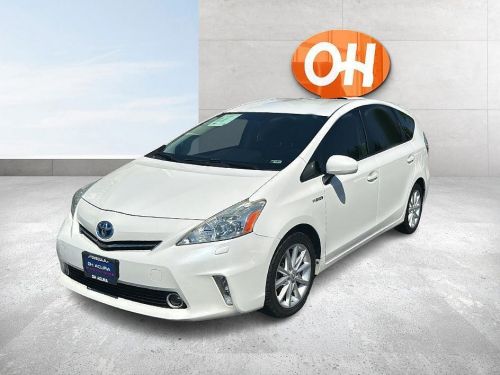

2013 Toyota Prius V Five on 2040-cars

Temecula, California, United States

Engine:4 Cylinder Engine

Fuel Type:Gasoline

Body Type:Wagon

Transmission:--

For Sale By:Dealer

VIN (Vehicle Identification Number): JTDZN3EU1D3212075

Mileage: 123526

Make: Toyota

Trim: Five

Drive Type: --

Features: --

Power Options: --

Exterior Color: White

Interior Color: Gray

Warranty: Unspecified

Model: Prius V

Toyota Prius V for Sale

2017 toyota prius v five 4dr wagon(US $15,999.00)

2017 toyota prius v five 4dr wagon(US $15,999.00) 2014 toyota prius v five(US $10,900.00)

2014 toyota prius v five(US $10,900.00) 2014 toyota prius v five(US $14,023.00)

2014 toyota prius v five(US $14,023.00) 2012 toyota prius v wagon lthr bk/cam hwy miles fresh trade in(US $12,295.00)

2012 toyota prius v wagon lthr bk/cam hwy miles fresh trade in(US $12,295.00) 2016 toyota prius v four(US $12,873.70)

2016 toyota prius v four(US $12,873.70) 2013 toyota prius v(US $8,995.00)

2013 toyota prius v(US $8,995.00)

Auto Services in California

Zoll Inc ★★★★★

Zeller`s Auto Repair ★★★★★

Your Choice Car ★★★★★

Young`s Automotive ★★★★★

Xact Window Tinting ★★★★★

Whitaker Brake & Chassis Specialists ★★★★★

Auto blog

Toyota's Bob Carter says seat heater stop-sale due to inconsequential compliance error

Sat, Feb 8 2014Last week, Toyota let it be known that a number of its more-popular vehicles were subject to a "stop-sale" order due to faulty seat heaters on these vehicles. No injuries were reported, but the problem affected a lot of models, including the 2013 and 2014 Camry, Camry Hybrid, Avalon, Avalon Hybrid, Sienna, Corolla, Tacoma and Tundra. Toyota originally said 50,000 vehicles were involved, but Bob Carter, senior vice president of automotive operations for Toyota Motor Sales, knocked that down to 30,000 during an interview at the Chicago Auto Show this week and said that the problem is not going to have a big impact on Toyota's sales. "It's an important situation but it will have a very minor impact on February sales," he told AutoblogGreen. "Dealers will start receiving new heating elements this week and then we have a process to take out the heating element that was put in and exchange that for the new fabric. It's very simple. It's a quick repair." Quick in this situation means about three hours to swap out the heating elements in two seats, according to Toyota's John Hanson. Since the Avalon also has heated rear seats, that car will require a total of six hours in the shop. Hanson said there was no official timeline for when the exchange program would be completed, "but new vehicles are arriving at some dealerships with the new seat heaters already installed." With a fix already in place, Carter would not comment on whether a recall is likely, saying only, "I'm not the expert on that. We're working with the NHTSA and ultimately it's their decision. We believe it's an inconsequential compliance error that was made by one of our suppliers and we're going to correct it." Featured Gallery 2013 Toyota Camry Hybrid: Review View 23 Photos News Source: Toyota Green Chicago Auto Show Toyota AutoblogGreen Exclusive Hybrid camry hybrid bob carter

