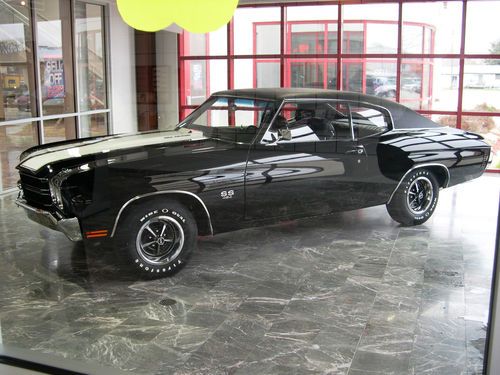

1971 Chevelle Project Car on 2040-cars

Fleetwood, Pennsylvania, United States

Fuel Type:Gasoline

Engine:None

For Sale By:Private Seller

Mileage: 63,191

Make: Chevrolet

Warranty: Vehicle does NOT have an existing warranty

Model: Chevelle

Trim: None

Drive Type: None

This Is A 1971 Chevelle Project Car (Rolling Body--No Motor Or Transmission)The Floor Boards In The Trunk Were Replaced. It Has The Hump For The Automatic Transmission On The Floor. New Quarter Skins Were Tack Welded On (Welds Needs To Be Completed). I Also Am Including A Good Rear Seat. The Came Originally Equipped With Front Disk Brakes Power Steering. It Has The SS Front Fenders. The Frame Is In Good Condition. Parts That I Know Are New--Front And Rear Big Block Coil Springs And The Front Dash Pad. It Has A 10 Bolt Rear. As You Can See In The Pictures There Are Extra Parts In The Trunk That Go With The Car. The Front Windshield Needs To Be Replaced, The Rest Of The Glass On The Car Is Ok. There Was A Patch Panel Installed On Passenger Side Firewall, It Came With That. This Car Has A lot Of Potential, I Just Do Not Have The Time To Complete It. This Is A Total Project Car And Needs Total Restoration. Any Questions Please Email Me. Buyer Is Totally Responsible For Pickup And Transfer Of Car And Title. Title Is Clear And In My Name. Serious Bidders Only, Please.

Chevrolet Chevelle for Sale

Auto Services in Pennsylvania

Wright`s Garage ★★★★★

Williams, Roy ★★★★★

West Tenth Auto ★★★★★

West Industrial Tire ★★★★★

United Imports Inc ★★★★★

Toms Auto Works ★★★★★

Auto blog

EcoCar2 is on the hunt for a better, cleaner Chevy Malibu [w/video]

Thu, Jun 12 2014The students spent three years transforming an ordinary Chevy Malibu into a revolutionary vehicle. Not far from the building where General Motors once invented the Chevy Volt, a dozen or so college students are standing on the blacktop alongside a test track, watching a professional driver push the limits of a plug-in hybrid car they've built that's far more radical. These students, from Colorado State University, have spent the past three years transforming an ordinary Chevy Malibu into a revolutionary vehicle. At first glance, it still looks like a regular sedan. But under the hood, they've installed a hybrid powertrain that contains both hydrogen and electric power sources. Even by the standards of the Department of Energy competition they're participating in, it's an outlier. That's exactly what they had in mind. "We didn't want to come here and tell them how to build a better Volt," said Tom Bradley, faculty adviser for the Colorado State team. "They already know how to do that. We can tell them how to think about these possibilities in a whole new way." After three years of work, it all comes down to this. The Colorado State team was one of 15 that came to GM's Milford Proving Grounds last week for the final stretch of the EcoCar2 competition, which challenges regular college students who have no automotive experience to do nothing less than reinvent the American car. The teams have come from across North America, and include schools like Ohio State and Virginia Tech that have a long history of participating in similar competitions, and schools like the University of Washington and Embry-Riddle Aeronautical University that are here for the first time. After three years of work, it all comes down to this. The teams have operated 24 hours a day for almost two weeks here at the Proving Grounds, running a gamut of tests that include a 310-point safety inspection, emissions and energy-consumption tests and road tests, in which professional GM drivers ensure they're road worthy. The winning team will be announced tonight in Washington D.C. Revolutionary cars, ordinary package While other green-car competitions encourage extreme designs, this one comes with a somewhat constraining twist: Yes, students must improve fuel economy and reduce emissions, but in the end, they still have to have a car that would appeal to mainstream customers. In practical terms, that means they must keep conveniences like air conditioning and trunk space.

