Se Convertible 3.3l Cd 6 Speakers Am/fm Radio Am/fm Stereo W/6cd & 6 Speakers on 2040-cars

Little Rock, Arkansas, United States

Toyota Camry for Sale

1997 toyota camry le sedan 4-door 2.2l priced to sell!(US $2,300.00)

1997 toyota camry le sedan 4-door 2.2l priced to sell!(US $2,300.00) Fl one owner highway miles rare v6 manual drives new cold ac cd pw cruise pl ps

Fl one owner highway miles rare v6 manual drives new cold ac cd pw cruise pl ps 1994 toyota camry no reserve

1994 toyota camry no reserve 2002 toyota camry no reserve

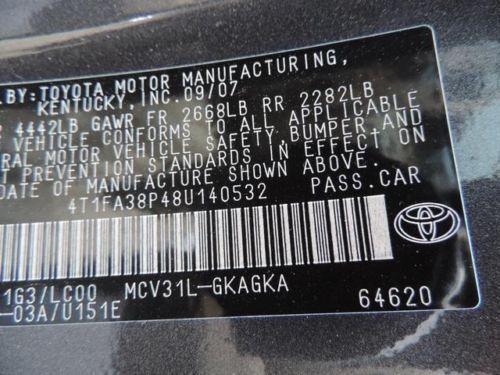

2002 toyota camry no reserve 2007 toyota camry se sedan 4-door 3.5l(US $9,500.00)

2007 toyota camry se sedan 4-door 3.5l(US $9,500.00) 2012 toyota camry 4dr sdn i4 auto se(US $21,992.00)

2012 toyota camry 4dr sdn i4 auto se(US $21,992.00)

Auto Services in Arkansas

Wayne`s Auto Sales ★★★★★

Texarkana Glass Co ★★★★★

Tcc Auto ★★★★★

T.T.S. Tire & Auto ★★★★★

Pruitt`s Auto Parts ★★★★★

Northwest Arkansas Collision Center ★★★★★

Auto blog

Toyota finds profit in Europe thanks to hybrid sales

Thu, Jun 5 2014In the land of diesel, Toyota appears to be making money its own way and thereby making more of it. The Japanese automaker is taking on Europe's diesel-centric ways by substantially boosting sales of hybrids on the continent. That, along with cost cutting measures, has increased the company's European profitability, Automotive News says, citing recent remarks by Toyota's European operations chief Didier Leroy. Toyota, which lost money in Europe between 2008 and 2011, started turning things around two years ago by cutting labor at places like UK factories while consolidating production of models such as the Auris and Yaris hybrid vehicles. During the most recently completed financial year, Toyota Europe reported earnings that were up 75 percent from the year before, despite revenue being up just five percent. The company also aims to sell at least 1 million vehicles in Europe by next year and is boosting sales in countries like Russia. Late last year, Didier told Bloomberg News that Toyota's European market share was rising about one percentage point a year, while production at Toyota's factories in countries like France, Turkey and the UK were running at full capacity. Toyota estimated at the time that hybrids accounted for about a fifth of Toyota's European sales.

Toyota produces millionth truck in Texas

Thu, 19 Sep 2013After going online in 2006, Toyota's San Antonio, Texas truck plant has just built its one-millionth vehicle, the 2014 Tundra 1794 Edition you see above. The plant originally focused on just the Tundra pickup, but the smaller Tacoma started rolling off the line there in 2010, as well.

Fittingly, the 1794 Edition (a new premium trim level for 2014) pays homage to the property on which the Toyota plant now resides - a ranch that was founded in 1794. Scroll down for the official press release for the plant's milestone, and be sure to check out the full gallery of Tundra 1794 Edition images as well.

New Prius, Bentley Bentyaga, Rolls-Royce Dawn | Autoblog Minute

Sat, Sep 12 2015Bentley and Rolls-Royce introduce new luxury vehicles and Toyota revealed its latest Prius. Autoblog Senior editor Greg Migliore reports on the Weekly Recap edition of Autoblog Minute. Bentley Rolls-Royce Toyota Convertible SUV Hybrid Autoblog Minute Videos Original Video bentley bentayga rolls-royce dawn