12 Ford F150 4x2, Xlt, Crew Cab, Cloth, Tow Package, We Finance on 2040-cars

Austin, Texas, United States

Vehicle Title:Clear

Vehicle Inspection: Vehicle has been Inspected

Make: Ford

CapType: <NONE>

Model: F-150

FuelType: Gasoline

Mileage: 23,171

Listing Type: Certified Pre-Owned

Sub Model: 2WD

Certification: Manufacturer

Exterior Color: White

Interior Color: Tan

BodyType: Pickup Truck

Cylinders: 6 - Cyl.

Warranty: Warranty

DriveTrain: REAR WHEEL DRIVE

Ford F-150 for Sale

2009 ford f-150 extended cab 5.4l v8 cruise ctrl 47k mi texas direct auto(US $15,980.00)

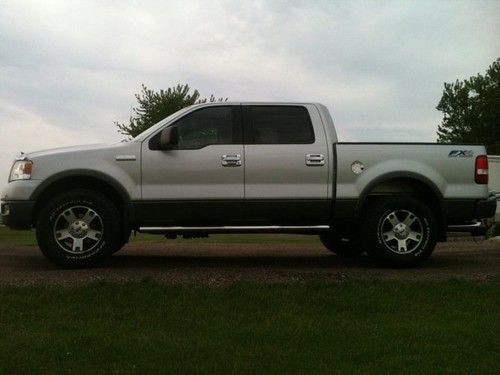

2009 ford f-150 extended cab 5.4l v8 cruise ctrl 47k mi texas direct auto(US $15,980.00) 2005 ford f-150 fx4 crew cab pickup 4-door 5.4l(US $12,500.00)

2005 ford f-150 fx4 crew cab pickup 4-door 5.4l(US $12,500.00) 2013 xlt texas edition crew 4x4 gray cloth v6 ecoboost sync lifetime warranty(US $35,143.00)

2013 xlt texas edition crew 4x4 gray cloth v6 ecoboost sync lifetime warranty(US $35,143.00) 2005 f-150 xlt supercrewcab 2wd(US $16,000.00)

2005 f-150 xlt supercrewcab 2wd(US $16,000.00) 1998 xlt 5.4l auto maroon

1998 xlt 5.4l auto maroon 2013 xlt texas edition crew 4x4 gray cloth v6 ecoboost sync lifetime warranty(US $35,143.00)

2013 xlt texas edition crew 4x4 gray cloth v6 ecoboost sync lifetime warranty(US $35,143.00)

Auto Services in Texas

Zepco ★★★★★

Z Max Auto ★★★★★

Young`s Trailer Sales ★★★★★

Woodys Auto Repair ★★★★★

Window Magic ★★★★★

Wichita Alignment & Brake ★★★★★

Auto blog

Ford sued over alleged 3.5-liter EcoBoost defects

Thu, 16 May 2013Three Ford owners from Ohio have filed a lawsuit against the automaker over defects that they allege exist within the company's twin-turbocharged 3.5-liter V6 EcoBoost engine. Automotive News reports that the lawsuit claims the engine "contained serious latent design, manufacturing, or assembly defects." Those defects, the suit claims, cause the vehicle to shake, misfire and lose power quickly.

Two of the plaintiffs, a married couple, own a 2010 Ford Taurus SHO, and allege they experienced a loss of power and stalling, while the third, an F-150 owner, claims he lost power while accelerating. In addition to the Taurus SHO and F-150, the 3.5-liter V6 EcoBoost engine is also available in the Ford Flex, Explorer Sport and Lincoln MKT and MKS. Other three- and four-cylinder EcoBoost engines are not included in the suit. There have been no recalls associated with 3.5-liter V6 engine, and the National Highway Traffic Safety Administration is currently not investigating the matter.

The plaintiffs, however, claim Ford has known about the problem, citing several technical service bulletins issued to dealers of the F-150 that suggest possible fixes. Ford had no comment for Automotive News, saying that it's yet to review the lawsuit, which was filed last Friday in Columbus, OH.

Ford shutters Genk assembly plant in Belgium

Tue, Dec 23 2014Ford has become the latest automaker to close one of its European assembly plants. The facility in question is located in the Belgian city of Genk and has been in operation since the early '60s when it started building the Taunus, Ford's first mass-produced, front-drive model. As part of the plan first announced over two years ago, the Genk Body & Assembly Plant is now closing its doors after half a century in the business and over fourteen million vehicles built. Although the plant itself employed some 5,000 workers, once you take into account the suppliers built up around the plant, the overall impact on employment in the area edges closer to 12,000. Genk Body & Assembly had until recently been tasked with producing the Mondeo sedan (which in its current iteration we know as the Fusion) as well as the S-Max and Galaxy minivans. Production of the Mondeo shifted in 2013 to the company's plant in Valencia, Spain, which also handles the Kuga crossover and Transit Connect cargo van, and will soon take over the minivans from Genk as well. The move follows a similar decision undertaken by General Motors to close the Opelwerk plant in Bochum, Germany. It also reflects a scaling down of automobile production in Belgium specifically: although Audi still manufacturers in Brussels and and Volvo in Ghent, Opel closed its plant in Antwerp in 2000 and Renault ceased production in Vilvoorde back in '97. However Ford still maintains its famous proving ground half an hour to the north in Lommel, Belgium. News Source: AutovisieImage Credit: Kristof Van Accom / AFP / Getty Plants/Manufacturing Ford plant ford s-max ford galaxy

Aluminum lightweighting does, in fact, save fuel

Mon, Apr 14 2014When the best-selling US truck sheds the equivalent weight of three football fullbacks by shifting to aluminum, folks start paying attention. Oak Ridge National Laboratory took a closer look at whether the reduced fuel consumption from a lighter aluminum body makes up for the fact that producing aluminum is far more energy intensive than steel. And the results of the study are pretty encouraging. In a nutshell, the energy needed to produce a vehicle's raw materials accounts for about 10 percent of a typical vehicle's carbon footprint during its total lifecycle, and that number is up from six percent because of advancements in fuel economy (fuel use is down to about 68 percent of total emissions from about 75 percent). Still, even with that higher material-extraction share, the fuel-efficiency gains from aluminum compared to steel will offset the additional vehicle-extraction energy in just 12,000 miles of driving, according to the study. That means that, from an environmental standpoint, aluminum vehicles are playing with the house's money after just one year on the road. Aluminum-sheet construction got topical real quickly earlier this year when Ford said the 2015 F-150 pickup truck would go to a 93-percent aluminum body construction. In addition to aluminum being less corrosive than steel, that change caused the F-150 to shed 700 pounds from its curb weight. And it looks like the Explorer and Expedition SUVs may go on an aluminum diet next. Take a look at SAE International's synopsis of the Oak Ridge Lab's study below. Life Cycle Energy and Environmental Assessment of Aluminum-Intensive Vehicle Design Advanced lightweight materials are increasingly being incorporated into new vehicle designs by automakers to enhance performance and assist in complying with increasing requirements of corporate average fuel economy standards. To assess the primary energy and carbon dioxide equivalent (CO2e) implications of vehicle designs utilizing these materials, this study examines the potential life cycle impacts of two lightweight material alternative vehicle designs, i.e., steel and aluminum of a typical passenger vehicle operated today in North America. LCA for three common alternative lightweight vehicle designs are evaluated: current production ("Baseline"), an advanced high strength steel and aluminum design ("LWSV"), and an aluminum-intensive design (AIV).