Model Iv Hybrid-electric Certified 1.8l Leather Navigation Bluetooth Jbl Audio on 2040-cars

Lake Havasu City, Arizona, United States

Vehicle Title:Clear

Engine:1.8L 1798CC 110Cu. In. l4 ELECTRIC/GAS DOHC Naturally Aspirated

For Sale By:Dealer

Body Type:Hatchback

Fuel Type:ELECTRIC/GAS

Interior Color: Tan

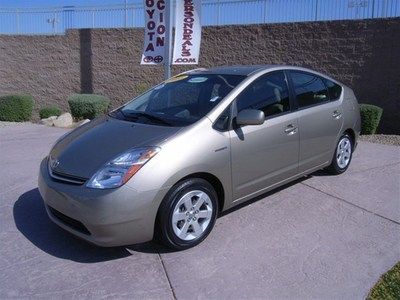

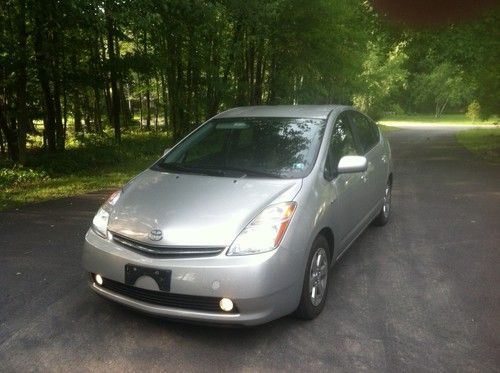

Make: Toyota

Model: Prius

Warranty: Vehicle has an existing warranty

Trim: Base Hatchback 4-Door

Drive Type: FWD

Number of Doors: 4 Generic Unit (Plural)

Mileage: 55,579

Sub Model: model 4

Number of Cylinders: 4

Exterior Color: White

Toyota Prius for Sale

Model ii hybrid-electric certified 1.5llow miles full power features ac am/fm/cd

Model ii hybrid-electric certified 1.5llow miles full power features ac am/fm/cd 2001 toyota prius hybrid - 1 family owned - original miles - rebuilt battery(US $3,995.00)

2001 toyota prius hybrid - 1 family owned - original miles - rebuilt battery(US $3,995.00) Factory certified 2012 toyota prius plug-in 5dr hb -less than 10k miles!!!(US $28,000.00)

Factory certified 2012 toyota prius plug-in 5dr hb -less than 10k miles!!!(US $28,000.00) 2012 toyota prius plug-in(US $36,990.00)

2012 toyota prius plug-in(US $36,990.00) 2006 toyota prius hybrid,back up camera,clean title,jbl,no reserve!!

2006 toyota prius hybrid,back up camera,clean title,jbl,no reserve!! 2006 toyota prius base hatchback 4-door 1.5l

2006 toyota prius base hatchback 4-door 1.5l

Auto Services in Arizona

Wades Discount Muffler, Brakes & Catalytic Converters ★★★★★

Unique Auto Repair ★★★★★

Transmission Plus ★★★★★

Super Discount Transmissions ★★★★★

Suntec Auto Glass & Tinting ★★★★★

Sluder`s Garage ★★★★★

Auto blog

Ford F-150 could be affected by tornado-damaged supplier in S.C.

Wed, Apr 22 2020The disruption caused by a tornado that severely damaged a South Carolina auto-parts plant and killed a contract security guard last week could be felt by more automakers than just Ford and affect more than just its best-selling F-Series pickup, which is due for an update. And there’s still no estimate for when operations might resume at the plant. The Detroit Free Press reports that the BorgWarner plant in Seneca, near Greenville, makes transfer cases for F-150 and Super Duty pickups, the Ford Explorer and Expedition, Transit cargo vans, and Lincoln Navigator and Aviator SUVs. ItÂ’s also a supplier for the Ram 1500 and Toyota Tundra trucks. Transfer cases shift power from the transmission to the front and rear axles in four-wheel-drive vehicles. BorgWarner says it still has no update for when it might partially or fully resume operations. The tornado that ripped through the area in the western part of the state on April 13 tore the roof, walls and signage off the factory and killed a 77-year-old contract worker when the security building he was sheltering in collapsed. Only four or five others were inside the plant, which has been idled because of the coronavirus outbreak, when the tornado struck. In an SEC filing on Friday, Ford said it has sent employees to the site to help BorgWarner and assess the damage to FordÂ’s tooling. “Initial assessments indicate that the Ford tooling was not materially damaged in this incident,” Ford said in the filing. “We do not have sufficient information to estimate when the facility will be back on-line or whether or the extent to which this incident will impact our plans to resume production of four-wheel drive and all-wheel drive vehicles.” A Fiat Chrysler spokeswoman also told the Freep the company was working with BorgWarner on recovery plans. A Toyota spokesman told Autoblog that "we are collaborating with BorgWarner to help restore production for transfer cases for Tundra assembly. We are confident that theyÂ’ll fully recover over time." Like other automakers, Ford shut down production at its U.S. plants last month as a precaution against the coronavirus pandemic. But Ford hasnÂ’t yet said when it plans to reopen its factories. FCA is targeting May 4 to resume production. Models like the F-150 and Lincoln Navigator are major sources of profit for Ford, which estimated it lost $2 billion in the first quarter.

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.

DoJ fines Japanese parts firms $740M in massive automotive price-fixing scandal

Fri, 27 Sep 2013Nine Japanese suppliers have pleaded guilty in US court over charges of price fixing in the automotive parts industry, resulting in the Department of Justice doling out a total of $740 million of fines, according to a report from Bloomberg. The scandal, which has resulted in General Motors, Ford, Toyota and Chrysler spending up to $5 billion on inflated parts and driving up prices on 25 million vehicles has sent the DoJ hustling into investigations. "The conduct this investigation uncovered involved more than a dozen separate conspiracies aimed at the U.S. economy," Attorney General Eric Holder (pictured above) said during yesterday's press conference.

As the investigation stands, the DoJ has issued $1.6 billion in fines against 20 companies and 21 individual executives, with 17 of the execs headed to prison. Deputy Assistant Attorney General Scott Hammond said, "The breadth of the conspiracies brought to light today are as egregious as they are pervasive. They involve more than a dozen separate conspiracies operating independently but all sharing in common that they targeted US automotive manufacturers."

Big-name suppliers indicted in the investigation include Mitsubishi Electric, Mitsubishi Heavy Industries, Hitachi Automotive and Mitsuba Corporation. A list of fines and other corporations named in the investigation is available at Bloomberg.