1965 Chevrolet Chevelle on 2040-cars

Cub Run, Kentucky, United States

ENGINE- LS3 pullout from a 2014 Camaro SS. Had 62k miles when bought. Now has 73k miles. All engine mods were

installed at 64k miles- Made 453 rwhp and 416 rwtq- Livernois stage 2 cam package. 230 intake duration with .590”

lift and 236 exhaust duration with .600” lift. 114 LSA- Livernois stage 2 heads package. 5 axis cnc machined,

custom ground valves, dual valve springs, Ti retainers.- Yella Terra pedestal shaft rockers- ARP head bolts- New GM

timing chain and oil pump- ATI crankshaft dampener 918628- Holley orange tall valve covers- Armando’s racing

custum built 9 qt oil pan with remote filter kit.- BP automotive stand alone wiring harness with stock tuned

computer- Mighty Mouse oil catch can- K&N air filter- Accel porcelain spark plug wires

DRIVETRAIN- Tremec TR6060 pullout from 2014 Camaro SS. Sent off to Promotion Powertrain for upgraded synchros,

pads, and seals. Good for 700 lb ft.- MGW shifter- Monster LT1-S twin disc clutch- new GM slave cylinder and

throwout bearing with upgraded billet bearing support.- 3” Aluminum CV joint driveshaft- Moser 12 bolt axle with

tapered roller axle bearings.- 33 spline axles- 3.73 gears with Detroit Tru Trac LSD- Aluminum girdle cover

SUSPENSION- All UMI components. Mixture of stage 3.5 and stage 5- Adjustable tubular front upper contol arms with

tall ball joints- Tubular front lower control arms with delrin bushings- Adjustable tubular rear upper and lower

control arms with roto heim joints- Spectacular UMI monotube shocks- Rear LCA braces- Bumpsteer kit- 1” lowering

springs- 1 1/4” solid front sway bar, 1” adjustable pro touring rear sway bar.

BRAKES- Front Wilwood 14” Aerolite 6R road race. 6 piston floating rotors.- Rear Wilwood 12” Dynalite 4 piston

brake kit.- Wilwood master cylinder- dual 8” booster- Wilwood proportioning valve

EXHAUST- Doug Thorley mid length ceramic coated headers- 3” exhaust with x-pipe- Holley Flowtech Warlock mufflers

FUEL SYSTEM- Aeromotive stealth gen 2 tank setup 18417. 340 lph pump- Aeromotive 13109 fuel psi regulator- -6 an

hard lines with 10 micron servicable filter.

INTERIOR- Sparco R333 adjustable race seats up front. Reupholsterd rear seat and sail panel- Sparco steering wheel-

Classic Instruments electronic autocross gauge set. Gauges for tach/speedo/fuel level(fuel level not working at the

moment)/oil psi/coolant temp/battery/oil temp/fuel psi- Custom removable harness bar with Takata harness- Added

support plates for 3 point seat belts in front- Floor pans in great shape. Coated pans and installed Dynamat. New

carpet kit installed

WHEELS AND TIRES- TSW Nurburgring 18x9 rotary forged- 275/35r18 Continental extreme sport- new tires on front

