1929 Ford Roadster Street Rod on 2040-cars

McAllen, Texas, United States

|

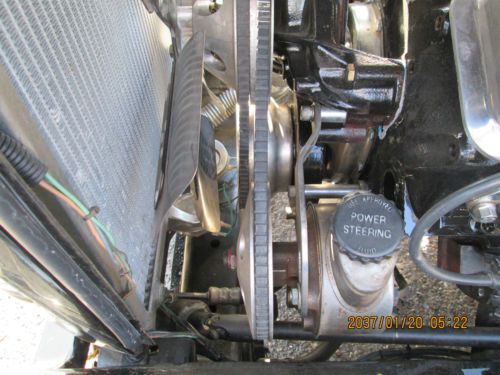

Hey there hot rod nation here is a really cool rod at a affordable price , freshly built , killer paint, mustang 2 front end, automatic turbo 350 trans, 350 Chevrolet crate motor , excellent professional interior , removable steering wheel to make it easier to get in and out , painted wire wheels , awesome hand painted pinstripes, canvas roadster top , excellent trunk area, good sound system , like new underneath , fiberglass body that is laser straight , the paint is as good as I have ever seen . it is a little tough to get in and out but I can do it easily at 5 10 170 pounds . it will take you a lot of work to build your own and a steel one in this condition is over 35000 dollars , I can help you get it shipped about any where in the world . any questions call jay at 956 624 2669 thanks . you will love this car

|

Ford Model T for Sale

Model t ford 1925 roadster

Model t ford 1925 roadster 1923 "t" bucket replica hot rod ford, similar to 22, 24, 25, 26, 27, 28, 29, 30

1923 "t" bucket replica hot rod ford, similar to 22, 24, 25, 26, 27, 28, 29, 30 1926 ford model t sedan concours quality restoration same owner 45 years(US $13,000.00)

1926 ford model t sedan concours quality restoration same owner 45 years(US $13,000.00) 1923 ford t,street rod, pick -up roadster(US $17,800.00)

1923 ford t,street rod, pick -up roadster(US $17,800.00) 1923 ford model t touring car

1923 ford model t touring car 1927 ford model t touring sedan convertible

1927 ford model t touring sedan convertible

Auto Services in Texas

Wynn`s Automotive Service ★★★★★

Westside Trim & Glass ★★★★★

Wash Me Car Salon ★★★★★

Vernon & Fletcher Automotive ★★★★★

Vehicle Inspections By Mogo ★★★★★

Two Brothers Auto Body ★★★★★

Auto blog

Suppliers love Toyota and Honda: Why that matters to you

Mon, May 15 2017You might think that a survey of automotive suppliers and their relationship with OEMs is the automotive equivalent of nerd prom. In some ways that's what the North American Automotive OEM-Supplier Working Relations Index (WRI) is. The study, the 17th annual conducted by Planning Perspectives Inc., is based on input from 652 salespeople from 108 Tier One suppliers, or, PPI points out, 40 of the top 50 automotive suppliers in North America. Suppliers to General Motors, Ford, FCA, Toyota, Honda, and Nissan. But the results have consequences in terms of tens of millions of dollars for OEMs - and in the quality, technology, and cost of the next vehicle you buy. There are a couple of ways to look at the results of the WRI. One is, "So what else is new?" And the other is, "Damn! How did that happen?" The study looks at five relationship areas — OEM Supplier Relationship; OEM Communication; OEM Help; OEM Hindrance; Supplier Profit Opportunity — within six purchasing areas — Body-in-White; Chassis; Electrical/Electronics; Exterior; Interior; Powertrain. In the overall rankings, Toyota is on top for the 15 th time in 17 years, with a score of 328. Honda, the only company to best Toyota (in 2009 and 2010), comes in second, at 319. Those two companies, explains John Henke, president of PPI, have collaborative working arrangements with colleagues and suppliers alike built into the very fabric of their cultures. This, however, is not a situation where one can readily conclude it is about "Japanese companies," because the third company with headquarters on the island of Honshu, Nissan, came in dead last. This is the "How did that happen?" portion. The Nissan score of 203 puts it 125 points behind Toyota. There hasn't been a number that low since the then-Chrysler Corp. scored 187 in 2010, when the company was clawing its way out of the recession. Clearly, the suppliers don't feel particularly engaged by the buyers at Nissan. Henke explains that whether a company does well or not on the WRI is rather simple. All people do things based on what they're measured on. "If you're measured on taking 10% out of your annual buy, you immediately know how to do it. But if you're also measured on improving relations, suddenly there is a new dynamic as to what you can do to achieve both.

