C5 Z06 Great Condition on 2040-cars

Tampa, Florida, United States

Selling this beauty with low miles. Second owner. I have all invoices and maintenance history. Worth seeing.

Chevrolet Corvette for Sale

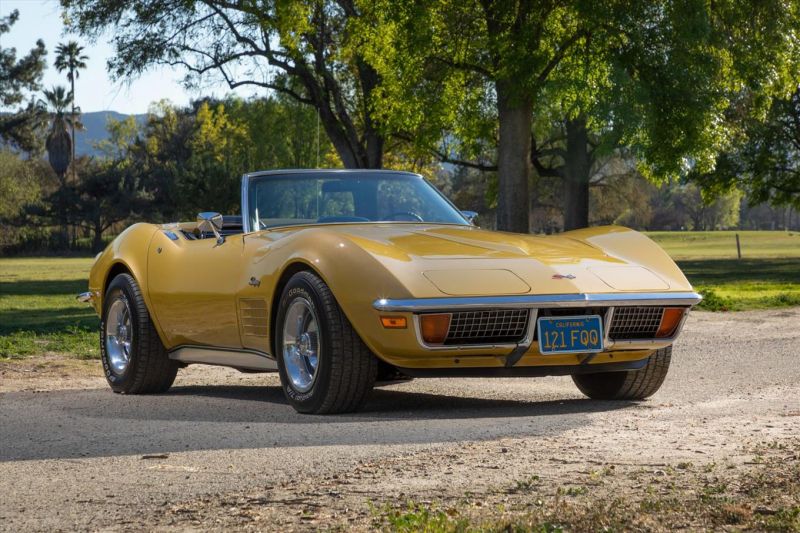

1972 chevrolet corvette convertible 4-speed(US $22,600.00)

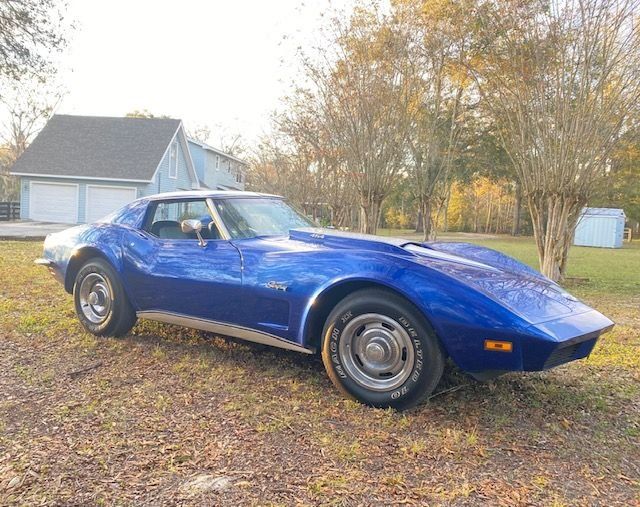

1972 chevrolet corvette convertible 4-speed(US $22,600.00) 1973 corvette stingray(US $8,690.00)

1973 corvette stingray(US $8,690.00) 1973 corvette, 86k miles(US $7,500.00)

1973 corvette, 86k miles(US $7,500.00) 1973 c3 stingray - clean title(US $8,200.00)

1973 c3 stingray - clean title(US $8,200.00) 1963 chevrolet corvette split-window coupe 4-speed(US $28,200.00)

1963 chevrolet corvette split-window coupe 4-speed(US $28,200.00) 1978 chevrolet corvette pace car edition l82 4-speed(US $33,500.00)

1978 chevrolet corvette pace car edition l82 4-speed(US $33,500.00)

Auto Services in Florida

Y & F Auto Repair Specialists ★★★★★

X-quisite Auto Refinishing ★★★★★

Wilt Engine Services ★★★★★

White Ford Company Inc ★★★★★

Wheels R US ★★★★★

Volkswagen Service By Full Throttle ★★★★★

Auto blog

Why Cadillac thinks it needs to succeed in Europe to sell cars elsewhere

Tue, 26 Feb 2013Ward's Auto has taken an interesting look at the renewed focus General Motors is showing towards Cadillac in Europe. Susan Docherty, president and managing director of Chevrolet and Cadillac in Europe (pictured), says in order for the luxury brand to thrive in China, it first needs to succeed in the old country. The reason? Chinese buyers look to Europe for cues as to what's deemed worthy of the term "luxury." There are hurdles to the plan, however. In addition to the fact that the EU is flooded with high-end nameplates, GM doesn't necessarily have the distribution network in place to put buyers behind the wheel.