Experimental mid-engine XP-819 Corvette going up for auction

Sun, 17 Feb 2013It seems to be commonplace that when a new Corvette is in development, rumors swirl about a possible mid-engine layout. As is the case of Chevy's most recent C7 Corvette, these rumors never pan out.

In any case, the idea for a 'Vette with an engine mounted behind the driver can probably all be traced back to a single car, the 1964 XP-819 prototype. Built as an "engineering exercise" back in 1964, the prototype was designed with a rear-mounted engine. History tells us that the idea of a rear-engine Corvette fizzled, and the XP-819 was eventually cut up into pieces and stored at a shop in Daytona Beach, FL.

After sitting for untold years, a restoration project started on the car, and while it isn't yet fully completed, the current owner of the car, Mid America Motorworks, will have the car on display at the 2013 Amelia Island Concours d'Elegance as a "driveable chassis" with hopes of having a fully completed car ready to bring to next year's show.

Meet the mother-daughter team that's worked on almost every Chevy Volt

Sun, May 11 2014It's Mother's Day, and we're soft enough we love our mothers enough to share a new video from General Motors with you. In it, we meet Monique Watson (left) and Evetta Osbourne, a mother-daughter team that works at the Detroit-Hamtramck Assembly where GM makes the Chevy Volt (along with all of GM's other plug-in hybrids: the Opel Ampera, Holden Volt and Cadillac ELR). The two work side-by-side and have installed the lithium-ion battery pack on almost all of those vehicles - nearly 80,000 of them - since GM started making the pre-production Volts in 2009. In a prepared statement, Watson said that she likes working next to her mom, day in and day out, and they the two are totally in sync when it comes to putting the 400-pound, 16.5-kWh packs into the vehicle undersides. They two can also share stories throughout the day, and Watson said, "The arrangement has absolutely improved our relationship." Osborne started working at Detroit-Hamtramck in 1999, Watson since 2006. If you're driving a Volt today, you probably have them to thank for doing a bit of the work putting your car together. See a short video of them in action below. It's Always Mother's Day for Detroit-Hamtramck Duo Mother, daughter install lithium-ion battery pack in nearly all GM electric vehicles 2014-05-08 DETROIT – For Detroit resident Evetta Osborne, every day is Mother's Day. That's because she literally works side by side with her daughter, Monique Watson, at General Motors' Detroit-Hamtramck assembly plant. They have installed the lithium-ion battery pack on nearly every Chevrolet Volt, Opel Ampera, Holden Volt, and Cadillac ELR since production began. In fact, apart from vacation days and an occasional sick day, the mother-daughter duo has installed almost every battery pack since the Volt was in pre-production in 2009. The ELR launched earlier this year. All told – including Ampera – that's more than 80,000 electric vehicles. "We're a good team and our relationship is secondary when it comes to performing our jobs – but it's great to work alongside my daughter, said Osborne, a mother of five. Because the battery packs weigh more than 400 pounds each, automatic guided vehicles – robotic carts that use sensors to follow a path through the plant – deliver them just as the vehicle body structures glide into position overhead. The carts then lift the T-shaped packs, and Osborne and Watson guide them into the chassis and secure each one with 24 fasteners.

1969 chevelle ss 396 4 speed no reserve all #'s matching survivor barn find

1969 chevelle ss 396 4 speed no reserve all #'s matching survivor barn find 1972 chevelle ss

1972 chevelle ss 1968 chevrolet chevelle ss convertible 2-door 6.5l

1968 chevrolet chevelle ss convertible 2-door 6.5l 1965 chevelle super sport

1965 chevelle super sport 1971 chevrolet chevelle malibu sports coupe (ss clone)

1971 chevrolet chevelle malibu sports coupe (ss clone) 1970 chevrolet chevelle ss 454

1970 chevrolet chevelle ss 454