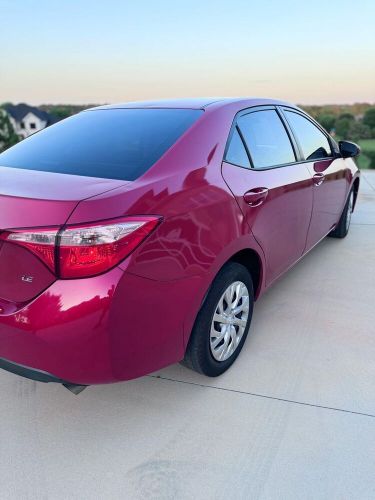

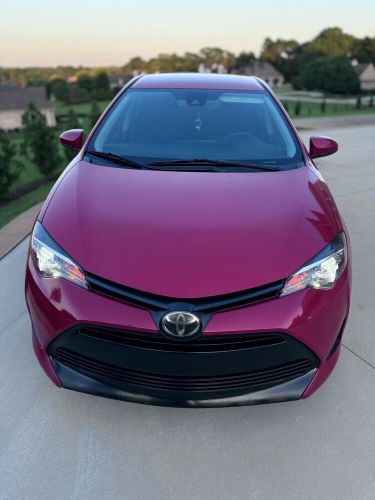

2019 Toyota Corolla Le on 2040-cars

Anderson, South Carolina, United States

Transmission:Automatic

Fuel Type:Gasoline

For Sale By:Dealer

Vehicle Title:Clean

Year: 2019

VIN (Vehicle Identification Number): 5YFBURHE9KP861266

Mileage: 90800

Interior Color: Black

Number of Seats: 5

Trim: LE

Make: Toyota

Drive Type: FWD

Drive Side: Left-Hand Drive

Engine Size: 1.8 L

Model: Corolla

Exterior Color: Red

Number of Doors: 4

Features: Cloth seats, Cruise Control, Electric Mirrors, backup camera

Toyota Corolla for Sale

2020 toyota corolla le(US $12,950.00)

2020 toyota corolla le(US $12,950.00) 2017 toyota corolla le(US $6,500.00)

2017 toyota corolla le(US $6,500.00) 2022 toyota corolla se(US $21,391.00)

2022 toyota corolla se(US $21,391.00) 2024 toyota corolla le(US $22,393.00)

2024 toyota corolla le(US $22,393.00) Insulator exhaust manifold heat , toyota corolla 2004-2008(C $180.00)

Insulator exhaust manifold heat , toyota corolla 2004-2008(C $180.00) Toyota corolla im 2017, 178000 km, winter+ summer tires...(C $17,800.00)

Toyota corolla im 2017, 178000 km, winter+ summer tires...(C $17,800.00)

Auto Services in South Carolina

West Specialty Products Used Cars ★★★★★

Tuffy Auto Service Centers ★★★★★

Star Automotive ★★★★★

Stack`s Wholesale Auto Parts ★★★★★

Scott`s Automotive ★★★★★

Reid`s Towing ★★★★★

Auto blog

Toyota, Honda, Nissan and more collaborating to increase fuel efficiency

Sun, 25 May 2014Toyota, Honda, Mazda, Nissan, Subaru, Mitsubishi, Suzuki and Daihatsu have announced an alliance that will see a push to improve fuel economy from both gas-powered and diesel-powered engines by as much as 30 percent before the end of the decade.

The newly assembled Research Association of Automotive Internal Combustion Engines put the roughly $20-million project together, with the Japanese government committing to half the cost while the eight manufacturers will chip in the rest.

According to Automotive News, the automakers will team up and share basic research on internal-combustion engines in a bid to cut costs. Eventually, the results of the research will find its way into a production vehicle, although it's unclear just when we'll see the fruits of this partnership on the road.

Dutch Toyota dealer has plans for old Prius batteries as solar backup

Thu, May 1 2014A Toyota dealer in the Netherlands is looking to the sky for power. The Louwman Hague Toyota dealership has put almost 1,000 solar panels on the roof, and there might be some Prius hybrid batteries involved. Our Dutch isn't as good as it could be and our questions to Toyota in the US haven't turned up any definitive answers, but there is some mention that these solar panels are will someday be feeding power into a bank of Toyota hybrid batteries. The 1,000 panels make up 1,600 square meters, about the size of 4.5 IMAX movie screens, and is the largest in the area. They generate around a quarter of a megawatt of energy [as our readers point out, this is what the translation says, but it doesn't make sense, so we think it might mean a quarter MW of power a day], which is enough to power 80 homes. The excess electricity will go into the battery packs that have (possibly) already been used in a Prius or another of the company's hybrid. There are many examples of automotive batteries being tested as stationary back-up power sources, and maybe this Dutch solution can be used as a guide when Toyota sets up its new US headquarters in sunny Texas.

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."