2013 Chevy Impala Ltz on 2040-cars

Farnhamville, Iowa, United States

|

I have a 2013 Impala LTZ for sale. I bought this car back in May now need to sell it to help with my daughters college tuition.

Here are the features...

|

Chevrolet Impala for Sale

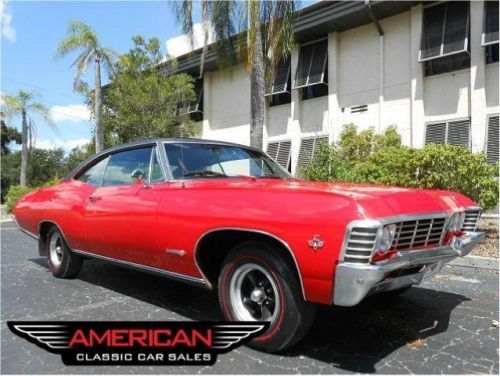

63 impala coupe super sport restored fresh engine auto ps buckets console clean!(US $23,455.00)

63 impala coupe super sport restored fresh engine auto ps buckets console clean!(US $23,455.00) Real super sport 350 auto red/black. super nice paint and body restored car fl(US $17,855.00)

Real super sport 350 auto red/black. super nice paint and body restored car fl(US $17,855.00) #s matching 1964 ss impala 409 ac posi project

#s matching 1964 ss impala 409 ac posi project 1966 chevy impala(US $4,700.00)

1966 chevy impala(US $4,700.00) 2005 chevrolet impala only 75k miles white exterior grey interior

2005 chevrolet impala only 75k miles white exterior grey interior 1965 chevrolet impala sports coupe(US $15,950.00)

1965 chevrolet impala sports coupe(US $15,950.00)

Auto Services in Iowa

Woody`s Automotive Upholstery ★★★★★

Shaffer`s Auto Body Co. Inc ★★★★★

Scotty`s Body Shop ★★★★★

Midwest Auto Repair Ctr ★★★★★

Midtown Auto Repair ★★★★★

Magic Mufflers & Brakes ★★★★★

Auto blog

Chevy to resume engine-building program for 2015 Corvette Z06

Thu, Jan 8 2015One of Chevrolet's most popular and unique customer features is set to return for 2015, as the company has announced that the Engine Build Experience is back. Interested owners will be able to screw together their engines beginning in March. The $5,000 option (which does not include the cost of travel) will give future owners of the 2015 Corvette Z06 the chance to screw together their car's actual 6.2-liter, supercharged V8. Available on each of the Z06's three trims, the Engine Build Experience includes a day at the Performance Build Center, instruction from an engine assembly tech, photographs of the experience and a personalized engine plaque. Once the build process is completed, the engine will (eventually) be fitted under the hood of the customer's personal Z06. "Chevrolet recognizes the passion customers have for Corvette and the Engine Build Experience offers them a truly unique opportunity for hands-on involvement in the creation of the heart of their new car," Corvette product manager Harlan Charles. "It's important for customers to understand their engine won't be installed the day after they built it. It will flow into the scheduling process for vehicle assembly, which depends on a number of logistical variables." Scroll down for the official announcement of the Z06's Engine Build Experience, available below. Exclusive Corvette Engine Build Experience Returns Program renewed for supercharged LT4 engine at new Bowling Green build center 2015-01-07 BOWLING GREEN, Ky. – Chevrolet announced today it is resuming the exclusive Engine Build Experience for Corvette Z06 customers – the only program of its kind for supercar customers. Starting in March 2015, Corvette Z06 customers will be able to assemble the 650-hp supercharged LT4 engine for their cars at the new Performance Build Center inside the Bowling Green Assembly Plant. "Chevrolet recognizes the passion customers have for Corvette and the Engine Build Experience offers them a truly unique opportunity for hands-on involvement in the creation of the heart of their new car," said Harlan Charles, Corvette product manager. "It's a chance to bond with their new car." The Engine Build Experience is selected with order code PBC and is offered on all Z06 trim levels.

