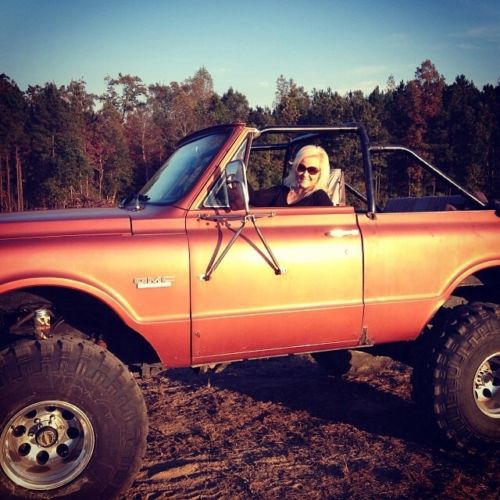

Offroad Buggy Rock Crawler Lifted 4x4 Blazer Exo Cage 37in Tires D44 D60 Jeep on 2040-cars

Austin, Texas, United States

|

Fully tube cage exo skeleton Rock-crawler 12 inch lift 37 inch tires Air lockers front racing seats with four-pointseat belts. The crawler was built from the ground up by 4 Wheel Drive factory it has every top-of-the-line part installed. The Cage alone cost $4000 to make. Yukon Air-locker's and gears front and rear with 5.13 year ratio. 37 inch pit bull rocker tires, has front racing seats and rear bench seat The front seats are equipped with four point seat belts. D 60s front and rear with chrome moly axles. The transfer case has been built and converted to a manual shift. The transmission has also been Built and geared down for torque.The list goes on and on i'm currently waiting on a parts list for everything and all their prices from the Guy who built it at four-wheel-drive factory. The crawler cost more than 25K to build. The cage cost 5K, the axles cost at least 4K, at least $3000 in the lift kit alone .Not to mention all seats belts,tires,wheels,lights, plus the hours upon hours of labor and all the stuff I'm forgetting. If you added up all the costs of all the parts and labor it would be way over 25K to Build the whole thing. The only thing you would really need for this car would be a compressor for onboard air and may be one tire. Only thing that you could do to make this truck any better would be to put bigger tires on it and Hydro steering. However this thing is ready to run ready to get crazy in the woods and has the torque and the equipment to do it. This thing will go up a wall it's an amazing machine that you're getting for Less then half the cost it would be to build one. This thing really is a beast, I just have other projects that I'd like to have the money for the only thing I would be interested in is a Dodge Cummins diesel truck four-wheel-drive no Dully. I'm sure I'm forgetting something with all of the other things it has on it I will also be adding things as I remember them and when I receive the list of parts otherwise message me if you have any questions preferably here on eBay. I'm listing the buy it now price it 9500 dollars but if you have an offer even if it's something you think is low balling shoot me a pm I will look at any offer. We can work something probably some how especially if you have some cash and something that I might be interested that has a motor. The only thing still Jimmy about this entire build is the actual frame engine and parts of the transmission. |

GMC Jimmy for Sale

Auto Services in Texas

Youniversal Auto Care & Tire Center ★★★★★

Xtreme Window Tinting & Alarms ★★★★★

Vision Auto`s ★★★★★

Velocity Auto Care LLC ★★★★★

US Auto House ★★★★★

Unique Creations Paint & Body Shop Clinic ★★★★★

Auto blog

Pony cars, trucks and Italian SUVs | Autoblog Podcast #552

Fri, Aug 31 2018On this week's Autoblog Podcast, Editor-in-Chief Greg Migliore is joined by Senior Editor Alex Kierstein and Associate Editor Reese Counts. We discuss the updated 2019 Chevy Camaro Turbo 1LE variant, the new 2019 GMC Sierra Denali, and the Ferrari-powered Maserati Levante GTS. We also debate whether Volkswagen should build the Atlas-based Tanoak pickup truck and what a delay means for the next-gen Ford Mustang. Finally, we answer a reader question about the state of Lexus.Autoblog Podcast #552 Get The Podcast iTunes – Subscribe to the Autoblog Podcast in iTunes RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Rundown 2019 Chevy Camaro Turbo 1LE 2019 GMC Sierra 2019 Maserati Levante GTS Should Volkswagen build the Tanoak? Next-gen Ford Mustang delayed The past, present and future of Lexus Feedback Email – Podcast@Autoblog.com Review the show on iTunes Related Video: Podcasts Chevrolet Ford GM GMC Lexus Maserati RAM Truck Coupe SUV Luxury Performance

GM claims it's first to sell million 30+ mpg vehicles

Fri, 04 Jan 2013As we continue to put together all the data for the year-end edition of By The Numbers, General Motors has announced that it sold more than a million vehicles in the US last year that achieved at least 30 miles per gallon on the highway. More impressively, GM managed this feat using multiple strategies including small vehicle size, turbocharged engines and hybrid or plug-in technologies across four brands (Buick, Cadillac, Chevrolet and GMC) accounting for 13 separate models. This number will grow even more in 2013 thanks to cars like the all-electric Spark, the diesel Cruze, the range-extended Cadillac ELR and the Buick Encore compact CUV.

GM's small car sales were up 39 percent last year helping to attain this million-sales mark for 30-mpg models, and almost 40 percent of all GM sales consisted of cars with fuel-efficient I4 engines. In regards to more advanced means of improving fuel economy, GM says that it plans on having 500,000 vehicles with "some form of electrification" on the road by 2017.

Scroll down for the full list of GM's million 30+ mpg cars as well as an informative press release.

Next-gen Chevy Silverado and GMC Sierra may use carbon fiber

Thu, Dec 7 2017It's been generally accepted that the next generation of full-size GM trucks will use some sort of strong, lightweight material for the beds while retaining steel for the cab. While aluminum seems like the most obvious choice, according to Automotive News, the Chevy Silverado and GMC Sierra will incorporate both aluminum and carbon fiber in their beds. The publication cites sources from within GM, though it seems the introduction of this comparatively exotic material mix is still a few years off. While carbon fiber is both stronger and lighter than steel and aluminum, it takes significantly more time and money to produce, essentially relegating the material to small-volume cars. The main benefit for trucks is the resulting reduction in weight to improve fuel economy without sacrificing the tough, rugged capabilities truck buyers expect. The Ford F-150 made the switch to aluminum for the 2015 model year and it's proved highly successful. It seemed like it was only a matter of time before the competition followed suit. Automotive News says that the next-gen trucks will launch with aluminum beds and that it will take a couple of years before we'll see any carbon fiber incorporated into the design. Even then, only look for the composite material on higher-trim models, with a trickle down to lower-spec trucks possible further in the future. In 2011, GM announced it was working with Japan-based Teijin Limited on a carbon fiber reinforced thermoplastic. There's a good chance that material's introduction will be on trucks. Related Video: News Source: Automotive News Plants/Manufacturing Rumormill Chevrolet GM GMC Truck

1979 gmc jimmy **66,548 original miles**

1979 gmc jimmy **66,548 original miles** 2000 gmc jimmy sls sport utility 2-door 4.3l awd 4wd

2000 gmc jimmy sls sport utility 2-door 4.3l awd 4wd Gmc jimmy slt 4wd '99 obo

Gmc jimmy slt 4wd '99 obo 1970 gmc jimmy blazer convertible lifted

1970 gmc jimmy blazer convertible lifted 1987 gmc jimmy sierra classic sport utility 2-door 5.0l

1987 gmc jimmy sierra classic sport utility 2-door 5.0l 1986 full size gmc jimmy blazer 4x4 blue

1986 full size gmc jimmy blazer 4x4 blue