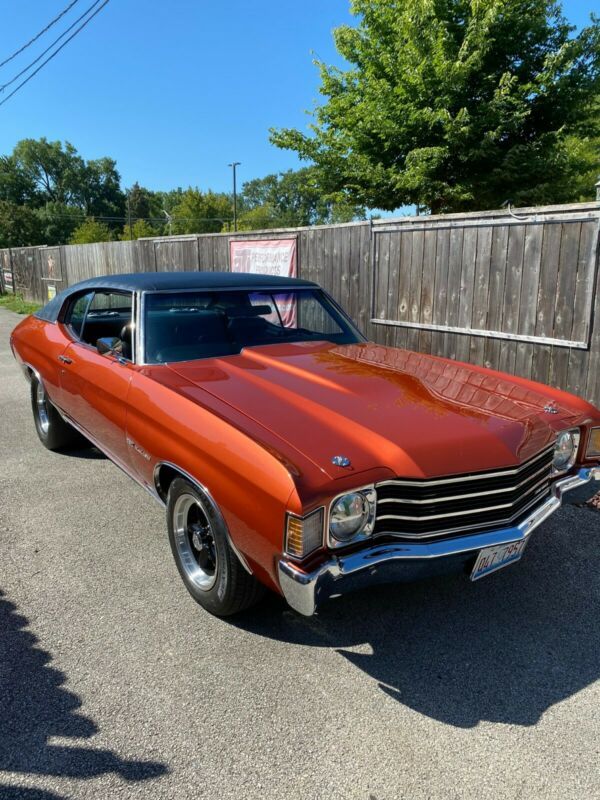

BODY PANELS- All original. At some point in the cars life it has been hit in the drivers quarter panel. You can see

the paint quality in the pics. It’s definitely not a show car but it has the survivor look. There are two very

small places of rust showing on the passenger side behind the front and rear wheel.

Chevrolet Chevelle for Sale

1969 chevrolet chevelle ss super sport(US $17,500.00)

1969 chevrolet chevelle ss super sport(US $17,500.00) 1968 chevrolet chevelle ss ss(US $17,500.00)

1968 chevrolet chevelle ss ss(US $17,500.00) 1972 chevrolet chevelle(US $14,350.00)

1972 chevrolet chevelle(US $14,350.00) 1972 chevrolet chevelle malibu ss(US $22,540.00)

1972 chevrolet chevelle malibu ss(US $22,540.00) 1972 chevrolet chevelle big block 454(US $18,060.00)

1972 chevrolet chevelle big block 454(US $18,060.00) 1972 chevrolet chevelle(US $16,170.00)

1972 chevrolet chevelle(US $16,170.00)

Auto Services in Kentucky

Wathen`s Service Center ★★★★★

Tri-State Auto Outlet ★★★★★

Tire Discounters ★★★★★

Tim Frye`s Auto Repair ★★★★★

Taylor County Muffler Shop ★★★★★

South Broadway Collision Center ★★★★★

Auto blog

Weekly Recap: GM plans massive new paint shop at Chevy Corvette factory

Sat, May 23 2015General Motors is laying out some serious green to maintain the Chevy Corvette's expansive color palette. The automaker is breaking ground on a new paint shop this summer that's part of a $439-million investment to upgrade the 34-year-old Bowling Green, KY, factory that builds the Stingray. The massive new structure will total 450,000 square feet, nearly half the size of the current 1-million square-foot facility. Construction is expected to take two years and won't impact Corvette production. The upgrades include new robots that save paint and create a better finish, longer, more efficient ovens to bake in the finish, and LED lighting. There's also a dry scrubbing booth technology with a limestone handling system that eliminates waste. GM has invested $135 million in the factory in last four years for the changeover to build the C7 and to relocate its Performance Build Center to Bowling Green. The improvements continue to modernize the Kentucky factory, which has become a tourist attraction in its own right, as more than 56,000 enthusiasts visited it last year. The upgrades are part of a $5.4-billion investment GM confirmed in April that will remake its US footprint in the next three years. The Bowling Green expansion underscores GM's continued commitment to the Corvette, which sold nearly 38,000 copies around the world last year, an eight-year high. "With this major technology investment, we can continue to exceed the expectations of sports car buyers for years to come," North American manufacturing manager Arvin Jones said in a statement. OTHER NEWS & NOTES Takata recall hits 34 million vehicles The National Highway Traffic Safety Administration expanded the Takata airbag recall to an almost unthinkable 34 million vehicles on Tuesday. The recall is part of an agreement reached by the two sides where Takata admitted some of its airbag inflators have a defect, and the deal compels the company to comply with all future regulatory actions and investigations. Takata's airbag inflators were produced with "a propellant that can degrade over time" and lead to ruptures, NHTSA said. Six deaths have been attributed to the flaw worldwide. Investigations conducted by Takata, automakers, and others have not determined the exact cause of the inflator problem, but NHTSA said moisture appears to alter the propellant's chemical structure. It then ignites too rapidly, creates too much pressure that ruptures the inflator, and blasts shards of metal at passengers.

