1997 Acura Cl Premium Coupe 2-door 2.2l on 2040-cars

Loma Linda, California, United States

|

2.2L V6 Gas, Automatic, AM/FM Radio Cruise Control, Tilt Wheel, Power Window and Locks, Sunroof, Power Leather Seats. New Tires, Smog checked, DMV registration til January 2015 Exterior and Interior in excellent condition! Only 59,240 actual mileage Contact me (909 379-9043 or at (310) 619-4133 $6,500.00/ obo |

Acura CL for Sale

1997 acura cl premium coupe 2-door 3.0l(US $3,500.00)

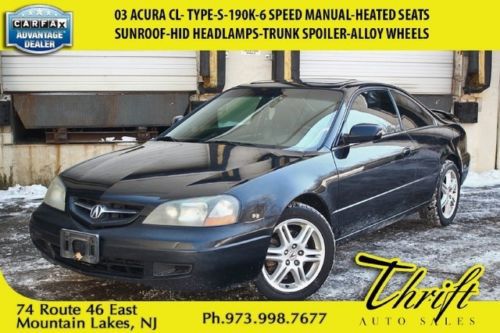

1997 acura cl premium coupe 2-door 3.0l(US $3,500.00) 03 acura cl-type-s-190k-6 speed manual-heated seats-sunroof-hid headlamps(US $4,995.00)

03 acura cl-type-s-190k-6 speed manual-heated seats-sunroof-hid headlamps(US $4,995.00) No reserve 2003 acura 3.2 cl coupe 3.2l v6 auto sunroof bose one owner nice!

No reserve 2003 acura 3.2 cl coupe 3.2l v6 auto sunroof bose one owner nice! 2003 acura cl type s luxury sport coupe(US $10,500.00)

2003 acura cl type s luxury sport coupe(US $10,500.00) 1997 acura cl premium coupe 2-door 2.2l(US $970.00)

1997 acura cl premium coupe 2-door 2.2l(US $970.00) 2003 acura cl type s(US $5,000.00)

2003 acura cl type s(US $5,000.00)

Auto Services in California

Windshield Repair Pro ★★★★★

Willow Springs Co. ★★★★★

Williams Glass ★★★★★

Wild Rose Motors Ltd. ★★★★★

Wheatland Smog & Repair ★★★★★

West Valley Smog ★★★★★

Auto blog

Honda and Acura render their future visions for Shanghai

Mon, 08 Apr 2013With the Shanghai Motor Show coming up later this month, Honda has released a couple of teaser sketches for two concept vehicles that will be making global debuts. Aside from the renderings, there is no information about either the Honda or Acura concept vehicles, but we can tell that both are some sort of utility vehicle, be they of crossover or people-mover variety.

The text for both images indicates that both concepts show future products that will be launched in China, but there is no mention as to what other markets the automaker has planned for these vehicles. In addition to these two concepts, the NSX Concept and 2014 RLX from Acura will make their Chinese debuts, and Honda says it "will display models substantially identical to the mass-production version of the Concept C and Concept S." The Concept C is will be a "middle-class" sedan built for China, and the Concept S, an MPV that will primarily serve China as well.

LoveFab headed back to Pikes Peak with NSX-based heathen [w/video]

Tue, 02 Apr 2013LoveFab had a rough run at Pikes Peak 2012. During qualifying on Day Two, owner and professional driver Cody Loveland launched his car off of the course at nearly 60 miles per hour. Never ones to be dismayed by a few bruised ribs and some busted body panels, LoveFab is headed back to the hill climb for 2013, and this year, it's bringing Garrett along as a title sponsor.

Loveland's chariot of choice is officially dubbed "Turbo by Garrett/LoveFab Pikes Peak Enviate" and is loosely based on an Acura NSX. All of the stock Japanese components have been swapped for LoveFab-built pieces with the exception of the subframes and suspension.

With a dry-sump LS1 V8, chromoly-tube chassis and a full carbon fiber body, the car is about as wild as they come. With around 800 pound-feet of torque on hand and a curb weight of under 2,000 pounds, the machine should give the mountain a run for its money. The team is expected to begin testing Enviate beginning May 1. You can check out a quick interview with Loveland in the video below along with the full press release.

Honda slowing US production due to ports dispute

Thu, Feb 19 2015The labor dispute that idled 29 ports on the West Coast last the weekend, including Los Angeles and Long Beach, CA, is about to make its effects felt on the showroom floor, according to Reuters. Honda, Toyota and Subaru have been trying to work around the labor disagreement, cutting overtime and airlifting parts to factories, but Honda says parts shortages at plants in Indiana, Ohio and Ontario, Canada, are now severe enough to impede production. The lack of transmissions and some electronic components will slow output of the Honda Accord, Civic, and CR-V – as well as unnamed Acuras. The three affected factories will rework their production schedules from Feb. 16-23. The ports have reopened this week, and US Labor Secretary Tom Perez has flown to San Francisco to mediate a new agreement between the 20,000 dockworkers represented by the International Longshore and Warehouse Union and the Pacific Maritime Association, which represents the terminals and shipping companies. Talks have been going on for almost nine months and the issues aren't settled; meanwhile, the West Coast ports that handle half the nation's maritime cargo and 70 percent of cargo from Asia are putting all kinds of industries on the ropes, and it's estimated to cost the economy $2 billion a day. Related Video: News Source: ReutersImage Credit: MARK RALSTON/AFP/Getty Images Government/Legal Plants/Manufacturing UAW/Unions Acura Honda Crossover Sedan