Recharge Wrap-up: Tesla details factory expansion; Ford and SunPower raise money for Sierra Club

Thu, Nov 20 2014Tesla has revealed the details of the upgrade of its Fremont, CA factory. One major change is the addition of a dedicated production space for the dual-motor P85D version of the Model S. Robots will be doing the battery installation on the Model S to save some time, and new export docks allow Tesla to get the cars out the door and on the way to their new owners more quickly. The new robots that move the cars around the factory have been named after X-Men characters, which makes our inner geeks smile. Check out the factory upgrade in the time-lapse video below and read more at Teslarati or at the Tesla Motors Blog. A program in Beijing for privileged registrations for EVs hasn't had much success. Of the 1,424 lottery winners, only about 30 percent went on to register an electric car despite a two-month extension of the deadline to do so. Buyers are likely discouraged by the lack of charging infrastructure, which the city hopes to ameliorate with the addition of 1,000 new charging stations by the end of the year, and by requiring new and renovated developments to set aside parking specifically for EV charging. Read more at Green Car Reports. The UC Davis Institute of Transportation Studies suggests that laws designed to protect dealers and consumers are stymieing the adoption of EVs. Laws like the ones certain states have in place that block or otherwise restrict Tesla's direct-to-consumer business model are not helpful for companies that want to introduce new products to the market. They prevent companies from passing on savings to customers for whom they would likely make the difference in a purchasing decision. One possible solution would be to allow exemptions to certain selling restrictions for a certain number of vehicles sold. "This could give automakers the degree of control needed to work out kinks with early customers, develop scalable processes for supporting PEVs, and ensure that effective dealer performance standards are in place before handing the reins over to wholly independent retailers," according to UC Davis ITS. Read more at the UC Davis website. Volkswagen says its environmental program, called "Think Blue. Factory," is meeting the automaker's own sustainability targets. The main purpose of the program is to move toward eco-friendlier carmaking at each of its plants worldwide.

Ford, Alcoa announce next generation of aluminum lightweighting for F-150

Thu, Sep 17 2015Ford likes what it has seen with the use of aluminum in its world-beating F-150 pickup trucks. Now, the Blue Oval is working with Alcoa to use that company's Micromill material to increase the amount of aluminum in Ford vehicles. In fact, Ford will start using Micromill on 2016 model-year F-150s later this year, and will double the material's use in 2017. The purpose, as you might suspect, is light weighting, which allows Ford to boost towing capacity while adding as little weight as possible. Ford will be the first automaker to use Micromill, and will use it in both structural components and exterior panels. Micromill's rolling-mill system cuts the time it takes to turn molten metal into coil to 20 minutes from about 20 days. Already, Ford has had positive results by using aluminum on its leading pickup truck model. In April, it was announced that the 2015 Ford F-150 achieved a five-star Overall Vehicle Score in the National Highway Traffic Safety Administration's testing. Safety features like inflatable seat belts, adaptive steering columns and a forward collision warning system helped matters. General Motors may have taken note of those results, even after running an ad campaign touting its continued use of steel over aluminum. Last month, GM said it would sink $877 million into its Flint, MI, truck factory. Reuters said much of the expense was to convert many of the bodies for models like the Chevrolet Silverado and GMC Sierra pickups into aluminum. You can take a look at Ford's press release below. Ford Motor Company and Alcoa Inc. are collaborating to produce next-generation automotive aluminum alloys that are more formable and design-friendly. Ford will use Alcoa's Micromill® material in multiple components on the 2016 F-150 – becoming the first automaker to use the advanced automotive aluminum commercially. The companies entered into a joint development agreement to collaborate on next-generation aluminum alloys for automotive parts using Micromill™ technology. ''Light-weighting enables us to design vehicles with great customer attributes – like the F-150, which can tow more, haul more, accelerate quicker and stop faster than the previous F-150, and is more fuel-efficient than ever," said Raj Nair, Ford group vice president and chief technical officer, Global Product Development.