1988 Chevrolet Corvette Excellent Condition 60k Miles C4 Coupe 4 Speed Automatic on 2040-cars

Greeley, Colorado, United States

Body Type:Coupe

Vehicle Title:Clear

Engine:5.7 L

Fuel Type:Gasoline

For Sale By:Private Seller

Number of Cylinders: 8

Make: Chevrolet

Model: Corvette

Trim: Base

Options: Cassette Player, Leather Seats

Drive Type: 4 2peed Automatic

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Mileage: 60,080

Exterior Color: Cherry red

Interior Color: Black

Chevrolet Corvette for Sale

1970 chevrolet corvette ls5 coupe - low reserve - desirable ls5 "big block"

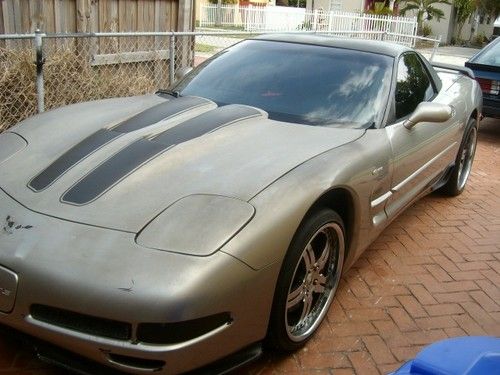

1970 chevrolet corvette ls5 coupe - low reserve - desirable ls5 "big block" 1999 corvette frc nice project

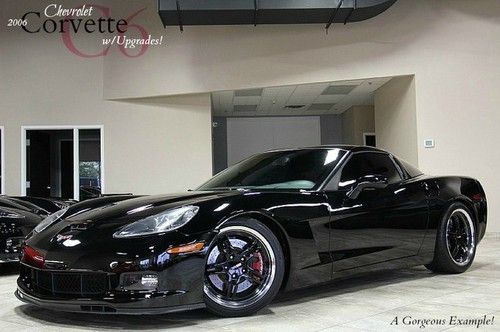

1999 corvette frc nice project 2006 chevrolet corvette coupe 6 speed 2lt z51 suspension performance upgrades $$(US $31,800.00)

2006 chevrolet corvette coupe 6 speed 2lt z51 suspension performance upgrades $$(US $31,800.00) 2007 corvette convertible 9330 miles red with tan interior(US $37,950.00)

2007 corvette convertible 9330 miles red with tan interior(US $37,950.00) 2005 chevrolet corvette coupe only 24k miles! 6 speed manual z51 suspension 1sb$(US $29,800.00)

2005 chevrolet corvette coupe only 24k miles! 6 speed manual z51 suspension 1sb$(US $29,800.00) 2001 corvette z06 with 612 original miles!

2001 corvette z06 with 612 original miles!

Auto Services in Colorado

Windsor Car Care ★★★★★

West Side Auto Body & Towing ★★★★★

Toyexus Service ★★★★★

Tito`s Cash for Cars ★★★★★

Suzuki-Mccloskey ★★★★★

Red Rock Auto Clinic ★★★★★

Auto blog

GM throttles back Chevy Malibu, Buick LaCrosse production over swollen inventories

Wed, 06 Feb 2013As inventory of the Chevrolet Malibu and Buick LaCrosse continues to pile up, General Motors will be idling its Fairfax Assembly Plant for two weeks, according to Automotive News. This move comes about a month after the plant was shut down for three weeks in late December and early January for the same reason. As of January 31, the GM had a 94-day supply of Malibu stock while the LaCrosse was a little worse with a 117-day supply.

Just last week, GM announced that it would be investing $600 million in upgrading this plant, but it's unclear what future plans the company has in store for Fairfax considering slow sales of both the plant's models. We do expect a refreshed and more luxurious LaCrosse shortly and an early design update for the Malibu to be announced at some point this year, although we have had no official word as to when either will happen.

Detroit 3 to implement delayed unified towing standards for 2015

Tue, Feb 11 2014Car buyers have a responsibility to be well-informed consumers. That's not always a very simple task, but some guidelines are self-evident. If you live in a very snowy climate, you generally know a Ford Mustang or Chevrolet Camaro might not be as viable a vehicle choice as an all-wheel drive Explorer or Traverse, for example. If you want a fuel-efficient car, it's generally a good idea to know the difference between a diesel and a hybrid. But what if it's kind of tough to be an informed consumer? What if the information you need is more difficult to come by, or worse, based on different standards for each vehicle? Well, in that case, you might be a truck shopper. For years, customers of light-duty pickups have had to suffer through different ratings of towing capacities for each brand. For 2015 model year trucks, though, that will no longer be a problem. According to Automotive News, General Motors, Ford and Chrysler Group have announced that starting with next year's models, a common standard will be used to measure towing capacity. The Detroit Three will join Toyota, which adopted the Society of Automotive Engineers' so-called SAE J2807 standards way back in 2011. The standard was originally supposed to be in place for MY2013, but concerns that it would lower the overall stated capacity for trucks led Detroit automakers to pass. Ford originally passed, claiming it'd wait until its new F-150 was launched to adopt the new standards, leading GM and Ram to follow suit. Nissan, meanwhile, has said it will adopt the new standards as its vehicles are updated, meaning the company's next-generation Titan should adhere to the same tow ratings as its competitors. While the adoption of SAE J2807 will be helpful for light-duty customers, those interested in bigger trucks will still be left with differing standards. There is no sign of the new tow standards being adopted for the heavy-duty market.

Sunday Drive: Performance comes in many shapes and sizes

Sun, Nov 19 2017The Chevrolet Corvette has always stood out as a bastion of reasonably priced performance, and the latest 'Vette has that in spades. And while its expected starting price of around $120,000 certainly isn't cheap, it's an undeniable deal in the supercar world – remember, this thing'll do 210 miles per hour thanks to its 755-horsepower supercharged V8 engine. And did you get a load of that massive rear wing? Team Corvette's longtime foe, the Porsche 911, is similarly hellbent on ultimate performance. And as a reminder of how long the Corvette/911 rivalry has been melting tires we present the 1990 Porsche 911 as reimagined by Singer you see below. It's beautiful, it's green, and it's packing 500 air-cooled horsepower. You don't have to burn gasoline to go fast, as proven by the second-generation Tesla Roadster, which was revealed as a surprise late last week. Elon Musk says it'll be the quickest car in the world with a 0-60 time of just 1.9 seconds. And while you may not think of a semi truck when you think speed, the Tesla Semi can do 0-60 in 5 seconds flat unloaded, or in 20 seconds with a load of 80,000 pounds. Compared to today's crop of diesel semis, that's amazing. Continuing the truck theme, we present an artists rendering of what the next-generation Ram 1500 pickup may look like. Spoiler alert: Ram's mini-semi look is giving way to something much more modern. There may even be a first-of-its-kind split tailgate at the rear. And if you don't think the Ram 1500 has anything to do with performance, we should remind you that it's one of the cheapest ways to get a tire-shredding Hemi V8 engine in America. 2019 Chevy Corvette ZR1: All hail the 755-horsepower C7 king This is the first Porsche 911 to get Singer and Williams' 500-horsepower engine Tesla Roadster surprise reveal | 'Quickest car in the world' Tesla Semi Truck revealed: Here are the key details This could be the next-generation 2019 Ram 1500 2019 Ram 1500 spotted with split tailgate