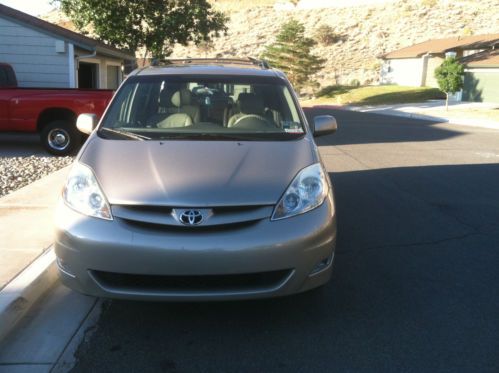

2007 Xle Used 3.5l V6 24v Automatic Fwd Premium on 2040-cars

Orlando, Florida, United States

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Dealer

Year: 2007

Number of Cylinders: 6

Make: Toyota

Model: Sienna

Warranty: No

Drive Type: FWD

Mileage: 117,792

Sub Model: XLE

Exterior Color: Blue

Number of Doors: 4 Doors

Interior Color: Gray

Toyota Sienna for Sale

2006 toyota sienna xle awd passenger van 5-door 3.3l. fully loaded!!!!(US $14,999.00)

2006 toyota sienna xle awd passenger van 5-door 3.3l. fully loaded!!!!(US $14,999.00) 2001 fully loaded toyota sienna xle fwd 7 passenger for sale(US $4,499.00)

2001 fully loaded toyota sienna xle fwd 7 passenger for sale(US $4,499.00) Le 3.5l cd front wheel drive power steering 4-wheel disc brakes aluminum wheels

Le 3.5l cd front wheel drive power steering 4-wheel disc brakes aluminum wheels 7-pass van v 3.5l leather sunroof (10) cup holders (3) 12v pwr outlets(US $31,988.00)

7-pass van v 3.5l leather sunroof (10) cup holders (3) 12v pwr outlets(US $31,988.00) 2005 toyota sienna le !!one owner tennessee van!! ready to go anywhere today(US $6,555.00)

2005 toyota sienna le !!one owner tennessee van!! ready to go anywhere today(US $6,555.00) 2003 toyota sienna le 1 owner clean car fax florida owned exceptionally clean.

2003 toyota sienna le 1 owner clean car fax florida owned exceptionally clean.

Auto Services in Florida

Yesterday`s Speed & Custom ★★★★★

Wills Starter Svc ★★★★★

WestPalmTires.com ★★★★★

West Coast Wheel Alignment ★★★★★

Wagen Werks ★★★★★

Villafane Auto Body ★★★★★

Auto blog

Sales incentive growth clustered around brands with few CUVs, trucks

Wed, 24 Sep 2014While it's arguably been around the longest, the dominance of the four-door sedan has been under threat for many years. As a further sign of the hurtin' that SUVs and crossovers have put on today's four-doors, a new report from Automotive News points to the increasing use of incentives by brands reliant on cars and light on CUVs and pickups.

Honda, Toyota, Volkswagen and Kia have all been stung by double-digit increases in their incentives-to-transaction price ratio, according to AN, which cites data from TrueCar. Honda's ratio is up 14 percent, while Toyota, VW and Kia are up 18, 15 and 19 percent, respectively.

"Most of the incentive growth we have seen is in product segments with low demand - midsized or large sedans," TrueCar CEO John Krafcik told AN. "As this trend goes on, the brands with three-sedan strategies are going to be in worse shape on incentive spending than the crossover brands."

Toyota nears $40B cash reserve as calls grow for new investment, payouts

Wed, 05 Feb 2014With the April 15 tax deadline just a few months away, our US readers will be faced with a decision should they get a refund: save or spend? It seems this issue is one many of us face whenever there's a windfall, trying to decide whether we should set the money aside in an account of some sort or use it as a down payment on a new car or a trip to the Apple store. Unsurprisingly, major corporations face a similar, albeit more complex, issue.

Take Toyota, for example. With President Akio Toyoda at the helm, the Japanese manufacturer has gracefully weathered recalls and natural disasters, all while turning beaucoup profits. Last quarter, profits quintupled to 434.4-billion yen ($4.3-billion USD), according to Bloomberg. Toyota also upped its forecast for the end of fiscal year 2013 (which ends on March 31 for Japan), to a record 1.9-trillion yen (about $18.8 billion). Now, the Japanese brand is reportedly sitting on a cash pile of nearly $40 billion, leaving Toyoda-san in an envious predicament - what should the company do with all that money?

Some think Toyota should be doing something, anything with that big stack of cash.

Toyota fears supplier pressure in Australia with GM pull out

Wed, 11 Dec 2013With Ford and General Motors both announcing an end to production in Australia, the country's auto industry is in a bad way. With the exit of two big players, there's increased concern that a third Australian manufacturer, Toyota, will be forced out, as well.

"We are saddened to learn of GM Holden's decision. This will place unprecedented pressure on the local supplier network and our ability to build cars in Australia," Toyota Australia said in a statement. The GM closure of Holden production will be the direct end to 2,900 jobs, but will also force a dramatic reduction in the size of the country's supplier network, as there will simply be fewer cars to build.

In the same statement, Toyota Australia said it would work with suppliers and local government to figure out whether continuing production Down Under was even feasible. According to Automotive News, a representative for the Australian Manufacturing Workers' Union told reporters it was "highly likely" that Toyota would also close up shop within the next few years.

2040Cars.com © 2012-2025. All Rights Reserved.

Designated trademarks and brands are the property of their respective owners.

Use of this Web site constitutes acceptance of the 2040Cars User Agreement and Privacy Policy.

0.154 s, 7841 u