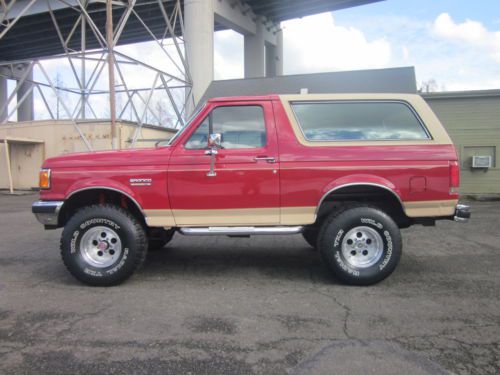

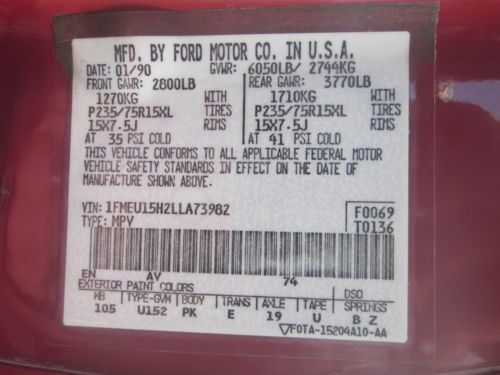

90 Ford Bronco Eddie Bauer No Reserve 4x4 5.8l V8 Lifted Extra Clean Tow Pack on 2040-cars

Portland, Oregon, United States

Ford Bronco for Sale

1996 ford bronco xlt sport utility 2-door 5.0l(US $3,900.00)

1996 ford bronco xlt sport utility 2-door 5.0l(US $3,900.00) 1972 bronco 4x4, lifted flowmasters, 302, ps/pb sweet machine!

1972 bronco 4x4, lifted flowmasters, 302, ps/pb sweet machine! 1994 ford bronco eddie bower 4x4(US $4,000.00)

1994 ford bronco eddie bower 4x4(US $4,000.00) 1978 1979 ford bronco ranger xlt 4x4 6.5" lift new 35" tires no rust(US $6,000.00)

1978 1979 ford bronco ranger xlt 4x4 6.5" lift new 35" tires no rust(US $6,000.00) 2 owners - power options - cold a/c - beautiful rust-free oregon classic bronco

2 owners - power options - cold a/c - beautiful rust-free oregon classic bronco At, pwr steering/ brakes, ca no rust, with original top and rear seat installed(US $16,000.00)

At, pwr steering/ brakes, ca no rust, with original top and rear seat installed(US $16,000.00)

Auto Services in Oregon

The Parkrose Garage ★★★★★

Racers Automotive ★★★★★

Portland Window Tinting ★★★★★

PM Automotive ★★★★★

Pioneer Auto Wholesale ★★★★★

Oregon Engine Rebuilders ★★★★★

Auto blog

What next for Alan Mulally?

Wed, 23 Apr 2014Alan Mulally has emerged as a hero when it comes to American manufacturing. He came to Ford in 2006 after serving as head of Boeing's commercial aircraft division, streamlined operations, sold off the costly elements of its Premier Automotive Group and saved Ford from having to be bailed out by the federal government like its cross-town rivals Chrysler and General Motors did. But as we reported mere days ago, he's widely expected to step down from the chief executive's office at Ford shortly.

So what's next for one of the most successful executives in the business? Hard to say, but don't expect Mulally to disappear into retirement. Though he didn't ultimately take the top job at Microsoft, industry insiders expect to see him in another influential position - likely as a board director or even chairman of another company. (We say "another company" and not Ford because while Bill Ford may have stepped aside as CEO to bring Mulally on board in the first place, we don't see him giving up his chairmanship of the board also.)

Mulally has likely already lined up his next move, and could either announce what that move will be as soon as Ford confirms Mark Fields as his successor, or could wait awhile. Insiders speculate that he could leverage his transportation and aerospace experience into a position at General Electric or a major airline, his manufacturing expertise to benefit a company like Procter & Gamble or his management skills at a consultancy firm.

Ford S-Max Concept previews new look, technology for Euro seven-seater

Wed, 28 Aug 2013Ford unveiled today the S-Max Concept, which comes with a new, sleek look and loaded with innovative technology, such as a heart-rate monitoring seat. But if you're heart is set on a minivan sports activity vehicle (SAV) and you live in the States, don't wait for this one - it's a Europe-only product, and we don't expect that to change when the next-gen S-Max is released.

The styling follows Ford's global design language, looking a bit like an overgrown Focus hatchback with the company's signature grille, wraparound headlamps, steeply raked windshield and curved roof line. Ford also implemented details to make the S-Max look longer and faster, such as a feature line on each side of the vehicle and muscular-looking fenders. The engine isn't Ford's most powerful, but the new 1.5-liter EcoBoost four-cylinder engine should be potent enough with turbocharging and other efficiency related technologies.

Ford says the new interior, which seats up to seven people, features high-quality materials and fine detailing, such as an "ultra-soft" leather wrap for the instrument panel and leather and carbon-fiber details on the seats. Ford's Sync connectivity system with MyFord Touch makes the car a wireless hotspot, and there's a tablet docking station for second-row occupants.

How Ford switched gears for the all-new F-150

Fri, Mar 6 2015Editor's Note: This story is authored by Julia Halewicz, a senior editor with AOL's Custom Solutions Group. She holds a Masters in Journalism from NYU and has spent her career as an editor of various newspapers, magazines and digital outlets. Last year on the Friday before Labor Day, the 2014 Ford F-150 pickup truck came off the Dearborn assembly line for the last time. After the last seam was welded, the F-150 that had been so beloved by American consumers would begin the transition from traditional steel manufacturing to an aluminum body, and the second phase of Ford's 2007 blueprint for sustainability would begin. Jobs would be created, and Ford would deliver a stronger product to its consumers. It was a moment Ford would call the biggest in the company's 111-year history. Breaking The Mold For some, the change was almost unfathomable. How could a truck be made with aluminum, and why change what clearly was working very well for the company? "We have a saying at Ford that leaders lead," said Doug Scott, the company's truck group marketing manager. "This was an ideal product to make with aluminum-alloy, because lightweighting made so much sense for a truck, because the extent to which you could take weight out of a truck, you could add more value to the customer in terms of more towing, more payload, more durability, more efficiency – so again all this required us to be out in front further out in front that we normally would be to make sure that we would deliver on all those expectations." Ford began the planning process about five years before the first aluminum F-150 would come to market. The company had a lot of questions. What was customer acceptance of aluminum, could they build the truck, and could the truck be repaired out in the field? Finally, Ford needed to determine if there were enough materials available to support the demand for the F-Series. Aluminum vehicles aren't unusual, but had never been built on the scale of the F-150 – approximately one every minute. Ford created two prototypes to determine if the product would meet and exceed consumer expectations. Any change to the vehicle had to be justified in performance, safety and economy. An aluminum truck needed to be safer, lighter, have increased payload, haul more, and have improved fuel efficiency. After driving the prototypes, Ford knew it was ready to move forward. Once the aluminum truck was ready to build, the next challenge was quickly transforming the plant.