1969 Chevrolet Chevelle V8 350 Automatic Bucket Seats Power Steering Wheels Look on 2040-cars

Irving, Texas, United States

Body Type:Coupe

Vehicle Title:Clear

Engine:V8

Fuel Type:Gasoline

For Sale By:Dealer

Number of Cylinders: 8

Make: Chevrolet

Model: Chevelle

Trim: Buckets Wheels Power Steering

Drive Type: RWD

Mileage: 57,859

Warranty: Vehicle does NOT have an existing warranty

Exterior Color: White

Number of Doors: 2

Interior Color: Black

Chevrolet Chevelle for Sale

Auto Services in Texas

Yang`s Auto Repair ★★★★★

Wilson Mobile Mechanic Service ★★★★★

Wichita Falls Ford ★★★★★

WHO BUYS JUNK CARS IN TEXOMALAND ★★★★★

Wash Me Down Mobile Detailing ★★★★★

Vara Chevrolet ★★★★★

Auto blog

Stolen '57 Chevy Returned To Owner After 30 Years

Fri, Feb 21 2014Three decades after it was stolen, a 1957 Chevrolet Bel Air has been returned to a Northern California man - in better shape than when he originally owned it. The Santa Rosa Press Democrat reports Ian "Skip" Wilson was shocked to get a call from the California Highway Patrol informing him that his long-lost Chevy was taken off an Australia-bound cargo ship. The 65-year-old says the car has had a lot of work done on it since it disappeared from his Lake County home in 1984. It was returned with a monogrammed interior, 17-inch racing wheels, rack-and-pinion steering and a 350-horsepower V-8 engine. The retired mechanic says the two-door was in sorry shape when he bought it for $375 in 1975 with plans for fixing it up. Related Gallery 2014 Chevrolet Corvette Stingray Test Drive View 9 Photos Weird Car News Chevrolet Safety

GM recalls 83,572 SUVs for ignition switch issue

Sun, Jan 4 2015General Motors is recalling 83,572 SUVs from the 2011 and 2012 model years over a potential ignition lock actuator issue. In affected vehicles, the actuator isn't the right size, which could cause the ignition to get stuck in the "Start" position, and then either due to a jarring event or a "cool interior temperature" the ignition could switch back to the "Accessory" position. Doing so would cause a loss of power assistance and the airbags might not deploy. This is a different ignition issue than the one that's been ongoing for the past year. GM said it expects that less than 500 vehicles suffer from the problem, but that the pool could include vehicles from 2007 through to 2014 that have already been fixed, but with defective parts. The 2011-2012 SUVs included in the National Highway Traffic Safety Administration notice: Cadillac Escalade, Escalade ESV, Escalade EXT, Chevrolet Avalanche, Silverado HD, Silverado LD, Suburban, Tahoe, GMC Sierra LD, Sierra HD, Yukon, and Yukon XL vehicles. GM will notify owners and dealers will inspect the ignition lock housing to see if it needs a free replacement. RECALL Subject : Ignition Lock Actuator may Bind Report Receipt Date: DEC 30, 2014 NHTSA Campaign Number: 14V827000 Component(s): ELECTRICAL SYSTEM Manufacturer: General Motors LLC SUMMARY: General Motors LLC (GM) is recalling certain model year 2011-2012 Cadillac Escalade, Escalade ESV, Escalade EXT, Chevrolet Avalanche, Silverado HD, Silverado LD, Suburban, Tahoe, GMC Sierra LD, Sierra HD, Yukon, and Yukon XL vehicles. In the affected vehicles, the ignition lock actuator may bind, making turning the key difficult or causing the ignition to get stuck in the "Start" position. CONSEQUENCE: If stuck in the "Start" position, the ignition may suddenly snap back into the "Accessory" position, causing a loss of engine, steering, and braking power, increasing the risk of a vehicle crash. If the vehicle is in a crash, the air bags may not deploy, increasing the risk of occupant injury. REMEDY: GM will notify owners, and dealers will inspect and replace the ignition lock housing, as necessary, free of charge. The manufacturer has not yet provided a notification schedule. Owners may contact GM customer service at 1-800-458-8006 (Cadillac), 1-800-222-1020 (Chevrolet), or 1-800-462-8782 (GMC). GM's number for this recall is 14696 for the original equipment, and 14912 for the service replacement parts.

