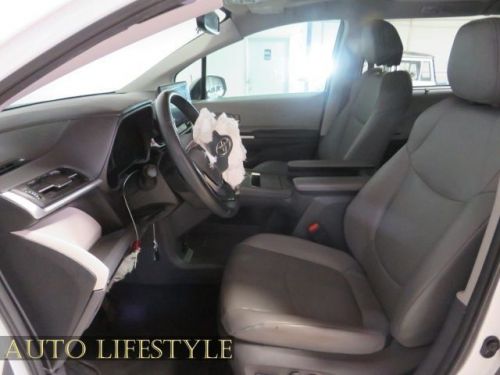

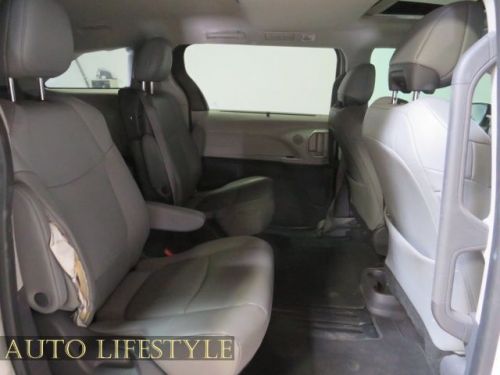

2021 Toyota Sienna Xle 8-passenger on 2040-cars

Gardena, California, United States

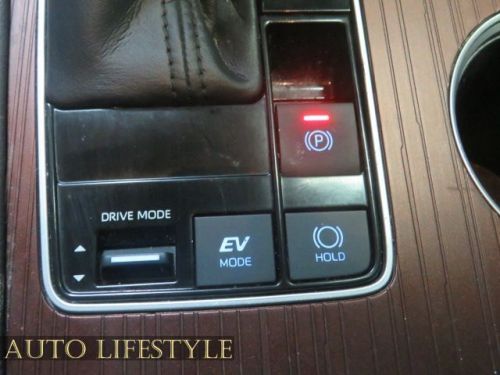

Engine:2.5L Hybrid I4 245hp

Body Type:Mini-Van Passenger

Fuel Type:Gas/Electric Hybrid

For Sale By:Dealer

Year: 2021

VIN (Vehicle Identification Number): 5TDYRKEC4MS025588

Mileage: 57661

Make: Toyota

Model: Sienna

Trim: XLE 8-Passenger

Number of Cylinders: 4

Toyota Sienna for Sale

2008 toyota sienna xle(US $1,000.00)

2008 toyota sienna xle(US $1,000.00) 2020 toyota sienna le mobility handicap van handicap(US $55,900.00)

2020 toyota sienna le mobility handicap van handicap(US $55,900.00) 2022 toyota sienna xle(US $41,888.00)

2022 toyota sienna xle(US $41,888.00) 2018 toyota sienna l(US $22,881.00)

2018 toyota sienna l(US $22,881.00) 2006 toyota sienna le(US $5,995.00)

2006 toyota sienna le(US $5,995.00) 2023 toyota sienna xle(US $30,373.70)

2023 toyota sienna xle(US $30,373.70)

Auto Services in California

Windshield Repair Pro ★★★★★

Willow Springs Co. ★★★★★

Williams Glass ★★★★★

Wild Rose Motors Ltd. ★★★★★

Wheatland Smog & Repair ★★★★★

West Valley Smog ★★★★★

Auto blog

Automakers donating money, vehicles and supplies to Oklahoma tornado relief effort

Fri, 24 May 2013Judging by the destruction the Oklahoma City area experienced earlier this week, residents are going to need a lot of help in coming months. Fortunately, a number of automakers - including General Motors, Ford, Chrysler, Volkswagen, Honda and Toyota - have stepped up to donate money, supplies and vehicles to aid in the recovery and rebuilding processes.

Here's a quick rundown of which automakers have pitched in and what each contributed so far:

Ford Motor Company has donating $250,000 and a Transit Connect to the American Red Cross, and it will match all other donations made to the Red Cross (up to $250,000) using a special URL tied to the latter's website (link here). Additionally, its local Oklahoma dealers have thrown in an extra $150,000 for the United Way and the automaker will be offering an extra $500 toward the purchase of a new Ford vehicle.

Honda Civic losing ground to Toyota Corolla, sales crown threatened

Wed, Dec 17 2014Oh, what a difference a year has made. When the numbers were tallied for 2013, the Honda Civic was riding high by claiming its segment's sales crown in the US despite being challenged by the latest generation of the Toyota Corolla for part of the year. However, with just a month to go in the battle for C-segment supremacy in 2014, it looks like Toyota gets to hoist the trophy this time. Looking at November sales numbers, Honda moved 300,644 Civics through the first 11 months of the year, down 2.1 percent in volume. Furthermore, for the month alone, the company sold 23,060 Civics, a 12.3 percent drop. Meanwhile, on Toyota's side, business has been booming comparatively. Through the first 11 months it sold 309,373 Corollas, a 10.6 percent jump, and for November alone it moved 25,609 examples, a 14.2 percent improvement. With fewer than 10,000 cars between them, it would take quite a December slump for the Corolla to lose this fight. According to The Truth About Cars, the Civic actually started out the 2014 somewhat positively with 5 percent growth over the previous year, though still behind the Corolla's figures. However, the Honda has seen a slide since then with five consecutive months of sales drops. Meanwhile, the Toyota has generally kept showing growth. Being the newer model of the two, the Corolla comes to this fight with an advantage. Honda hasn't let the Civic languish; it gave the model a CVT in 2014 to boost fuel economy. That's nothing like the Toyota's thorough recent rethink, though. According to TTAC, Honda does have reason to crow about the Civic, just not necessarily in the US. The model is on track to be the bestselling vehicle in Canada for the 17th consecutive year and have its best sales since 2008 there.

Oh Buoy! Toyota sinks to Spongebob depths with custom Highlander

Mon, 15 Jul 2013The launch of the 2014 Toyota Highlander is being assisted by Bikini Bottom's number one resident, SpongeBob SquarePants. The new crossover has been wrapped with SpongeBob's square mug all over it as if he's saying "I'm ready. I'm ready. I'm ready. I'm ready," from every direction. Inside is a cabin that Toyota says "captures all of the beloved character's high-octane energy," but might make you question whether this is really the world you want to live in.

Revealed on SpongeBob Day at the San Diego Padres vs. San Francisco Giants baseball game in San Diego, CA on July 13, the Highlander will go from there to seven locations nationwide on a "Happy Driving Tour," ending at the LA Auto Show in November.

You can read all about it in the press release below, as well as ways to fill your life with more SpongeBob than is probably healthy.