2014 Toyota Avalon Hybrid Xle Touring on 2040-cars

3232 Harper Rd., Indianapolis, Indiana, United States

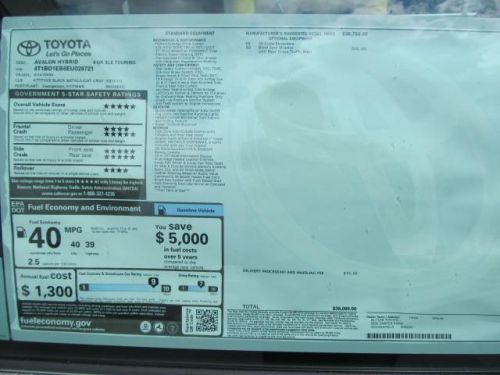

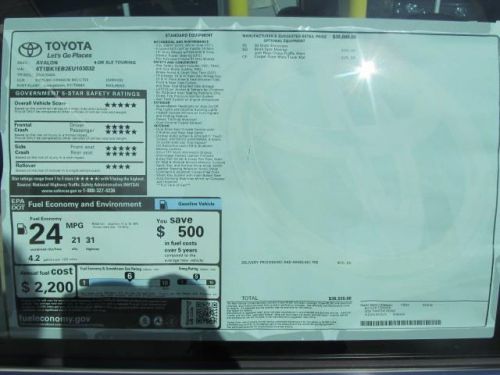

Engine:2.5L I4 16V MPFI DOHC Hybrid

Transmission:Automatic CVT

VIN (Vehicle Identification Number): 4T1BD1EB8EU028721

Stock Num: 28494

Make: Toyota

Model: Avalon Hybrid XLE Touring

Year: 2014

Exterior Color: Black

Interior Color: Light Gray

Options: Drive Type: FWD

Number of Doors: 4 Doors

Butler Toyota Scion is Indiana's largest Toyota Scion dealer. We have been doing business with integrity since 1966. Be sure to visit WWW.BUTLER-TOYOTA.COM for exclusive Butler website specials.

Toyota Avalon for Sale

2014 toyota avalon xle touring(US $32,995.00)

2014 toyota avalon xle touring(US $32,995.00) 2014 toyota avalon hybrid xle touring(US $38,060.00)

2014 toyota avalon hybrid xle touring(US $38,060.00) 2006 toyota avalon xls(US $16,900.00)

2006 toyota avalon xls(US $16,900.00) 1999 toyota avalon xls(US $7,490.00)

1999 toyota avalon xls(US $7,490.00) 2014 toyota avalon limited(US $40,910.00)

2014 toyota avalon limited(US $40,910.00) 2014 toyota avalon xle touring(US $36,785.00)

2014 toyota avalon xle touring(US $36,785.00)

Auto Services in Indiana

Widco Transmissions ★★★★★

Townsend Transmission ★★★★★

Tom`s Midwest Muffler & Brake ★★★★★

Superior Auto ★★★★★

Such`s Auto Care ★★★★★

Shepherdsville Discount Auto Supply ★★★★★

Auto blog

2015 Toyota Prius C is still colorful, still gets 53 mpg

Wed, 19 Nov 2014Few vehicles can match the affordable fuel economy of the $19,000, 53-mile-per-gallon Toyota Prius C, and that fact isn't likely to change for 2015, as the Japanese company has issued a moderate refresh of its sub-compact hybrid.

As mid-cycle refreshes go, this is a pretty standard affair, with a larger grille and tweaked LED headlights at the front of the Prius C, and more expressive taillights at the back. Toyota made some minor changes in the cabin, updating materials throughout, but not fiddling too much with the overall level of equipment.

Aside from those modest changes, this is the same fuel-efficient five-door, retaining its 1.5-liter, 73-horsepower, 82-pound-foot four-cylinder, while an electric motor tosses in an extra 26 ponies, for a total system output of 99 horsepower. Along with the 53-mpg highway rating, the C will return 46 mpg in the city.

Toyota sells six of 10 of hybrids in California

Wed, 31 Jul 2013In an apparent shot back at Ford's increasing market share of electrified vehicles and claim that it accepts more Prius trade-ins for its own hybrids than any other car, Toyota has flexed a muscle and played the numbers game to put the Blue Oval in its place.

Leaning on its hybrid market dominance in California, the Japanese automaker stated that six out of 10 hybrids sold in the Golden State are Toyota models. And it keeps coming: Year-to-date through May 2013, Toyota sold five times more hybrids than Ford. One of every two hybrids in California is a Prius model. In addition, Toyota notes that it has sold 1.5 million Prius vehicles in the US, 90-percent of which are still on the road today.

Want more? We'll let Bill Fay, Toyota's group vice president and general manager of sales lay the smack down:

Ford F-150, Chevy Silverado, Toyota Tundra flunk IIHS headlight test

Tue, Oct 25 2016The Insurance Institute for Highway Safety put pickup truck headlights to the test and found that the majority of them were equipped with subpar units. The 2017 Honda Ridgeline was the only truck to earn a rating of "good." The large pickup truck test was comprised of the: 2016 to 2017 GMC Sierra, 2017 Nissan Titan, 2016 Ram 1500, 2016 to 2017 Chevrolet Silverado, 2016 to 2017 Ford F-150, and 2016 to 2017 Toyota Tundra. The Sierra's headlights earned a rating of "acceptable," the headlights found on the Titan and Ram 1500 were found to be "marginal," and the ones on the Silverado, F-150, and Tundra were rated as "poor." IIHS claims the F-150 was the most disappointing out of the large pickup trucks as both its halogen and optional LED headlights failed to provide adequate visibility during testing. The Ridgeline (which earned a "good rating"), is usually considered a midsize or small truck, though IIHS included it in the field of large pickups. The headlights on the 2016 Chevrolet Colorado, 2016 GMC Canyon, 2016 Nissan Frontier, and 2016 to 2017 Toyota Tacoma, which made up the small pickup truck group, all earned a rating of "poor." The IIHS claimed the Colorado had the worst headlights of any truck that was tested, as the base vehicle's units were only able to illuminate up to 123 feet in front of the car. The Ridgeline's headlights, for reference, were able to illuminate up to 358 feet in front of the vehicle. To conduct its test, the IIHS utilizes a special tool to measure how far light is projected out of the headlights in different driving situations. The trucks' headlights were tested in a straight line and in corners, while vehicles with high-beam assist were given extra praise. The headlights on the pickup trucks also mimic the testing that was done on small SUVs and cars earlier this year. Next year, automakers will need to fit their vehicles with headlights that earn a rating of either good or acceptable to earn the IIHS Top Safety Pick+. Related Video: