2012 Toyota Camry Se Paddle Shift Heated Seats 28k Mi Texas Direct Auto on 2040-cars

Stafford, Texas, United States

Toyota Camry for Sale

Auto Services in Texas

Zeke`s Inspections Plus ★★★★★

Value Import ★★★★★

USA Car Care ★★★★★

USA Auto ★★★★★

Uresti Jesse Camper Sales ★★★★★

Universal Village Auto Inc ★★★★★

Auto blog

Subaru to stop building Camry for Toyota in the US

Fri, 09 May 2014It was back in 2007 that Subaru of Indiana Automotive, under contract from Subaru minority shareholder Toyota, built the first Toyota Camry at its plant in Lafayette, Indiana. Rumblings of the end of that contract work have been around for a while, as Subaru talked of expanding capacity to build more units and add a line for the Impreza, and Toyota talked of moving Camry production to its Georgetown, KY plant. The news was official internally last November when SIA Executive Vice President Tom Easterday told the Louisville Courier-Journal that Camry production would end. Now, Automotive News reports that both automakers have admitted publicly that the end will come in 2016.

SIA currently has a 170,000-unit capacity devoted to the home-brand Legacy and Outback models, while a $400-million expansion increases that to 300,000 units to prepare the facility for Impreza production in two years. Freeing up the 100,000 units of production devoted to the Camry means a 400,000-unit capability, which is far more than Subaru needs at the moment, but the Toyota exit will allow it to expand any way it sees fit. Subaru has said it will absorb the workers on the Camry line and no jobs will be lost, the mayor of Lafayette saying the development could change the timetable for the expansion.

Forza Horizon 3 car list keeps on truckin'

Tue, Aug 9 2016We've covered three weeks of car reveals for Forza Horizon 3, and this time we get a better look at the trucks, SUVs and other off-roaders you'll be able to use to explore Australia. This week's list kicks things off with two of the most legendary off-roaders in the world, the Toyota FJ40 Land Cruiser and the Meyers Manx. They have different purposes; the FJ40 is for tough trail work and the Manx is for some light-hearted beach fun. But no one could deny the cultural importance of either. And both should be a blast in Horizon 3. In addition to this pair of classics, players will have a chance to get behind the wheel of both a race version of the Ford F-150 Raptor and its closest rival, the Ram Runner. And when traditional vehicles start to get boring, why not take out a full-blown Baja racer such as the Penhall Cholla or the Rockstar energy drink version of the little Polaris RZR XP 1000 side-by-side? Forza Horizon 3 is shaping up to have one of the most diverse car lists in a racing game in a long time. There are still cars left to be revealed, so stay tuned for further installments and see this week's full list below. 1957 Chevrolet Bel Air 2002 Ferrari 575M Maranello 1992 Ford Escort RS Cosworth 2013 Ford Focus ST 1973 Ford Escort RS1600 1971 Ford Falcon XY GTHO Phase III 2014 Ford Fiesta ST 2017 Ford F-150 Raptor Race Truck 1954 Jaguar XK120 SE 2014 Jeep Grand Cherokee SRT 2012 Lamborghini Aventador LP700-4 1986 Lancia Delta S4 2009 Lexus IS F 1957 Maserati 300 S 1994 Mazda MX-5 Miata 1967 Mercedes-Benz 280 SL 2009 Mercedes-Benz SL 65 AMG Black Series 1971 Meyers Manx 2012 Mini John Cooper Works GP 1998 Nissan R390 1979 Opel Kadett C GT/E 2011 Penhall The Cholla 1971 Plymouth Cuda 426 Hemi 2015 Polaris RZR XP 1000 EPS Rockstar Edition 2013 Ram Runner 1993 Renault Clio Williams 1990 Subaru SVX 1979 Toyota FJ40 2005 TVR Sagaris 1990 Vauxhall Lotus Carlton Related Video: News Source: Playground Games / MicrosoftImage Credit: Playground Games / Microsoft Auto News Toys/Games Ford RAM Toyota forza exclusive ford f-150 raptor forza horizon forza horizon 3 toyota fj40 meyers manx

Toyota previews next Lexus RX with Tokyo-bound JDM Harrier

Wed, 13 Nov 2013The Lexus RX shares much with the Toyota Highlander, but its more direct counterpart is the Toyota Harrrier. Never heard of it? That's because Toyota only sells it at home in Japan, and now it's revealed a new one. So if the Harrier is essentially a Toyota-badged version of the RX, then what's the big deal, you ask? The big deal is that the new Harrier which leaked in July, set to debut at the Tokyo Motor Show next week and which you see here isn't quite the same as the Lexus, and those differences could (and in most cases likely will) make their way over to the RX as well.

For starters, the styling is different. Granted that the Lexus version will almost certainly get a spindle-shaped grille, but even so, the Harrier's nose seems to protrude further than the RX's and the headlamps are a notably different shape. The greenhouse is also a different shape, coming to a sharper point at the back, and the mirrors are fixed to the A-pillar not to the door panel. The taillamps are revised, the tailgate has a new profile and there's a pseudo-diffuser at the bottom of the rear bumper. Subtle changes, to be sure, but then Toyota and Lexus are known for their evolutionary approach to styling. The interior has apparently undergone some updates as well, with a more dynamically styled dashboard, a more symmetrical center stack and different seats, steering wheel, door panels... the works. The infotainment display screen has also moved further down from its position in the current RX.

Toyota will offer the new Harrier with a 2.0-liter four mated to a CVT and driving either the front wheels or all four, and a hybrid setup with a 2.5-liter married to a 140-hp electric motor. The RX is offered here with a 3.5-liter V6 either on its own or with an electric assist. We wouldn't expect Lexus to go swapping the larger engines for the smaller ones, at least not for the US market. There's plenty more to the Harrier, of course, than the similarities and differences to the Lexus RX, and if you're buying a premium crossover in Japan, you can delve into the full details in the press release below, together with the images in the gallery above.

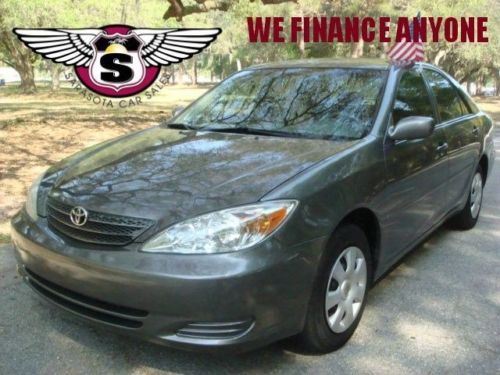

2003 toyota camry xle sedan 4-door 2.4l

2003 toyota camry xle sedan 4-door 2.4l 2000 ce used 2.2l i4 16v automatic sedan

2000 ce used 2.2l i4 16v automatic sedan Toyota camry hybrid xle 2012

Toyota camry hybrid xle 2012 2011 toyota

2011 toyota Le 2.4l cd front wheel drive tires - front all-season tires - rear all-season

Le 2.4l cd front wheel drive tires - front all-season tires - rear all-season 2007 toyota xle

2007 toyota xle