Combine that with persistent economic woes and Cadillac's checkered past marred by a lack of diesel engine options and a bankrupt distributor, and the road ahead for the brand looks like less of an uphill climb and more like a straight-up cliff face. But Docherty is optimistic and says she has a plan for the brand. We recommend heading over to Ward's for a closer look at the full read.

Autotrader picks best cars for 2015's college grads

Sun, May 31 2015Summer is here and the school season is winding to a close. That means millions of students will be graduating college and (hopefully) entering the workforce. For many, that will mean buying a new car suited to the new stage in life into which they will now be embarking. That can be a bewildering choice, especially for someone who's never bought a car before. Fortunately, Autotrader has come up with a short list of recommended cars Ė new and used ¬Ė which it recommends to the graduating class of 2015. Among the site's top choices are some compelling crossovers and hatchbacks, including the Buick Encore, Chevy Trax, and Jeep Renegade, as well as the Honda Fit, Nissan Versa Note, Mazda3 and Fiat 500. Can't stretch to buying new, or don't see the point? Autotrader has also identified the Toyota Camry, Ford Fusion and even the Lexus IS as smart buys in the certified pre-owned category. "Any time someone goes through a major life change, such as graduating college, they need to determine if their current ride makes sense for their lifestyle, from both a financial and functional perspective," says Autotrader editor Brian Moody. "For example, while that hand-me-down SUV from your parents was nice when you turned 16, you may want to opt for a safer, more fuel-efficient car as you transition into the working world." Autotrader Names 10 Best Cars for Recent College Graduates ATLANTA, May 28, 2015 /PRNewswire/ -- For many, graduating college is a milestone like no other ¬Ė it represents a new chapter, a proud accomplishment and, fortunately or unfortunately, financial independence. Luckily for graduates who are in the market for a new car to suit their post-college lifestyle, Autotrader's expert editors say now is a great time to make a purchase, as dealerships are flush with affordable models that are fun, fuel-efficient and thoughtfully designed. Autotrader Logo "Any time someone goes through a major life change, such as graduating college, they need to determine if their current ride makes sense for their lifestyle, from both a financial and functional perspective," said Brian Moody, site editor for Autotrader.

Best 3rd row SUVs of 2022

Wed, Oct 19 2022If you plan on using a vehicle's third row a lot, let us at least make the suggestion that a minivan would be a smarter bet than anything you're going to see on this list of best three-row SUVs. Their third rows are bigger, more comfortable and easier to get to. The kids will definitely be happier. Here are our two top choices.  OK, now that that's out of the way, we totally get why minivans are totally depressing and that if the kids want to be happier, they can buy their own darn vehicle. You're buying, you're driving, you're being seen in it and you'd rather have a three-row SUV. Fair enough. Luckily, there are more choices than ever and they're really good. The best do a particularly good job of being family friendly without looking like a drab transportation appliance, although really, you can't go wrong with any of the mainstream three-row SUVs. Now, some of the luxury choices are a bit suspect, including those that are otherwise very appealing but have cramped third-row seats (the Genesis GV80 comes to mind). We're focusing on three-row SUVs here, so having a usable third row is a must.   In this list, we have broken things down into four sub-categories: Best Three-Row Crossover |  Best Full-size Three-Row SUV Best Luxury Three-Row SUV |  Best Flagship Luxury Three-Row SUV Note that we define crossovers as SUVs since most buyers use the terms interchangeably, but acknowledge that "crossover" is literally a vehicle with a car-like unibody structure as opposed to the truck-like, body-on-frame construction that traditionally has defined "SUV." In other words, we consider all crossovers SUVs, but not all SUVs are crossovers (specifically those in the full-size segment and some in the flagship luxury segment). Best Three-Row Crossover SUVs of 2024 2024 Honda Pilot Why it stands out: Exceptional storage and cargo space; unique second-row functionality; refined ride; versatile and capable TrailSport; advanced AWDCould be better: Subpar acceleration with lackadaisical transmission and engine response; so-so driver assistance tech Read our full 2024 Honda Pilot Review The Honda Pilot was completely redesigned for 2023. It maintains its predecessor's family friendly packaging and overall focus, but it has injected a welcome sense of style (especially in the TrailSport pictured above) that makes it stand out much better from the big crossover crowd.