Toyota, Suzuki partner on hybrids, EVs, building cars for each other

Wed, Mar 20 2019NAGOYA, Japan — Toyota and Suzuki on Wednesday said they planned to produce electric vehicles and compact cars for each other to better compete with fast-changing technologies in the global auto industry. The agreement follows an initial R&D tie-up announced by Japan's No. 1 and No. 4 automakers in 2017, and will see more vehicles produced by Suzuki for Toyota, one of the world's biggest carmakers. Although Suzuki is far smaller, it is a dominant force in the fast-growing Indian market. The two automakers have been pooling their strengths. Toyota is a leader in hybrid technology and is investing heavily in automated driving, while Suzuki specializes in affordable compact cars — as many automakers struggle to keep pace with ballooning investment in EVs and self-driving cars. Under the latest agreement, Suzuki will source gasoline hybrid systems for cars it sells worldwide from Toyota, which pioneered hybrid vehicles with the Prius more than 20 years ago, the companies said in a joint statement. In return, Suzuki will produce two compact models for Toyota in India based on its Ciaz and Ertiga models. Further cooperation with Suzuki will help Toyota expand its presence in India, the world's fifth-largest passenger car market where it has struggled to grow sales due to lean demand for its lower-cost models. The deepening partnership between the two automakers will enable cost-conscious Suzuki to tap into Toyota's R&D firepower to develop lower-emission vehicles and self-driving cars — areas which Suzuki has admitted it is struggling to keep up. "We believe that the expansion of our business partnership with Suzuki ... will help give us the competitive edge we will need to survive this once-in-a-century period of profound transformation," Toyota President Akio Toyoda said in a statement. The two automakers will deepen their cooperation in India, where Suzuki's hybrid vehicles will be made using engines and batteries locally produced by Toyota. They will also join forces in Europe, where Toyota will produce electric vehicles based on its RAV4 SUV crossover and Corolla wagon for Suzuki, while Suzuki will supply Toyota with gasoline engines for compact vehicle models sold in the region. Suzuki will also produce its Baleno, Vitara Brezza, Ciaz, and Ertiga models for Toyota which will be rebranded and renamed as Toyota models for the African market.

Andrew Gilleland is new VP of Scion, Murtha moves to Toyota

Fri, Sep 25 2015Scion is getting some fresh blood at the top as Andrew Gilleland (pictured above) becomes the new vice president to take over for Doug Murtha. Gilleland is no stranger to the division, and served as the national field operations manager early in the brand's launch. Murtha moves to take leadership of corporate strategy and planning for Toyota in North America. "Now it's Andrew's charge to spread the message of the style and value of the iM and iA, as well as a third new vehicle that will be added to the lineup," Toyota division group vice president Bill Fay said in the announcement. Gilleland moves up from being general manager of Toyota's central Atlantic regional office. He takes the reins at Scion at a potential turning point for the division. Sales volume for the year through August is down 22.1 percent to 32,691 vehicles, but some big changes are afoot. The long-lived xB is likely about to bow out, and the brand is launching two new products with the iM and iA. They're getting some celebrity advertising, too. Spy shots also suggest the FR-S might get a refresh soon. Plus, the third model Fay teases is expected to be a compact crossover, possibly with styling inspiration from the Toyota C-HR concept. Scion could get a big boost by having an entry in that booming segment. New Products, Previous Player - Scion Introduces New Vice President Andrew Gilleland Returns to Youth Brand September 24, 2015 TORRANCE, Calif. (Sept. 24, 2015) – In the early days of Scion, when xAs and xBs were flying out of dealers' showrooms, Andrew Gilleland was the National Field Operations Manager for the youth brand. He was responsible for working with dealers to ensure they embraced the new products and processes Scion offered. Now, Scion is entering its teen years, and Gilleland is back as Vice President of Scion, once again encouraging dealers to sell its new models and investigate new methods to attract young buyers. "Scion has sold nearly a million vehicles since I left in 2005 and I'm excited to be back leading this team," said Gilleland. "The iM 5-door hatchback and iA sports sedan arrived at dealerships earlier this month and the response has been great.