1.5l Auxiliary Audio Input Cruise Control Bluetooth One Owner Traction Control on 2040-cars

Sanford, Florida, United States

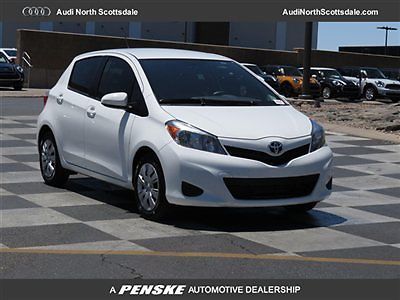

Toyota Yaris for Sale

1.5l front wheel drive aux audio input abs brakes traction control(US $9,900.00)

1.5l front wheel drive aux audio input abs brakes traction control(US $9,900.00) 2007 toyota yaris sedan 4-door 1.5l(US $7,500.00)

2007 toyota yaris sedan 4-door 1.5l(US $7,500.00) 2007 toyota manual

2007 toyota manual 2014 toyota yaris auto 10961 miles factory warranty no accidents financing

2014 toyota yaris auto 10961 miles factory warranty no accidents financing 2007 toyota yaris s sedan 4-door 1.5l(US $5,200.00)

2007 toyota yaris s sedan 4-door 1.5l(US $5,200.00) 2011 toyota yaris sedan, non salvage, damaged, runs and drives,

2011 toyota yaris sedan, non salvage, damaged, runs and drives,

Auto Services in Florida

Y & F Auto Repair Specialists ★★★★★

X-quisite Auto Refinishing ★★★★★

Wilt Engine Services ★★★★★

White Ford Company Inc ★★★★★

Wheels R US ★★★★★

Volkswagen Service By Full Throttle ★★★★★

Auto blog

Hyundai tops Toyota in annual CarMD Vehicle Health Index

Fri, 06 Dec 2013CarMD has released its third annual Vehicle Health Index, which for the 2013 tracked the frequency and cost of repairs for "check engine" problems of 119-million vehicles built between the 2003 and 2013 model years. For the first two years of the index, Toyota ranked at the top of the list, but this year's results see Hyundai moved to number one, pushing Toyota down a spot.

The Korean automaker's rise to the top has been "fueled by its low repair frequency," according to CarMD. Toyota is second to Hyundai in lowest repair frequency, but Toyotas also have the highest average cost of repair. (Interestingly, General Motors vehicles have the lowest average.) Both Toyota's and Hyundai's manufacturer "health" ratings suffered this year, but Toyota took a bigger hit, which also is what helped Hyundai achieve the top ranking.

While Hyundai is the top manufacturer in the index, the 2012 Toyota Camry is the top vehicle. The best-ranking Hyundai was the 2010 Elantra (behind three Nissan models and four Toyotas), which took the number eight spot. Hyundai has six other vehicles in the top 100.

Mini Minor to be co-developed with Toyota

Mon, Jan 26 2015It was back in 2011 when Mini first showcased the prospect of an even smaller hatchback with the Rocketman concept at the Geneva Motor Show. In the nearly four years since, parent company BMW has hemmed and hawed on the possibility of putting it into production, but the latest word from Europe has it that the project is a go. According to Automobile magazine, Mini is realigning its product portfolio into five pillars: the essential hardtop we've already seen (available in two/three- and four/five-doors), the convertible, the upcoming new Clubman wagon (coming this summer with full-size auxiliary suicide doors on both sides), the next-gen Countryman crossover in 2016 and two new model lines. One will be the production version of the Superleggera roadster concept, earmarked for 2018. The other will be the Minor, a smaller city car reviving a long-gone model name and presaged by the aforementioned Rocketman concept. But for that last one, Mini won't go it alone. To develop the mini Mini, BMW will reportedly turn to its partnership with Toyota. The relationship is already set to yield a new Supra and Z4 and share fuel cell and other technologies. But this would broaden the partnership to include a small hatchback. However rather than use the existing (or next-gen) Aygo, which is already built under joint venture with PSA Peugeot Citroen (with which BMW previously had a joint engine venture), word has it that the BMW and Toyota will develop a new platform for the project – one that will be used by both partners. The new product plan doesn't leave much room for the Mini Coupe and Roadster (which have already been discontinued), for the Paceman three-door crossover (which will suffer the same fate) or for the projected seven-seater minivan. But the addition of the new Superleggera roadster and super-mini Mini aren't likely to leave us wanting for either. Related Video:

Toyota retires robots in favor of humans to improve automaking process

Sat, 12 Apr 2014Mitsuru Kawai is overseeing a return to the old ways at Toyota factories throughout Japan. Having spent 50 years at the Japanese automaker, Kawai remembers when manual skills were prized at the company and "experienced masters used to be called gods, and they could make anything." Company CEO Akio Toyoda personally chose Kawai to develop programs to teach workers metalcraft such as how to forge a crankshaft from scratch, and 100 workstations that formerly housed machines have been set aside for human training.

The idea is that when employees personally understand the fabrication of components, they will understand how to make better machines. Said Kawai, "To be the master of the machine, you have to have the knowledge and the skills to teach the machine." Lessons learned by the newly skilled workers have led to shorter production lines - in one case, 96percent shorter - improved parts production and less scrap.

Taking time to give workers the knowledge to solve problems instead of merely having them "feed parts into a machine and call somebody for help when it breaks down," Kawai's initiative is akin to that of Toyota's Operations Management Consulting Division, where new managers are given a length of time to finish a project but not given any help - they have to learn on their own. It's not a step back from Toyota's quest to build more than ten million cars a year; it's an effort to make sure that this time they don't sacrifice quality while making the effort. Said Kawai, "We need to become more solid and get back to basics."