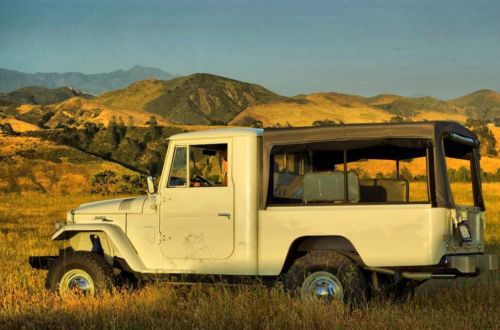

1974 Toyota Land Cruiser Fj40: Very Clean Excellent Mechanical on 2040-cars

Redwood City, California, United States

Toyota Land Cruiser for Sale

1966 toyota land cruiser 3.9l original running gear 1965 1964 1963 1962 1961

1966 toyota land cruiser 3.9l original running gear 1965 1964 1963 1962 1961 No reserve 1-owner 4x4 awd lexus lx450 lx470 tacoma 4runner sr5 fzj80 94 96 97

No reserve 1-owner 4x4 awd lexus lx450 lx470 tacoma 4runner sr5 fzj80 94 96 97 1976 fj40 land cruiser v8 conversion ac ps frame off restorationbj fj cj icon fj

1976 fj40 land cruiser v8 conversion ac ps frame off restorationbj fj cj icon fj 1964 fj45 toyota land crusier short bed pickup w/ pro sbc v8 conversion icon tlc(US $100,000.00)

1964 fj45 toyota land crusier short bed pickup w/ pro sbc v8 conversion icon tlc(US $100,000.00) 1985 toyota land cruiser lowest milage in the world

1985 toyota land cruiser lowest milage in the world 2009 toyota land cruiser black (pristine!)

2009 toyota land cruiser black (pristine!)

Auto Services in California

Yuba City Toyota Lincoln-Mercury ★★★★★

World Auto Body Inc ★★★★★

Wilson Way Glass ★★★★★

Willie`s Tires & Alignment ★★★★★

Wholesale Import Parts ★★★★★

Wheel Works ★★★★★

Auto blog

Details about next-gen Toyota Prius emerge

Tue, 28 Jan 2014The Toyota Prius is undeniably the king of the hybrid market in the United States, with a 39.4 percent market share in 2013. With the next-generation Prius likely to go on sale in 2015, Toyota is trying to build an even more efficient hybrid to keep its control of the market.

Keeping cost down will be one of the major concerns of the new Prius. The next generation will ride on the new, modular Toyota New Global Architecture platform. The lighter underpinnings will improve efficiency and will reduce production costs by allowing for more shared components among vehicles. Toyota will not reveal how many vehicles will use the new platform. But even with the cheaper platform, price will remain a concern. Toyota is still deciding whether all versions of the next Prius will use lithium-ion batteries or whether some models will stick with the heavier nickel-metal hydride batteries to keep cost down.

Of course, the reason most people buy the Prius is because of its great fuel efficiency. Toyota will aim for at least an 8 percent improvement in fuel economy in the next Prius, which would increase it to 58 miles per gallon city and 52 mpg highway.

Scion was Toyota's lost generation

Sat, Feb 6 2016Toyota's top North American leader was succinct in explaining the reasons for killing Scion. "It's the right decision at the right time," Jim Lentz said. It's hard to disagree. In a strong market that saw 17.5 million sales last year, Scion volume dipped three percent. Its product lineup has withered for years, which is always a telltale sign a brand doesn't have the full support of its owner. Though enthusiasts love the FR-S sports car, it's the fruit of a joint project with Subaru that also produced the BRZ. Scion's coolest car has a twin sold by one of its rivals. After the FR-S launched in 2012, Scion got nothing – squat – in the way of new products until the iA and iM arrived late last year, IHS senior analyst Stephanie Brinley noted. "[Scion] was not successful in building a visual brand identity or product personality," she said. Lentz, Scion's first vice president and now CEO of Toyota's North American division, admitted the market has changed. "Younger customers have a different mindset," he said. In the early oughts, a brand that catered to a youthful demographic made some sense, and this is one front where Toyota can declare victory. Seventy percent of Scion's buyers were new to Toyota, and the average age was 36 years old. The problem is, not enough of them buy Scions anymore. Scion hit a highwater sales mark of 173,034 vehicles in 2006 and hasn't come close to reaching that since. The recession hurt Scion, too. It bottomed out in 2010 with just 45,678 sales, a time when the rest of the industry was beginning to recover. There was a brief uptick (73,507) in 2012, but Scion failed to capitalize on that momentum and sales fell for three more years. Toyota is calling Scion's pending death a "transition" back to the main company. Sure, most of the cars will be rebadged Toyotas, like the FR-S, iA, and iM. The C-HR, an attractive future crossover that would have given Scion a boost, will go into production as a Toyota. But make no mistake: This is a failure. Toyota is closing a brand in the same way General Motors scrapped Oldsmobile, Ford shuttered Mercury, and Chrysler dropped Plymouth. Those brands languished for years. Toyota moved quicker to put the fork in Scion, which prevented it from becoming a long-term drain on the parent company. Lentz was dead on. It's the right time. News & Analysis News: Sergio Marchionne is against a Ferrari SUV Analysis: His exact words were, "you have to shoot me first," Bloomberg reported.

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.