01 Pt 2.4l L4 Sfi Dohc 16v Taupe Frost Metallic on 2040-cars

Lansdale, Pennsylvania, United States

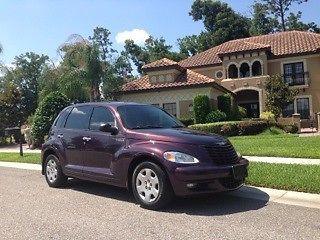

Chrysler PT Cruiser for Sale

2005 chrysler pt cruiser base wagon 4-door 2.4l

2005 chrysler pt cruiser base wagon 4-door 2.4l Black/gray chrome package. limited addition(US $5,500.00)

Black/gray chrome package. limited addition(US $5,500.00) Leather interior low miles chrome wheels moonroof(US $3,999.00)

Leather interior low miles chrome wheels moonroof(US $3,999.00) 4dr wgn low miles sedan automatic gasoline 2.4l dohc smpi 16-valve i4 engine sur

4dr wgn low miles sedan automatic gasoline 2.4l dohc smpi 16-valve i4 engine sur Chrysler pt cruiser 2005 white touring edition

Chrysler pt cruiser 2005 white touring edition 2007 chrysler pt cruiser 4dr only 98k miles very nice gas saver automatic clean

2007 chrysler pt cruiser 4dr only 98k miles very nice gas saver automatic clean

Auto Services in Pennsylvania

Yorkshire Garage & Auto Sales ★★★★★

Willis Honda ★★★★★

Used Car World West Liberty ★★★★★

Usa Gas ★★★★★

Trone Service Station ★★★★★

Tri State Preowned ★★★★★

Auto blog

Marchionne's FCA-GM merger might come after Ferrari spinoff

Sat, Sep 5 2015Sergio Marchionne is continuing to rumble about working out a merger with General Motors, but don't expect anything big to happen before at least early next year. That's because Marchionne would likely wait for the Ferrari spin-off to be complete before beginning his next big deal, according to Automotive News. While the Ferrari IPO on the New York Stock Exchange is expected in the coming weeks, that only concerns 10 percent of the shares. The remaining 80 percent of stock is being distributed among shareholders in 2016. Piero Ferrari holds the final 10 percent with no intention to sell. This strategy allows FCA to claim 80 percent of the Prancing Horse's profits in the automaker's 2015 financial results. According to Automotive News, the tactic has other advantages, as well. FCA would be flush with cash by waiting for the spin-off to be complete, and it would keep Ferrari separate if a GM merger actually happens. Marchionne thinks Ferrari could be valued at over $11 billion in the IPO, and it could make FCA $3.3 billion richer when complete. Marchionne believes a combined FCA/GM could sell 17 million vehicles a year globally and rake in $30 billion in earnings. In the CEO's opinion, the two automakers are wasting money by developing components to do the same things on their vehicles. Although, so far the General's top execs are rebuffing all of his advances.

Chrysler launches new Ram ads and gears up for Super Bowl XLV [w/videos]

Tue, 09 Oct 2012Perhaps no car company has made bigger splashes in the last two years at the Super Bowl than Chrysler, and the automaker's marketing chief, Olivier Francois, said today that he plans to be all over the big game again in February.

Last year, the company made an ad featuring Hollywood icon Clint Eastwood. The spot achieved viral status quickly when pundits charged that Eastwood's lines were politically motivated; meant to appeal to progressive voters/viewers favoring a second term for President Obama. In 2011, agency Wieden & Kennedy burst into the game with a now famous commercial featuring Eminem. Both ads have supported Chrysler's "Imported from Detroit" marketing platform.

Francois briefed reporters Monday at the Detroit Opera House while he also debuted a new series of ads for the Ram brand.

Zombie cars: A dozen discontinued vehicles people still buy new

Thu, Jan 6 2022Car models come and go, but as revealed by monthly sales data, once a car is discontinued, it doesn't just disappear instantly. And in the case of some models, vanishing into obscurity can be a slow, tedious process. That's the case with the 12 cars we have here. All of them have been discontinued, but car companies keep racking up "new" sales with them. There are actually more discontinued cars that are still registering new sales than what we decided to include here. We kept this list to the oldest or otherwise most interesting vehicles still being sold as new, including a supercar. We'll run the list in alphabetical order, starting with *drumroll* ... BMW 6 Series: 55 total sales BMW quietly removed the 6 Series from the U.S. market during the 2019 model year. It had been available in three configurations, a hardtop coupe, a convertible and a sleek four-door coupe-like shape. BMW i8: 18 total sales We've always had a soft spot for the BMW i8, despite the fact that it never quite fit into a particular category. It was sporty, but nowhere near as fast as similarly-priced competitors. It looked very high-tech and boasted a unique carbon fiber chassis design and a plug-in hybrid powertrain, but wasn't really designed for maximum efficiency or maximum performance. Still, the in-betweener was very cool to look at and drive, and 18 buyers took one home over the course of 2021. Chevy Impala: 750 total sales The Impala represented classic American tastes at a time when American tastes were shifting away from soft-riding sedans with big interior room and trunk space and into higher-riding crossovers. A total of 750 sales were inked last year. Chrysler 200: 15 total sales The Chrysler 200 was actually a pretty nice sedan, with good looks and decent driving dynamics let down by a lack of roominess, particularly in the back seat. Of course, as we said regarding the Chevy Impala, the number of Americans in the market for sedans is rapidly winding down, and other automakers are following Chrysler's footsteps in canceling their slow-selling four-doors. Even if Chrysler never really found its footing in the ultra-competitive midsize sedan segment, apparently dealerships have a few leftover 2017 200s floating around. And for some reason, 15 buyers decided to sign the dotted line to take one of these aging sedans home last year.