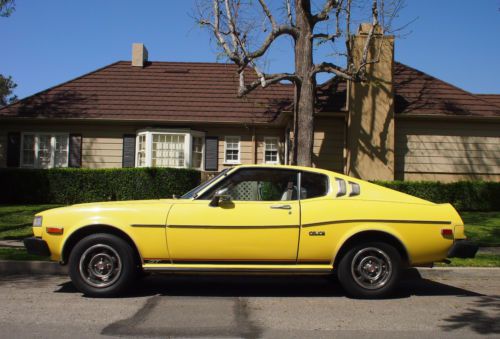

1975 Toyota Celica St Hardtop 2-door 2.2l on 2040-cars

Carmichael, California, United States

|

Toyota Celica for Sale

1991 toyota celica gt convertible 2-door 2.2l(US $7,200.00)

1991 toyota celica gt convertible 2-door 2.2l(US $7,200.00) 2003 toyota celica gt hatchback 2-door 1.8l(US $4,900.00)

2003 toyota celica gt hatchback 2-door 1.8l(US $4,900.00) 1992 toyota celica gt convertible 2-door 2.2l

1992 toyota celica gt convertible 2-door 2.2l 1994 toyota celica gt hatchback 2-door 2.2l

1994 toyota celica gt hatchback 2-door 2.2l 1977 toyota celica gt liftback - one owner, low reserve! -ta28, ra29

1977 toyota celica gt liftback - one owner, low reserve! -ta28, ra29 2004 toyota celica gt hatchback 2-door 1.8l

2004 toyota celica gt hatchback 2-door 1.8l

Auto Services in California

Yoshi Car Specialist Inc ★★★★★

WReX Performance - Subaru Service & Repair ★★★★★

Windshield Pros ★★★★★

Western Collision Works ★★★★★

West Coast Tint and Screens ★★★★★

West Coast Auto Glass ★★★★★

Auto blog

Jim Lentz exposes more details behind Toyota's move to Texas

Fri, 02 May 2014Toyota's North American CEO Jim Lentz has already given us a rough idea of what prompted the company's surprise move to the Dallas suburb of Plano, TX from its longstanding headquarters in Torrance, CA. A new story from The Los Angeles Times, though, delivers even more detail from Lentz on the reasoning for the move, what other cities were considered and why the company's current host city wasn't even in the running.

Of course, one of the more popular reasons being bandied about includes the $40 million Texas was set to give the company for the move, as well as the state's generous tax rates. According to Lentz, though, the reason Toyota chose Plano over a group of finalists made up of Atlanta, Charlotte and Denver, was far simpler than that - it was about consolidating its marketing, sales, engineering and production teams in a region that's closer to the company's seat of manufacturing in the south.

"It doesn't make sense to have oversight of manufacturing 2,000 miles away from where the cars were made," Lentz told The Times. "Geography is the reason not to have our headquarters in California."

How Toyota's Le Mans racer may make its next Prius even better

Fri, Jun 20 2014The supercapacitor technology in the Toyota TS040 "offers great possibility for production car use." – Amanda Rice, Toyota Pop-culture junkies familiar with 1980s touchstone movies will hear the word "capacitor" and think Back to the Future. But the concept of supercapacitors being used in upcoming production models is being pushed by Toyota, not DeLorean. And because of that push, the future might look a little brighter for the Prius. The Japanese automaker will likely apply electric-motor technology used in Toyota's 24 Hours of Le Mans entry – the TS040 – in future versions of the world's best-selling hybrid, Australian publication Drive.com.au says, citing an interview with Toyota Motor Sports' Yoshiaki Kinoshita. Specifically, the racecar uses supercapacitors because they're effective at storing energy created when the vehicle is under braking, only to quickly redistribute it on demand for rapid acceleration. Kinoshita said Toyota may apply this technology to the Prius within the next five years. While declining to comment on specifics, Toyota spokeswoman Amanda Rice tells AutoblogGreen that the Le Mans vehicle "represents an advanced vehicle laboratory for hybrid vehicle and component development. The supercapacitor technology used in this vehicle with its fast charge and discharge capability offers great possibility for production car use." In her email, Rice added that the next-generation Prius will have smaller electric motors with greater power density and thermal efficiency, so let's add that to what we know or think we know about the fourth-generation model. Toyota entered two vehicles in this year's Le Mans race, and one of them had secured the pole-position and was leading much of the race before calling it quits 15 hours in because of electrical issues. Audi ended up winning the race, marking its 13th victory in the history of the French endurance contest.

Honda, Subaru airlifting parts to bypass port labor diputes

Fri, Feb 6 2015It should be abundantly obvious that a vital element in building cars is actually having the components on hand to assemble them. A labor dispute on the West Coast between the International Longshore and Warehouse Union and management is not making that quite so easy for some Japanese automakers. Work slowdowns at the ports have pushed Honda and Subaru parent Fuji Heavy Industries into flying some parts into the country. The two automakers began shipping by airplane late last month to avoid production delays, according to Bloomberg, but it has been an expensive solution. Subaru's chief financial officer said the decision cost around $60 million more per month than sending components by cargo ship. They aren't the only companies dealing with the problem, either. Toyota reportedly stopped overtime assembly at some of its factories here because of the delays in getting parts, according to Bloomberg. The dockworkers have been negotiating on a new contract since May 2014, and the current offer on the table to them has offered a 3 percent raise, according to Bloomberg. Although, the union is reportedly considering another slowdown at 29 ports along the West Coast in the coming days. News Source: BloombergImage Credit: Nick Ut / AP Photo Auto News UAW/Unions Honda Subaru Toyota shipping port labor dispute