GM profit dips on truck changeover, but beats estimates

Thu, Apr 26 2018DETROIT — General Motors on Thursday reported a higher-than-expected quarterly profit despite a drop in production of high-margin pickup trucks, as it gears up for new models that are expected to boost profits next year. Like rivals Ford and Fiat Chrysler Automobiles, GM is banking on highly-profitable Chevy Silverado and GMC Sierra pickup trucks to lift profits, as consumers shift away from traditional passenger cars in favor of these larger, more comfortable trucks, SUVs and crossovers. During the first quarter, the process of changing over to GM's new pickups resulted in a drop in production of 47,000 units. GM Chief Financial Officer Chuck Stevens said the production drop had resulted in a drop in pre-tax profit of up to $800 million. Earlier this year, GM said its 2018 profits would be flat compared with 2017, but expected its all-new pickup trucks would boost margins starting in 2019. On Thursday, GM reiterated its full-year 2018 forecast for adjusted earnings in a range from $6.30 to $6.60 per share. The automaker said capital expenditures were more than $500 million higher in the quarter because of investments its new pickup trucks and a family of low-cost vehicles under development with Chinese partner SAIC Motor Corp. On Wednesday, rival Ford said it would stop investing in most traditional passenger sedans in North America. CFO Stevens told reporters on Thursday that GM has "already indicated that we will make significantly lower investments on a go-forward basis" in sedans. 2019 GMC Sierra View 21 Photos GM benefited from a lower effective tax rate in the quarter, but adjusted pre-tax margin fell to 7.2 percent from 9.5 percent a year earlier. Stevens said the company's profit margin should hit 10 percent or higher in the second quarter and for the full year. GM said material costs were $700 million higher in the first quarter, and it expects those costs to continue rising. The automaker said it would counter those increases with cost cutting measures. "It is a more difficult environment than it was three or four months ago," Stevens said when asked about rising commodity prices from potential steel and aluminum tariffs announced by the Trump administration. "But we are confident we can continue to offset that." The company reported quarterly net income of $1.05 billion or $1.43 per share, a drop of nearly 60 percent from $2.61 billion or $1.75 per share a year earlier. Analysts had on average expected earnings per share of $1.24.

GM adds 1,200 jobs at Detroit-Hamtramck plant

Thu, Oct 22 2015General Motors is making a big move at its Hamtramck, MI, factory, announcing it will add a second shift and hire over 1,200 workers within the next several months. It's expected that by early 2016, the factory will employ over 2,800 workers to build the Chevrolet Volt, Impala, Malibu, Cadillac ELR, and by early next year, the new CT6. According to GM Hamtramck spokesperson Courtney Zemke, 40 of the 1,200 positions are for salaried employees, while the remainder will be hourly positions. As for where these employees will go, positions are being made available across the factory, so GM isn't focusing on any particular area for its new hires. It's a similar story behind the hiring surge itself. GM said in its press release that the "second shift is necessary to meet forecasted market demand," a position Zemke reiterated. It's a matter of demand across the plant's portfolio, rather than any one particular product seriously outstripping supply. Naturally, the United Auto Workers is happy with the move. "The workforce at Detroit-Hamtramck is second to none," UAW Local 22 Shop Chairman Don LaForest said in the attached release. "We appreciate the opportunity to expand our UAW-GM family." Hiring is going on now, with the second shift slated to get underway in early 2016. GM's Detroit-Hamtramck Assembly to Add Second Shift and More Than 1,200 Jobs Plant will nearly double its workforce by early 2016 2015-10-22 DETROIT – General Motors is nearly doubling its workforce at Detroit-Hamtramck Assembly by adding a second shift and more than 1,200 hourly and salaried jobs. The addition of a second shift will increase the plant's workforce to approximately 2,800 people when hiring is completed. The second shift is necessary to meet forecasted market demand for the five cars produced at Detroit-Hamtramck. "This is the result of the award-winning vehicles Detroit-Hamtramck produces and the confidence GM has in our team to build world-class quality for our customers," said Plant Manager Gary West. Second shift hiring is underway, and the shift is scheduled to begin operations in early 2016. "The workforce at Detroit-Hamtramck is second to none," said UAW Local 22 Shop Chairman Don LaForest. "We appreciate the opportunity to expand our UAW-GM family." The 4.1 million-square-foot Detroit-Hamtramck Assembly opened in 1985. GM has invested $1 billion in the plant over the last six years, making it one of the company's most-agile manufacturing facilities in North America.