2016 Chevy Malibu exhaustively tested with four decades of data

Fri, Mar 13 2015Chevy is preparing to unveil its new Malibu sedan at the upcoming New York Auto Show next month. But when it does, it's not like it will have appeared overnight. The development of any new vehicle – especially one as widely produced by a major automaker as the Malibu – involves rigorous and relentlessly punishing tests. In the Malibu's case, that meant 1.5 million miles of driving from the scorching heat of Arizona in July to the frigid cold of northern Canada in January and everything in between. The Bowtie brand also says it incorporated four decades' worth of data taken from vehicles driving in locations around the world since 1972 in order to make the Malibu the best it could be. We'll have to wait to find out the results of all that exhaustive testing, but you can catch a sneak peek at the new sedan in the video above. Four Decades of Data Used to Test 2016 Chevrolet Malibu Recorded customer use drives durability testing for next-generation midsize sedan 2015-03-11 DETROIT – Data collected over decades from across the globe is helping ensure the 2016 Chevrolet Malibu can handle the world's worst roads even if the all-new midsize sedan never drives on them. Data collection boxes are placed in cars in real-world driving conditions around the world. Since 1972, these devices have accurately recorded the harshness and frequency of every jounce, bump and shudder inflicted on the car on roads in the U.S., Russia, Saudi Arabia and developing markets. "Although most Malibu owners will never put their car through similar abuse, we test all new vehicles in extreme climates, inclement weather and on punishing road surfaces," said Dan Devine, Malibu validation engineer. "The 2016 Malibu is definitely up to these challenges." Tests like these ensured the current generation Malibu was dependable and durable, two qualities that in turn helped Malibu stand out from its rivals in important quality surveys, such as J.D. Power's Initial Quality Study and Vehicle Dependability Study. General Motors engineers analyze the data to calculate the precise amount of damage potholes and other hazards create over 150,000 miles. Then the conditions are replicated at GM's Milford Proving Ground in Michigan on three unique road courses, each riddled with simulated potholes of increasing severity. Engineers run preproduction cars through the course up to hundreds of times.

GM patent reveals new two-stage turbocharger

Fri, Jun 24 2016Modern turbochargers may be some of the best ever made, but performance is something that engineers are always trying to improve. According to GM Inside News, General Motors (GM) is hoping to alleviate some of the negative aspects of a two-stage turbocharger setup with a newly-patented design. The patent, that was filed on May 19, 2016, reveals a clever bypass system that allows the engine, a four-cylinder unit, to optimize both the low-pressure and high-pressure inlets for its respective functions. According to the filing, a conventional two-stage turbocharger setup is engineered to allow both turbines to operate simultaneously at low and mid engine speeds. At high engine speeds, only the low-pressure turbine works. The setup can't isolate either the low or high pressure side, which can impair low-end performance. GM's new two-stage turbocharger setup looks to eliminate this by linking the high-pressure turbo to the exhaust manifold through the high-pressure inlet duct. The low-pressure turbo is attached to the high-pressure turbo by a low-pressure inlet duct, which is linked to a connecting channel. A single actuator that is housed in the exhaust manifold creates a bypass that can opens the high-pressure inlet or close the connecting channel. Depending on what the engine load and speed is, the ECU guides the actuator—a single rotating spindle with discs corresponding to flanges on the high and low pressure sides—to isolate one of the two turbos. Isolating the turbos allow the respective inlets to be engineered for the best possible fluid dynamic performance. The setup should increase performance and decrease lag. There's no word on what car this setup will make an appearance on, but it will most likely be used in premium vehicles before trickling down to the rest of GM's vehicles. Related Video: News Source: GM Inside News, AutoGuide via GM Authority Cadillac Chevrolet GM Technology Sedan turbo patent engine turbocharging