Nissan Leaf sales double Chevy Volt to close out winning 2014

Mon, Jan 5 2015To close out the year, sales of the two most-popular plug-in vehicles in the US kept going in the direction that they had been all year. The Chevy Volt dropped and the Nissan Leaf had another record month. Sound familiar? The Volt sold 1,490 units in December, a year-to-year drop of 37.7 percent. For all of 2014, Volt sales were down 18.6 percent to just 18,805 (from 23,094 in 2013). On the Nissan side of the ledger, the Leaf sold 3,102 units, up 22.7 percent from the 2,529 sold in December 2013. For the year, Nissan sold 30,200 Leafs, up 33.6 percent from the 22,610 sold in 2013. A few other things to note: For every month in 2014, the Leaf sold more than it did for the same month in 2013. For the Volt, this was only true for three months (April, May and July). Funnily enough, the Volt sold exactly 1,478 units in both March 2013 and 2014. The Volt's 2014 total was lower than both 2013 and 2012, while the Leaf had its best year ever. There were three months in 2014 when people bought at least twice as many Leafs than bought a Volt (September, November, December). The Leaf outsold the Volt every month in 2014. The closest gap was 215 units, in February. The biggest was 1,612, in December. As you've most likely seen, GM is still busy teasing the new Volt, which will make its official debut at the Detroit Auto Show next week. We'll have a more in-depth green car sales post up soon. <iframe embedded="true" "="" scrolling="no" src="https://docs.google.com/spreadsheets/d/1oIuH75vaSHaaplD4x6gLsYjSsiN4oGmez1T63eaYdhY/pubhtml?widget=true&headers=false" height="430"> Nissan celebrates 30,000 leaf sales in 2014, best year ever for sales of any plug-in vehicle NASHVILLE, Tenn. (Jan. 5, 2015) – Nissan, the world leader in electric vehicle sales, shattered yet another sales record with 30,200 LEAF vehicles sold in 2014, which is the first time any plug-in has sold more than 30,000 units in a single year. "Now in its fifth model year, Nissan LEAF is more popular than ever and continues to bring new buyers to Nissan," said Brendan Jones, director, Nissan Electric Vehicle Sales and Infrastructure. "From the beginning our vision was to bring electric vehicles to the mass market in a practical and fun-to-drive package, which is what makes Nissan LEAF the best-selling electric car in the world." Last month, Nissan sold 3,102 all-electric LEAFs, up 22.7 percent from the prior year and a December record.

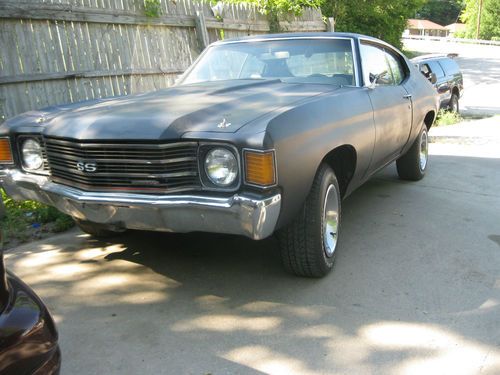

1972 chevrolet chevelle base hardtop 2-door 5.0l

1972 chevrolet chevelle base hardtop 2-door 5.0l 1970 chevelle malibu

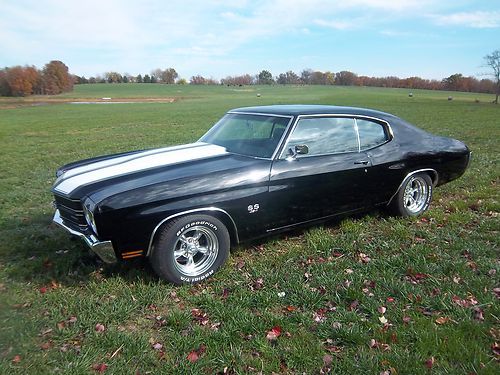

1970 chevelle malibu 1967 67 chevy chevelle 300 custom two door sedan post 283 powerglide low miles

1967 67 chevy chevelle 300 custom two door sedan post 283 powerglide low miles 1970 chevelle ss

1970 chevelle ss 1965 chevelle malibu

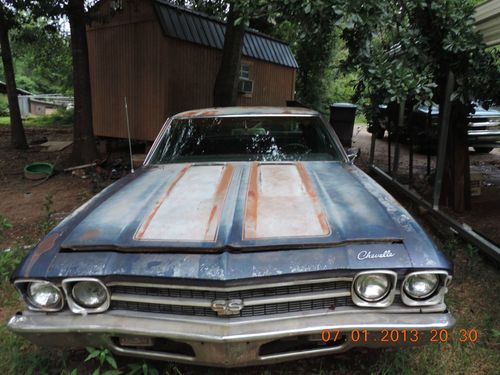

1965 chevelle malibu 1969 chevrolet chevelle ss hardtop 2-door 6.5l

1969 chevrolet chevelle ss hardtop 2-door 6.5l