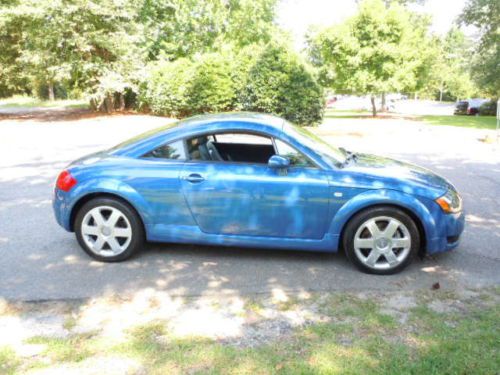

2000 Audi Tt Quattro All Wheel Drive, Great Handling on 2040-cars

Columbia, South Carolina, United States

Audi TT for Sale

2002 audi tt quattro coupe - 225hp, 6-speed manual - mint car!

2002 audi tt quattro coupe - 225hp, 6-speed manual - mint car! 100% feedback we ship clean carfax spoiler leather bucket seats turbo xenons(US $6,800.00)

100% feedback we ship clean carfax spoiler leather bucket seats turbo xenons(US $6,800.00) 2004 audi tt hpa ft400 3.2 turbo(US $18,000.00)

2004 audi tt hpa ft400 3.2 turbo(US $18,000.00) Outstanding black audi tt awd quattro premium plus turbo(US $26,200.00)

Outstanding black audi tt awd quattro premium plus turbo(US $26,200.00) Audi tt convertable, black, clean, 99k, excellant

Audi tt convertable, black, clean, 99k, excellant 3.2 (s-troni coupe 3.2l awd. navigation. leather. only 10k miles

3.2 (s-troni coupe 3.2l awd. navigation. leather. only 10k miles

Auto Services in South Carolina

Wingard Towing Service ★★★★★

Sumter Tire Plus LLC ★★★★★

Stepp`s Garage & Towing ★★★★★

Stateline Auto Brokers ★★★★★

Patterson`s Towing & Recovery ★★★★★

Parish Automotive ★★★★★

Auto blog

Audi RS3 spy shots foreshadow an ultra-hot hatch

Fri, 04 Oct 2013Not all vehicle prototypes and mules require heavy camouflage - sometimes they can be hidden in plain sight. That's probably what Audi was hoping for while testing its new RS3 wearing S3 duds, but thanks to some visual and audible telltales, our spy photographers were able to recognize this as a precursor to the marque's ultra-hot hatch testing near the Nürburgring.

Our photographer noticed the signature exhaust note of a five-cylinder engine, which suggests the RS3 could borrow its motivation from the excellent TT RS. Producing at least 340 horsepower, this 2.5-liter turbo powerplant could be the perfect answer for the new A45 AMG from Mercedes-Benz. The big brakes on this RS3 mule give us our best idea about the car's high-performance intentions, with Audi RS wave brake rotors and six-piston calipers peering out from behind the oversized wheels.

In production form, the RS3 should have a much different appearance from what you see here, with sportier design cues including oval-shaped dual exhaust outlets and a more aggressive front fascia. While we're still waiting for our first taste of the S3 in the North America, we'll be holding our breath for the RS3 to make its way here, as well.

Next Audi R8 to eschew engine downsizing, go on diet instead

Wed, 26 Jun 2013Looking across the Audi landscape, many models that used to get the company's high-revving, naturally aspirated 4.2-liter V8 are now powered by smaller, yet similarly powerful, forced-induction engines. From what Auto Express is reporting, though, the next-generation Audi R8 will not meet this same fate.

Rather than ditching its V8 and V10 powerplants, the next-gen R8 - expected to debut in 2015 - will shed pounds from its curb weight. The 2014 R8 currently weighs between 3,583 pounds and up to 3,957 pounds, but the report says that engineers are targeting a weight of less than 3,300 pounds. All models will get cylinder deactivation, which along with lower curb weights should help to improve fuel economy and emissions. Head on over to Auto Express for more reported information as well as a handful of renderings that take a stab at how the next R8 may look.

Audi Canada surprises out-of-warranty owners in a good way

Wed, 24 Jul 2013One of the worst parts about going to a dealership is sitting around waiting for the courtesy shuttle to show up and transport a group of strangers to their places of work or homes. Well, Audi of Canada found a nice way to surprise customers who brought their out-of-warranty vehicles in for a scheduled Health Check by replacing dealer's normal shuttle with a 2014 Audi R8 V10.

The R8, painted to resemble a safety car or police car, gave the customers a ride home - even stopping at a coffee shop along the way. Needless to say, the stunt got plenty of attention from passers-by and was quite a hit with the Audi customers, too. Scroll down to watch video of the customers getting the ride of a lifetime, which we're sure left some of the in-warranty customers at least a little jealous as they drove off in dealer loaner cars.