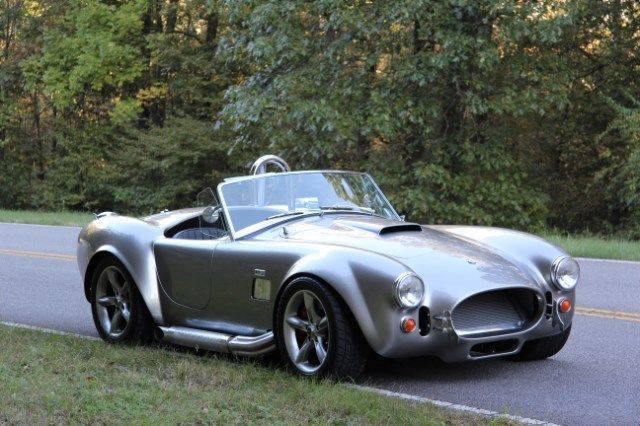

Ford Street Rod on 2040-cars

Tucson, Arizona, United States

If you have any questions regarding this beautiful car please do not

hesitate to email at:annacarey75@gmail.com

Ford Other Pickups for Sale

Ford hot rod-all steel(US $22,000.00)

Ford hot rod-all steel(US $22,000.00) Ford hot rod-all steel(US $21,000.00)

Ford hot rod-all steel(US $21,000.00) 1965 shelby cobra(US $16,500.00)

1965 shelby cobra(US $16,500.00) 1966 replicakit makes shelby cobra(US $11,000.00)

1966 replicakit makes shelby cobra(US $11,000.00) 1946 ford other(US $17,000.00)

1946 ford other(US $17,000.00) 1965 shelby shelby(US $14,300.00)

1965 shelby shelby(US $14,300.00)

Auto Services in Arizona

yourcarguyaz.com ★★★★★

VW & Audi Independent Service and Repair Specialist ★★★★★

USA Auto Glass Repair ★★★★★

Truck And Trailer Parts Incorporated ★★★★★

Tony`s Auto Repair ★★★★★

TintAZ.com Mobile Window Tinting ★★★★★

Auto blog

Question of the Day: Most degraded car name?

Fri, May 27 2016When Ford came up with a not-so-sporty version of the Pinto and slapped Mustang badges on it in 1974, that was a low point for the Mustang name. When Chrysler applied the venerable Town & Country name on perfectly functional but unglamorous minivans, it saddened many of us. But perhaps the biggest demotion for a once-proud model came when, in 1988, General Motors imported a misery-enhancing Daewoo from Korea and called it the Pontiac LeMans. The original Pontiac LeMans was a great-looking midsize car with fairly advanced (for the time) suspension design and engine options including potent V8s and a screaming overhead-cam straight-six. The Daewoo-based Pontiac LeMans was a cramped, shoddy hooptie that served only to ruin the LeMans name forever, while stealing sales from the Suzuki-based Chevrolet Sprint. Sure, using the once-respected Monterey name on the Mercurized Ford Freestar was bad, but Mercury didn't have long to live at that point. I say the downward spiral of the LeMans name was the most agonizing in automotive history. What do you think? Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. Auto News Ford Mercury Pontiac Automotive History Classics questions ford pinto names

Jurassic Park made a big impact on these Jeep drivers

Thu, 12 Jun 2014For a certain cohort of young folks, Jurassic Park is a touchstone film from their childhood. Not only did it play into practically every little boy's love of dinosaurs, the movie included some great action scenes and special effects that still hold up today. In its latest video, The Aficionauto takes a look the Jurassic Park Motor Pool, a California car club with over 40 fans who created replica vehicles from the iconic film.

The club is made up of an interesting cross-section of people. Many of them were Jeep Wrangler fans that already loved off-roading and Jurassic Park, and liked the idea of bringing them together. Like any close-knit club, it ends up being about community and people coming together to share their interests. It's quite a heartwarming video. Also, be sure to stay until the end because The Aficionauto teases a future Jurassic Park-themed vehicle. Scroll down to check out the motor pool.

Forza Horizon 3 adds Ford Police Interceptor, Jeep CJ5

Tue, Oct 4 2016We're only a few weeks past the debut of Forza Horizon 3, and already the folks at Turn 10 are introducing the first of six car packs for the open-world driving game. Focused heavily on performance, there are still a few, um, oddballs, including one we're sure Forza's livery customizers will have a blast with. The Smoking Tire Car Pack brings seven new vehicles to FH3, with the Aston Martin Vulcan, Pagani Huayra BC, GTA Spano, Lotus 340R, and BMW M2 repping traditional performance vehicles. As per usual, FH3 renders each car beautifully and promises a solid approximation of real-world performance – even if you do ditch the roads and opt to rampage through the Australian countryside. While performance is good, the Ford Crown Victoria Police Interceptor and the Jeep CJ5 Renegade bring an off-beat vibe to this particular pack. We aren't certain, but this might be the first time the Police Interceptor appears in a blockbuster driving game. While we expect plenty of police car liveries for the Crown Vic, Forza's rabid community of tuners and customizers are sure to do much more with it. As for the CJ5, is there a better vehicle for tooling about Australia? Yeah, we didn't think so. The Smoking Tire Car Pack is available for free as part of the Forza Horizon 3 Ultimate Edition or Car Pass program. Commitment-phobes can also download this single vehicle pack for $7. Featured Gallery Forza Horizon 3: Smoking Tire Car Pack News Source: Turn 10 StudiosImage Credit: Turn 10 Studios Toys/Games Aston Martin BMW Ford Jeep Lotus turn 10 studios bmw m2 forza horizon ford crown victoria aston martin vulcan forza horizon 3 gta spano