2014 Chevrolet Silverado 1500 on 2040-cars

4500 Raeford Rd, Fayetteville, North Carolina, United States

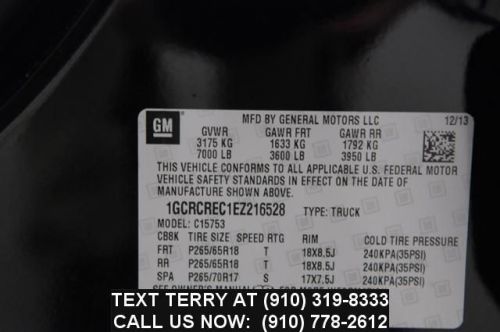

VIN (Vehicle Identification Number): 1GCRCREC1EZ216528

Stock Num: 1429181

Make: Chevrolet

Model: Silverado 1500

Year: 2014

Exterior Color: Black

Interior Color: Jet Black

Options: Drive Type: RWD

Number of Doors: 4 Doors

Mileage: 243

Price excludes tax, tag, and doc fee. Special financing may be available in lieu of certain rebates. Advertised price includes the following rebates: $750 - USAA Private Offer. . Customer must be able to obtain a USAA membership letter or proof of existing USAA auto insurance. See dealer for details., $3,250 - General Motors Consumer Cash Program. Exp. 06/30 Please print this vehicle information and callfor your internet discount $______ and code _____Please get coordinators signature upon arrival:_____________________

Chevrolet Silverado 1500 for Sale

2014 chevrolet silverado 1500(US $34,012.00)

2014 chevrolet silverado 1500(US $34,012.00) 2014 chevrolet silverado 1500(US $47,582.00)

2014 chevrolet silverado 1500(US $47,582.00) 2014 chevrolet silverado 1500(US $24,928.00)

2014 chevrolet silverado 1500(US $24,928.00) 2014 chevrolet silverado 1500(US $24,988.00)

2014 chevrolet silverado 1500(US $24,988.00) 2014 chevrolet silverado 1500(US $31,730.00)

2014 chevrolet silverado 1500(US $31,730.00) 2014 chevrolet silverado 1500(US $33,661.00)

2014 chevrolet silverado 1500(US $33,661.00)

Auto Services in North Carolina

Walkertown Tire Service ★★★★★

Victory Tire & Auto Svc ★★★★★

Valvoline Instant Oil Change ★★★★★

USA Paint & Body ★★★★★

Truth Automotive-Transmission ★★★★★

Triangle Window Tinting ★★★★★

Auto blog

GM struggles to sell small cars, plans to lay off 2,084 employees at two plants

Thu, Nov 10 2016Due to low demand for some of its vehicles, General Motors plans to cut 2,084 jobs at its assembly plants in Lordstown, OH and Lansing, MI. At the same time, the automaker also announced plans to invest approximately $900 million in three of its facilities – the Toledo Transmission Operations in Ohio, Bedford Casting Operations in Indiana, and Lansing Grand River in Michigan - for future products. GM will discontinue the third shift at both the Lansing Grand River plant and the Lordstown, OH plant. The Cadillac ATS, Cadillac CTS, and Chevrolet Camaro are made at the automaker's plant in Michigan, which currently has 2,700 employees. The move to eliminate the third shift affects 810 hourly workers, as well as 29 salaried employees, starting on January 16th. The plant in Lordstown, OH currently has 4,500 employees and makes the Chevrolet Cruze sedan. The plan to discontinue the third shift will affect 43 salaried workers and 1,202 hourly employees and will start on January 23rd. As Fortune points out, sales of the Cruze are down 20 percent through October, while sales of the Cadillac ATS and CTS were down 17 percent through the same period of time. In addition to cutting the third shift at both assembly plants, the automaker plans to invest a total of $900 million between three of its facilities for unnamed future products. GM's Toledo Transmission Operations will receive $667.6 million, the Lansing Grand River Assembly plant will receive $211 million, and the automaker's Bedford Casting Operations will get $37 million. Last year, GM cut roughly 500 jobs from its Orion Township factory due to slow sales of the Chevrolet Sonic and Buick Verano, with surging crossover and SUV sales as the most likely culprit. With GM posting much healthier sales figures for the Chevrolet Equinox and Cadillac XT5 compared to the ATS, CTS, and Cruze, it looks like compact SUVs are to blame for this year's layoffs as well. Related Video: News Source: Fortune, General MotorsImage Credit: REUTERS / Rebecca Cook Hirings/Firings/Layoffs Plants/Manufacturing Cadillac Chevrolet GM Coupe Sedan Lordstown Ohio

