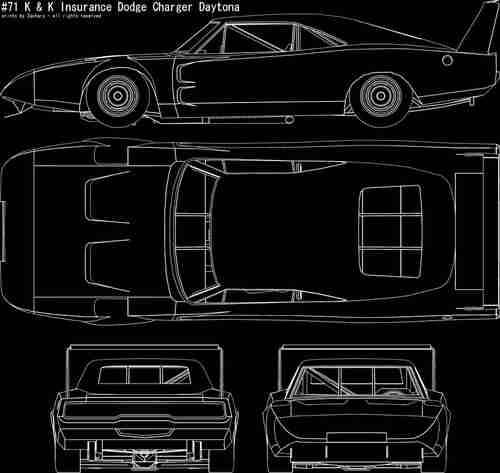

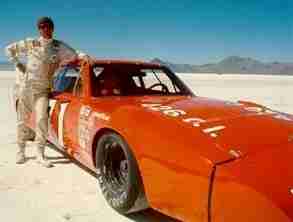

1969 Nascar Dodge Daytona Jet Turbine Resto-mod on 2040-cars

Hesperia,CA, United States

Body Type:Coupe

Vehicle Title:Clear

Fuel Type:MULTI-FUEL

Engine:Lycoming LTS-101 Jet Turbine

For Sale By:Private Seller

Make: Dodge

Model: Charger

Trim: DAYTONA-NASCAR Resto-Mod !

Drive Type: Custom

Number of Doors: 2

Mileage: 123,567

Warranty: Unspecified

Exterior Color: Flat Black

Dodge Charger for Sale

2007 dodge charger sxt sedan 4-door 3.5l awd 18" polished factory rims

2007 dodge charger sxt sedan 4-door 3.5l awd 18" polished factory rims (US $45,000.00)

(US $45,000.00) 1979 dodge ram charger rare california teal vintage vhtf

1979 dodge ram charger rare california teal vintage vhtf 2012 dodge charger police-spec (rare) rt

2012 dodge charger police-spec (rare) rt 2007(07)charger we finance bad credit! buy here pay here low down $2195 ez loan(US $14,997.00)

2007(07)charger we finance bad credit! buy here pay here low down $2195 ez loan(US $14,997.00) 2012 dodge charger 4dr sdn se rwd(US $22,491.00)

2012 dodge charger 4dr sdn se rwd(US $22,491.00)

Auto blog

Lee Iacocca's very first Dodge Viper RT/10 nets $285,500 at auction

Fri, Jan 17 2020The first 1992 Dodge Viper RT/10 to roll down the assembly line, which was snapped up by Chrysler chief Lee Iacocca, yesterday hammered at the Bonhams auction in Arizona for $285,500, more than double the pre-sale estimate. According to a history of the car published by the auction house, Iacocca, in his introduction of the Viper to the press, pointed to the car on stage and said, "This one right here is mine." That historic Viper, with serial number 001, has never been available on the open market, as Iacocca kept the car from new until he passed away last year. The car has been driven just 6,200 miles and was being sold by his estate. Other Lee Iacocca cars offered at the same sale fared less well. A 1986 Chrysler LeBaron Town & Country convertible — the ultimate expression of Iacocca's company-saving K-cars — with 20,500 miles on it sold for $19,040. That's less than the $20,000 to $25,000 the auction house had estimated the car would bring. A third car from the former auto executive's estate was a customized 2009 Ford Mustang. The pony car was one of a limited run of 45 Iacocca-branded custom Mustangs, which were reworked by Metalcrafters and sold by Galpin Ford in Los Angeles. The Iacocca Mustang, never titled and with 220 miles on it, hammered for $49,280. Related Video:   Featured Gallery Lee Iacocca's 1992 Dodge Viper RT/10 View 13 Photos Celebrities Chrysler Dodge Auctions Automotive History

2013 Dodge Charger AWD Sport

Tue, 29 Jan 2013We won't beat around the bush: The all-wheel-drive Dodge Charger is not a brand new car. This generation launched in 2011, AWD models and all. But for 2013, Chrysler has added an optional sport package to the AWD model, available with both the 3.6-liter Pentastar V6 or the sweet, sweet 5.7-liter Hemi V8. The upgrades for this new sport pack are mainly cosmetic; a gloss black grille, new 19-inch alloy wheels and body-colored rear spoiler make up the list of exterior changes. Inside, there are new sport seats and paddle shifters, and the eight-speed automatic transmission has been reflashed for better performance.

But because vehicles like the Dodge Charger mainly stick out in our minds as being rear-drive bruisers, Chrysler wanted to give us the opportunity to test out the LX platform's foul-weather prowess. And perhaps no place more appropriate to test such a system was way up in Michigan's Upper Peninsula in the dead of winter.

Driving Notes

2019 Dodge Durango GT Blacktop | Blacked-out family hauler

Wed, Jul 25 2018We recently spent a day at FCA's Chelsea Proving Grounds here in Michigan, and after we had had a little too much fun driving the new 2019 Dodge Durango Pursuit, we took a ride in the updated Durango GT. New for 2019, the GT gets a new front fascia borrowed from its R/T and SRT brethren. It also gets standard LED fog lamps. The optional performance hood is inspired by the SRT model, with a single air duct and two heat extractors. In the rear. In addition to its updated styling, this tester was equipped with the Blacktop package, which gives the sporty new flair a menacing edge. It had glossy black wheels (20-inchers) and mirrors, and blacked-out badges on the exterior. At the rear, it had dual exhaust with bright tips. Inside, out tester featured carbon fiber accents, paddle shifters and a trailer brake control. The Dodge Durango GT is still powered by the 3.6-liter Pentastar V6, producing 295 horsepower and 260 pound-feet of torque. It's available in rear- and all-wheel-drive configurations, and can tow up to 6,200 pounds. It shifts gears via an eight-speed automatic transmission. RWD models get 19 mpg city, 26 highway, and AWD models suffer one mpg across the board. Our brief drive reconfirmed what we already knew about the Durango. It's a fun SUV that feels macho yet comfortable. For a vehicle that size, it really is fun to drive, and Dodge did a great job of making it feel like a lifted Charger. It's got plenty of room for the whole family, but you won't have to check your soul at the door. Have a gander at the video above, and be on the lookout for more videos coming from our day at FCA's proving grounds.Related Video: