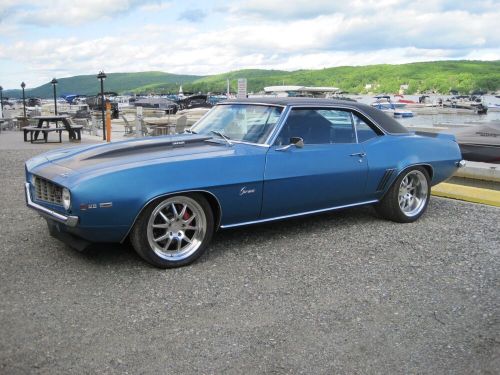

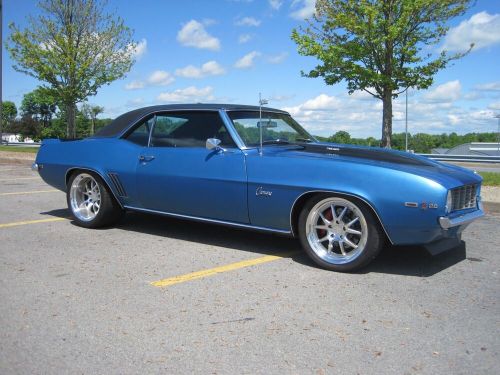

1969 Chevrolet Camaro on 2040-cars

Middletown, New York, United States

Transmission:Manual

Vehicle Title:Clean

Mileage: 2134

Interior Color: Black

Number of Seats: 5

Model: Camaro

Exterior Color: Blue

Make: Chevrolet

Chevrolet Camaro for Sale

1967 chevrolet camaro ss 454 lsx nos wilwood brakes mini tub weld wheels(US $59,995.00)

1967 chevrolet camaro ss 454 lsx nos wilwood brakes mini tub weld wheels(US $59,995.00) 1969 chevrolet camaro(US $100.00)

1969 chevrolet camaro(US $100.00) 1970 chevrolet camaro z-28 prostreet(C $68,885.00)

1970 chevrolet camaro z-28 prostreet(C $68,885.00) 1967 chevrolet camaro(US $5,600.00)

1967 chevrolet camaro(US $5,600.00) 1978 chevrolet camaro(US $14,900.00)

1978 chevrolet camaro(US $14,900.00) 1968 chevrolet camaro(US $20,000.00)

1968 chevrolet camaro(US $20,000.00)

Auto Services in New York

Vogel`s Collision ★★★★★

Vinnies Truck & Auto Service ★★★★★

Triangle Auto Repair ★★★★★

Transmission Giant Inc ★★★★★

Town Line Auto ★★★★★

Tony`s Service Center ★★★★★

Auto blog

What's big at the Chicago show | Autoblog Podcast #503

Fri, Feb 10 2017On this week's podcast, Mike Austin and David Gluckman discuss the big debuts at the 2017 Chicago Auto Show. They also recap what they've all been driving lately, and the episode wraps up with Spend My Money buying advice to help you, our dear listeners. And there's an awful Dad Joke thrown in there for you to find. The rundown is below. Remember, if you have a car-related question you'd like us to answer or you want buying advice of your very own, send a message or a voice memo to podcast at autoblog dot com. (If you record audio of a question with your phone and get it to us, you could hear your very own voice on the podcast. Neat, right?) And if you have other questions or comments, please send those too. Autoblog Podcast #503 The video meant to be presented here is no longer available. Sorry for the inconvenience. Topics and stories we mention Jaguar XE Volkswagen Golf R Toyota Highlander Hybrid Chicago Auto Show coverage Used cars! Rundown Intro - 00:00 What we're driving - 01:46 Chicago show preview - 22:58 Spend My Money - 35:36 Total Duration: 52:48 Get The Podcast iTunes – Subscribe to the Autoblog Podcast in iTunes RSS – Add the Autoblog Podcast feed to your RSS aggregator MP3 – Download the MP3 directly Feedback Email – Podcast at Autoblog dot com Review the show on iTunes Podcasts Chicago Auto Show Chevrolet Dodge Jaguar Toyota Volkswagen Truck Hatchback SUV Performance Sedan ford expedition jaguar xe volkswagen golf r 2017 Chicago Auto Show

GM takes heat for aborted Silverado riff on 'Boston Strong' at World Series

Thu, 31 Oct 2013During game five of the World Series, Chevrolet was set to do a spot of marketing for the 2014 Silverado - fans at Busch Stadium in St. Louis would hold up placards that spelled out the words "Silverado Strong," a theme that Chevy has been promoting since the Silverado's launch with the song "Strong," by Will Hoge. The St. Louis promo was ultimately called off, though, over concerns that it'd be insensitive to the visiting Boston Red Sox. (You can see the image of what the stunt would have looked like above, courtesy of one timely Reddit user.)

Now, the Busch Stadium stunt might not have been a big deal, had the St. Louis Cardinals not been playing the Boston Red Sox. Following the tragic events in Boston during the marathon back in April, the phrase "Boston Strong" gained traction among the city's citizens, especially at sporting events. So, you can imagine that Chevy's appropriation of the phrase might not sit well with some fans.

The stunt was ultimately shelved after images of the signs went viral before the game, leading to a bit of a public backlash. Chevy spokesperson Michael Albano said of the promo that it was meant to show the brand's "commitment to baseball and its fans." But after the images went viral, the company "realized there was the possibility that we may offend some of the very fans we were trying to honor," Albano told Automotive News via email.

Here are your 2016 North American Car and Truck/Utility of the Year finalists [w/polls]

Tue, Dec 8 2015The 2016 Detroit Auto Show will kick off with the announcement of the annual North American Car and Truck/Utility of the Year awards, and the three finalists in each category have just been revealed. Following this announcement, the jury – which includes Autoblog editor-in-chief Mike Austin – will re-evaluate each candidate before casting a final vote for the winner. This year's finalists are: Car of the Year Chevrolet Malibu Honda Civic Mazda MX-5 Miata Truck/Utility of the Year Honda Pilot Nissan Titan XD Volvo XC90 The 23rd annual awards will be announced on the morning of Monday, January 11. For now, we want to know where you stand. Let us know which vehicles you think should win, by voting in the polls below. Chevrolet Honda Mazda Nissan Volvo north american car of the year NACTOY