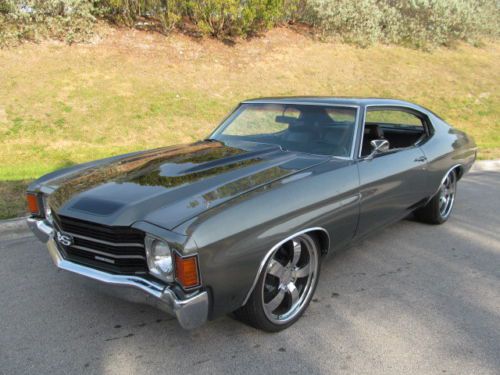

1972 Chevelle Restored Frame On on 2040-cars

North East, Maryland, United States

|

ALL PICTURES TAKEN MAY 2014 1972 CHEVELLE HIGH QUALITY DRIVER TILT STEERING WHEEL POWER STEERING POWER BRAKES

355 4 BOLT STRONG ENGINE WITH ALUMINUM HEADS. EDELBROCK ALUMINUM INTAKE HOLLEY CARB. FULL LENGHT HEADERS. ROLLER ROCKERS 350 TURBO TRANS SHIFT KIT 2200 STAHL 12 BOLT REAR 4:11 GEARS THE BODY AND PAINT ARE EXELLENT IT IS BEAUTIFUL,REALLY. LOOK AT PREP PICS. THIS CHEVELLE LOOKS AND RUNS AND SOUNDS GREAT IF YOU HAVE 5 0R LESS FEEDBACK CONTACT ME FIRST. I HAVE THE RIGHT TO CANCEL A BID. HAPPY BIDDING On Jun-02-14 at 13:36:03 PDT, seller added the following information: TIRE SIZE IS 245/60-15 ALL FOUR. DROVE IT 100 MILES PLUS OVER THE WEEK END.LOCAL CAR HANG OUTS WAS FUN. RUNS AND DRIVES GREAT. |

Chevrolet Chevelle for Sale

1968 chevelle 427 resto mod(US $41,500.00)

1968 chevelle 427 resto mod(US $41,500.00) 1970super sport convertable chevelle 12bolt/4spd

1970super sport convertable chevelle 12bolt/4spd 1972 chevelle ss clone - resto mod. / beautiful car(US $22,900.00)

1972 chevelle ss clone - resto mod. / beautiful car(US $22,900.00) 1973 chevelle malibu ss

1973 chevelle malibu ss 1970 chevelle ss !!! true super sport, muscle car, survivor, runs exellent !!!(US $22,500.00)

1970 chevelle ss !!! true super sport, muscle car, survivor, runs exellent !!!(US $22,500.00) 1965 chevelle convertible...350 engine...automatic(US $16,999.00)

1965 chevelle convertible...350 engine...automatic(US $16,999.00)

Auto Services in Maryland

Wiygul Automotive Clinic ★★★★★

Ware It`s At Custom Auto Refinishing ★★★★★

Vehicle Outfitter ★★★★★

Tire World ★★★★★

T & D Automotive Inc ★★★★★

S A Best Tires Inc ★★★★★

Auto blog

The Volt Dance had precedent; meet the Chevy Footlockers

Sun, Dec 14 2014Marketing in the auto industry can get weird sometimes – really quite bizarre, in fact. For example, remember the Chevy Volt dance from the 2009 Los Angles Auto Show? If not, a group boogied to a song about the electric car, and it was every bit as awkward (and hilarious) as that sounds. In fact, that innocent bit of promotion lives in infamy, as some pundits grabbed hold of it during General Motors' bailout and asked why America's tax dollars were going to such things. The Chicago Auto Show has been digging through its vault of vintage videos, and it has come up with something that might actually be worse than that Volt-themed routine. They're called the Chevy Footlockers, and they're a dance troupe somehow promoting the Cavalier at the 1988 Chicago show. The connection between the car and their routine is unclear, but it's gloriously cheesy in a Chippendales-meets-AC Slater sort of way. Also, there are props towards the end, but we aren't going to spoil them for you, because you just have to watch for yourself. As a bonus, there's another (brief) clip below showing a female dance group with the Geo Tracker at the '91 Chicago show, and they sing, too. Scroll down to watch both of these oddities. News Source: ChicagoAutoShow via YouTube [1], [2] Marketing/Advertising Chicago Auto Show Chevrolet GM Classics geo

Corvette owner finds stolen car, but can't get it back [w/video]

Wed, Feb 25 2015It's not too uncommon to hear about owners being reunited with their stolen cars decades after reporting them missing. The story of Terry Dietrich in Georgia starts that way with police finding her lost 1972 Chevrolet Corvette after over 40 years. However, this case takes a different turn because unless she wants to bid on it, Dietrich's likely not getting the 'Vette back. Just six months after purchasing it in 1972, Dietrich's blue Corvette was stolen in Georgia, and in 1975 the sports car found its way to a man in North Carolina. He kept the car right up until his death just a few months ago, and that's when restorer Gary Green bought the 'Vette from his widow, according to Yahoo Autos. Unfortunately, after acquiring the Corvette, Green found some major discrepancies. For one thing, the listed VIN pointed to a '69 convertible, and there was a different serial number on the frame. Green reported the problem to the local police, and they figured out it was the 'Vette Dietrich lost over four decades ago. Consequently, the cops impounded it. The issue now arises that while Dietrich is the victim of the theft, she isn't technically the car's last legal owner. After the Corvette was stolen, she reported the crime to her insurance company, and it paid on the claim, which essentially forfeited her ownership. To make matters slightly more confusing the company can't find the title on the 'Vette either, according to Yahoo Autos. That leaves the well preserved 'Vette sitting in a police impound lot. It will likely go to auction.

Steve McQueen's last movie car, now Pawn Stars-owned, up for auction [w/video]

Sun, 03 Feb 2013The last car Steve McQueen ever drove in a movie is officially up for auction. The 1951 Chevrolet Styline DeLuxe Convertible you see above is now owned by none other than Rick Harrison of Pawn Stars fame, but once ferried McQueen around the set of his last film, 1980's The Hunter. That flick saw the Bullit star play a bumbling bounty hunter and didn't exactly set the box office on fire. McQueen bought the car after production wrapped, and four years later it sold at his estate sale at the Imperial Palace in Las Vegas.

Flash forward to 2003, and the convertible received a full restoration back to near-stock specifications. Hagerty Insurance estimates the car to be worth around $45,000 without the significant providence. Given its ties to one of film's most popular gearheads, the old Chevrolet could fetch up to 10 times that when it goes under the gavel in Ft Luaderdale, Florida on March 22. You can head over to the Auctions America site for more information. You can also check out the trailer for The Hunter below.