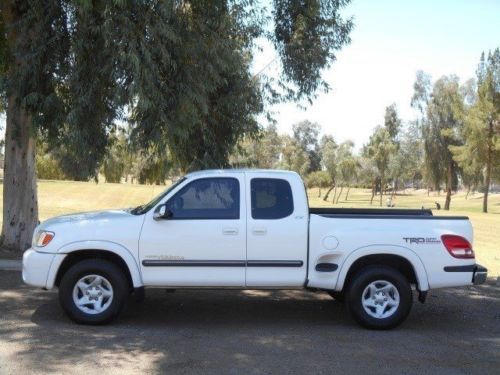

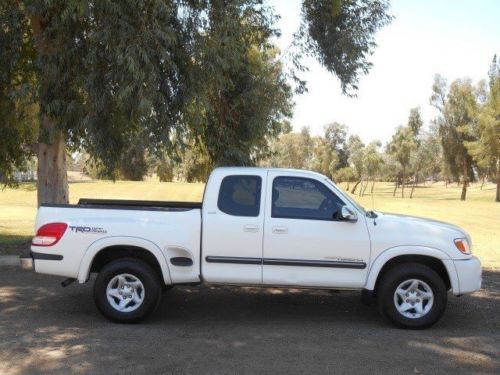

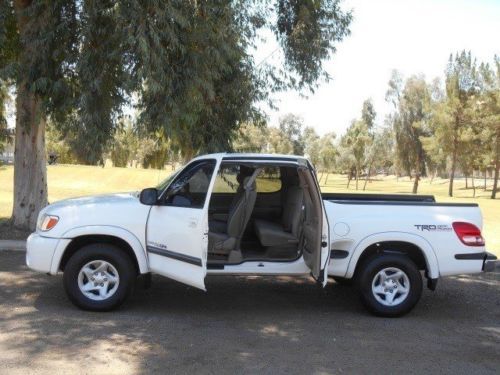

Sr5 4.7l Cd 4x4 Tires - Front On/off Road Tires - Rear On/off Road Steel Wheels on 2040-cars

Mesa, Arizona, United States

Toyota Tundra for Sale

2005 toyota tundra limited extended cab pickup 4-door 4.7l no reserve

2005 toyota tundra limited extended cab pickup 4-door 4.7l no reserve 2006 toyota tundra limited extended cab pickup 4-door 4.7l(US $18,000.00)

2006 toyota tundra limited extended cab pickup 4-door 4.7l(US $18,000.00) Lifted 5.7 liter tundra crew leather power boards dvd's 2wd bedliner fuel rims(US $26,995.00)

Lifted 5.7 liter tundra crew leather power boards dvd's 2wd bedliner fuel rims(US $26,995.00) Ltd 5.7l cd locking/limited slip differential rear wheel drive power steering

Ltd 5.7l cd locking/limited slip differential rear wheel drive power steering Toyota tundra sr5 4x4,double cab,lifted,leather seats,cruise control,aux/cd,gr8!(US $26,980.00)

Toyota tundra sr5 4x4,double cab,lifted,leather seats,cruise control,aux/cd,gr8!(US $26,980.00) Tundra sr5 2006 green automatic 4.7l v8 4x4 crew cab one owner clean carfax

Tundra sr5 2006 green automatic 4.7l v8 4x4 crew cab one owner clean carfax

Auto Services in Arizona

Vistoso Automotive ★★★★★

Vette Shoppe ★★★★★

Tempe Imports ★★★★★

Suntec Auto Glass & Tinting ★★★★★

Smarts Automotive ★★★★★

Real Fast Auto Glass ★★★★★

Auto blog

2014 Toyota Corolla and Tundra production underway

Fri, 02 Aug 2013After months of leaked photos and speculative reports, Toyota finally unveiled its 2014 Corolla to the world in early July at a star-studded California party. The confetti has been swept up and the champagne flutes washed and stored, and now the real work can begin: production. Toyota has announced that its new C-segment player has begun rolling off the lines at its plants in Mississippi and Ontario, Canada this week ahead of the planned start of sales in September. What's more, the refreshed 2014 Tundra pickup has also segued into production in San Antonio, Texas.

Corolla production in Mississippi is still a relatively recent phenomenon, with the plant having begun assembly of the outgoing model in the fourth quarter of 2011, while Toyota's Cambridge, Ontario plant has been churning out the compact volume king since 1988. Conversely, the Tundra has been in production at the Texas facility since 2006, and Toyota projects that the plant will build its milestone one-millionth new vehicle in September, right around the time the reworked fullsize pickup goes on sale.

Toyota, Daihatsu and Suzuki team up to unbox some fun-size electric kei vans

Thu, May 18 2023The G7 Summit is happening in Hiroshima, Japan, right now and some automakers have taken the opportunity to announce new projects. Toyota, their wholly owned subsidiary Daihatsu, and Suzuki (of which Toyota owns about 5%) made news with a trio of electric micro-vans built to kei car specifications. The battery-electric vans are part of an industry-wide push toward carbon neutrality. Kei-class vehicles, in addition to limited displacement gasoline engines, have strict dimensional restrictions that allow them to navigate the often narrow streets in dense urban areas. They're also privilege to certain tax breaks and parking benefits. [gallery ids="2474953,2474954"] The engine size rules obviously don't apply to the electric vans, but they will still conform to the size boundaries. Kei vans are often used to solve the "last mile" problem in logistics since they're able to whiz around crowded streets inaccessible by larger commercial vehicles. Daihatsu, which specializes in kei cars, will build the vans and name their variant the HiJet Cargo. The HiJet name has been a consistent one in the company's lineup since 1960, but these new versions will be front-wheel-drive in contrast to the rear-wheel-drive gasoline variants. Toyota's version will be called the Pixis Van, while Suzuki will be named the Every, a nameplate that's been around since 1982. Aside from the badges the vans appear identical. Range is said to be approximately 200km (124 miles) on a single charge. The exhibition was held in conjunction with the Japan Automobile Manufacturers Association, which former Toyota CEO Akio Toyoda heads. Toyoda stepped down from the top position at the company his grandfather founded in April, but still takes a overseer role as Chairman. Toyoda was criticized for being slow to adopt EVs, and new CEO Koji Sato has emphasized the role of battery-electrics moving forward while still taking a multi-front approach to carbon neutrality with hydrogen and hybrids. These vans were likely in development before Toyoda's retirement, though.

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.