Meet the mother-daughter team that's worked on almost every Chevy Volt

Sun, May 11 2014It's Mother's Day, and we're soft enough we love our mothers enough to share a new video from General Motors with you. In it, we meet Monique Watson (left) and Evetta Osbourne, a mother-daughter team that works at the Detroit-Hamtramck Assembly where GM makes the Chevy Volt (along with all of GM's other plug-in hybrids: the Opel Ampera, Holden Volt and Cadillac ELR). The two work side-by-side and have installed the lithium-ion battery pack on almost all of those vehicles - nearly 80,000 of them - since GM started making the pre-production Volts in 2009. In a prepared statement, Watson said that she likes working next to her mom, day in and day out, and they the two are totally in sync when it comes to putting the 400-pound, 16.5-kWh packs into the vehicle undersides. They two can also share stories throughout the day, and Watson said, "The arrangement has absolutely improved our relationship." Osborne started working at Detroit-Hamtramck in 1999, Watson since 2006. If you're driving a Volt today, you probably have them to thank for doing a bit of the work putting your car together. See a short video of them in action below. It's Always Mother's Day for Detroit-Hamtramck Duo Mother, daughter install lithium-ion battery pack in nearly all GM electric vehicles 2014-05-08 DETROIT – For Detroit resident Evetta Osborne, every day is Mother's Day. That's because she literally works side by side with her daughter, Monique Watson, at General Motors' Detroit-Hamtramck assembly plant. They have installed the lithium-ion battery pack on nearly every Chevrolet Volt, Opel Ampera, Holden Volt, and Cadillac ELR since production began. In fact, apart from vacation days and an occasional sick day, the mother-daughter duo has installed almost every battery pack since the Volt was in pre-production in 2009. The ELR launched earlier this year. All told – including Ampera – that's more than 80,000 electric vehicles. "We're a good team and our relationship is secondary when it comes to performing our jobs – but it's great to work alongside my daughter, said Osborne, a mother of five. Because the battery packs weigh more than 400 pounds each, automatic guided vehicles – robotic carts that use sensors to follow a path through the plant – deliver them just as the vehicle body structures glide into position overhead. The carts then lift the T-shaped packs, and Osborne and Watson guide them into the chassis and secure each one with 24 fasteners.

GM patent reveals new two-stage turbocharger

Fri, Jun 24 2016Modern turbochargers may be some of the best ever made, but performance is something that engineers are always trying to improve. According to GM Inside News, General Motors (GM) is hoping to alleviate some of the negative aspects of a two-stage turbocharger setup with a newly-patented design. The patent, that was filed on May 19, 2016, reveals a clever bypass system that allows the engine, a four-cylinder unit, to optimize both the low-pressure and high-pressure inlets for its respective functions. According to the filing, a conventional two-stage turbocharger setup is engineered to allow both turbines to operate simultaneously at low and mid engine speeds. At high engine speeds, only the low-pressure turbine works. The setup can't isolate either the low or high pressure side, which can impair low-end performance. GM's new two-stage turbocharger setup looks to eliminate this by linking the high-pressure turbo to the exhaust manifold through the high-pressure inlet duct. The low-pressure turbo is attached to the high-pressure turbo by a low-pressure inlet duct, which is linked to a connecting channel. A single actuator that is housed in the exhaust manifold creates a bypass that can opens the high-pressure inlet or close the connecting channel. Depending on what the engine load and speed is, the ECU guides the actuator—a single rotating spindle with discs corresponding to flanges on the high and low pressure sides—to isolate one of the two turbos. Isolating the turbos allow the respective inlets to be engineered for the best possible fluid dynamic performance. The setup should increase performance and decrease lag. There's no word on what car this setup will make an appearance on, but it will most likely be used in premium vehicles before trickling down to the rest of GM's vehicles. Related Video: News Source: GM Inside News, AutoGuide via GM Authority Cadillac Chevrolet GM Technology Sedan turbo patent engine turbocharging