1970 Chevrolet Nova on 2040-cars

Toledo, Ohio, United States

Body Type:Coupe

Engine:350 V-8

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Private Seller

Interior Color: Black

Make: Chevrolet

Number of Cylinders: 8

Model: Nova

Trim: 2 Door Sedan

Warranty: Vehicle does NOT have an existing warranty

Drive Type: RWD

Mileage: 500

Exterior Color: Green

Chevrolet Nova for Sale

1970 chevrolet nova ss real deal documented and loaded with options 350 v8 300hp(US $22,975.00)

1970 chevrolet nova ss real deal documented and loaded with options 350 v8 300hp(US $22,975.00) 1966 chevy nova ii - full restoration - 72,000 1-owner car

1966 chevy nova ii - full restoration - 72,000 1-owner car 1962 chevy ii "400" convertible: excellent project car...(US $7,000.00)

1962 chevy ii "400" convertible: excellent project car...(US $7,000.00) 1967 nova 2door sedan

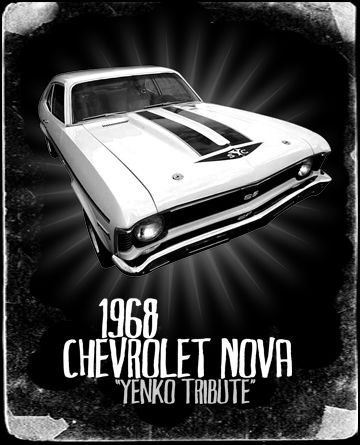

1967 nova 2door sedan 1968 chevy ii nova big block - yenko tribute (see video!)(US $25,995.00)

1968 chevy ii nova big block - yenko tribute (see video!)(US $25,995.00) Rotisserie restored resto-mod, 454, l-88 heads, 4speed, 23130 original miles..

Rotisserie restored resto-mod, 454, l-88 heads, 4speed, 23130 original miles..

Auto Services in Ohio

Zink`s Body Shop ★★★★★

XTOWN PERFORMANCE ★★★★★

Wooster Auto Service ★★★★★

Walker Toyota Scion Mitsubishi Powersports ★★★★★

V&S Auto Service ★★★★★

True Quality Collision ★★★★★

Auto blog

Chevy Bolt will go into production in Michigan in 2016 [UPDATE]

Fri, Feb 6 2015While nothing official has been announced, it appears that General Motors may actually put the all-electric Chevy Bolt into production next year. That's the rumor that Reuters is reporting, citing two sources at suppliers for the upcoming $30,000 EV (although that $30,000 number bears some scrutiny). This rumor does fit in with earlier comments that the Bolt would arrive on the market in 2017. If it gets built, the Bolt will share more than a similar-sounding name with the Chevy Volt: the EV will be put together in metro Detroit. Reuters says the 200-mile electric car (and an Opel version) will be made in "an underused small-car plant north of Detroit," which means the Orion Township plant. GM could make between 25,000 and 30,000 Bolts a year there, if what the suppliers are saying is true. We have asked GM for a statement on this story and will update it if we hear back. UPDATE: General Motors manager of electrification technology communications, Kevin Kelly, told AutoblogGreen that, "Bolt EV Concept is just that – a concept. We're currently evaluating the vehicle program, but do not have any production announcements to make at this time."

Autoblog's Editors' Picks: Our complete list of the best new vehicles

Mon, May 13 2024It's not easy to earn an “EditorsÂ’ Picks” at Autoblog as part of the rating and review process that every new vehicle goes through. Our editors have been at it a long time, which means weÂ’ve driven and reviewed virtually every new car you can go buy on the dealer lot. There are disagreements, of course, and all vehicles have their strengths and weaknesses, but this list features what we think are the best new vehicles chosen by Autoblog editors. We started this formal review process back in 2018, so there's quite of few of them now. So what does it mean to be an EditorsÂ’ Pick? In short, it means itÂ’s a car that we can highly recommend purchasing. There may be one, multiple, or even zero vehicles in any given segment that we give the green light to. What really matters is that itÂ’s a vehicle that weÂ’d tell a friend or family member to go buy if theyÂ’re considering it, because itÂ’s a very good car. The best way to use this list is is with the navigation links below. Click on a segment, and you'll quickly arrive at the top rated pickup truck or SUV, for example. Use the back button to return to these links and search in another segment, like sedans. If youÂ’ve been keeping up with our monthly series of the latest vehicles to earn EditorsÂ’ Pick status, youÂ’re likely going to be familiar with this list already. If not, welcome to the complete list that weÂ’ll be keeping updated as vehicles enter (and others perhaps exit) the good graces of our editorial team. We rate a new car — giving it a numerical score out of 10 — every time thereÂ’s a significant refresh or if it happens to be an all-new model. Any given vehicle may be impressive on a first drive, but we wait until itÂ’s in the hands of our editors to put it through the same type of testing as every other vehicle that rolls through our test fleet before giving it the EditorsÂ’ Pick badge. This ensures consistency and allows more voices to be heard on each individual model. And just so you donÂ’t think weÂ’ve skipped trims or variants of a model, we hand out the EditorsÂ’ Pick based on the overarching model to keep things consistent. So, when you read that the 3 Series is an EditorsÂ’ Pick, yes, that includes the 330i to the M3 and all the variants in between. If thereÂ’s a particular version of that car we vehemently disagree with, we make sure to call that out.

Chevy to reveal new Spark in Seoul and New York

Mon, Mar 9 2015Chevy is preparing to roll out an all-new Spark next month, giving us a taste of things to come with the teaser image above. The new Spark is set to debut simultaneously at car shows in Seoul and in New York on April 2, joining the new Malibu that will also mark its debut at the Manhattan expo. Why introduce the new Spark at the same time in South Korea and in the US, you ask? Probably because those are the two biggest markets for Chevy's smallest car, accounting for the lion's share of the 1.1 million units sold in 71 markets around the world since its introduction in 2009. Chevy hasn't revealed much about the new Spark, except to say that its styling will be more sophisticated than the "youthful whimsy" of the current model. A Spark of Sophistication Chevrolet's redesigned global minicar to debut in Seoul and New York on April 2 2015-03-09 DETROIT – The all-new 2016 Spark will debut on April 2 at the Seoul and New York auto shows, Chevrolet announced today. A sleeker, more aerodynamic profile and a progressive take on Chevrolet's signature design cues will give the redesigned Spark a more sophisticated aesthetic that reflects the changing tastes of the global minicar market. "The new Spark's design has evolved and grown up with the segment," said Michael Simcoe, GM International vice president of Design. "The youthful whimsy of the original Spark is still in its genes, but it is conveyed in more traditional proportions that reinforce the customer's refined expectations." Chevrolet has sold more than 1.1 million Sparks around the world since it went on sale as the Beat in India in late 2009. Today, the Spark is available in 71 markets worldwide, selling the most in South Korea, followed by the United States and Mexico. Spark is attracting younger and first-time car buyers to Chevrolet with 26 percent being under the age of 35. Sales of the Spark in the U.S. are up 32 percent in the first two months of 2015 versus the same period in 2014. Founded in 1911 in Detroit, Chevrolet is now one of the world's largest car brands, doing business in more than 115 countries and around 4.8 million cars and trucks a year. Chevrolet provides customers with fuel-efficient vehicles that feature engaging performance, design that makes the heart beat, passive and active safety features and easy-to-use technology, all at a value. More information on Chevrolet models can be found at www.chevrolet.com.