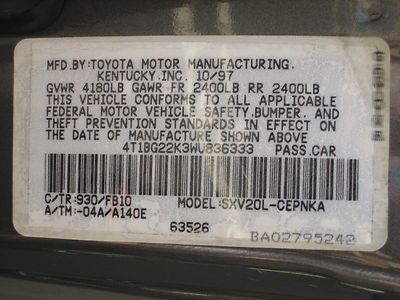

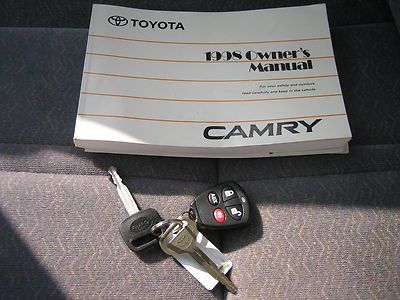

1998 Toyota Camry Le One Owner Only 61k Miles Non Smoker No Accidents No Reserve on 2040-cars

Huntingdon Valley, Pennsylvania, United States

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Dealer

Transmission:Automatic

Make: Toyota

Warranty: Vehicle does NOT have an existing warranty

Model: Camry

Mileage: 61,400

Options: Sunroof

Sub Model: 4dr Sdn LE

Safety Features: Anti-Lock Brakes

Exterior Color: Other

Power Options: Power Windows

Interior Color: Gray

Number of Cylinders: 4

Vehicle Inspection: Inspected (include details in your description)

Toyota Camry for Sale

Auto Services in Pennsylvania

Young`s Auto Body Inc ★★★★★

West Shore Auto Care ★★★★★

Village Auto ★★★★★

Ulrich Sales & Svc ★★★★★

Trust Auto Sales ★★★★★

Steve`s Auto Body & Repair ★★★★★

Auto blog

Union to launch Toyota organization drive in Canada

Sun, 12 Jan 2014Toyota may be heading toward some labor issues in the Great White North, as employees at a pair of Canadian Toyota factories may be set for a certification vote. The Unifor union, which was the result of a merger last year between the Canadian Auto Workers and the Communications, Energy and Paperworkers union, will be holding the vote.

Over 40 percent of the employees at the Woodstock and Cambridge, Ontario factories have signed union cards, cresting the minimum percentage required to instigate a legal certification vote, according to Reuters. The Woodstock factory is responsible for RAV4 production, while Cambridge builds the Lexus RX350 and RX450h, as well as the Toyota Corolla. The two factories employ nearly 7,000 people.

It's unclear when the union will hold a certification vote at the two factories, but what is rather clear are the worker complaints. Employees are concerned about workers being hired on temporary contracts which lack the benefits of full employment, John Aman, head of organizing for Unifor, told Reuters.

Toyota and Lexus will have standard automatic braking by 2017

Sat, Mar 26 2016Last week, NHTSA and IIHS announced that 20 auto manufacturers and three agencies had agreed to include automatic emergency braking (AEB) as standard equipment by 2022. Toyota was one of those 20 companies, but this week they upped the AEB ante: Nearly every Toyota and Lexus model and trim level will have standard AEB by 2017. That's next year. Many models already offer AEB as part of the Lexus Safety System+ and Toyota Safety Sense packages, but consumers have had to pay extra for these options (unless they leased a Toyota Mirai hydrogen fuel-cell vehicle; it already has AEB as standard equipment.) By the end of next year, all but the Lexus GS, Toyota 4Runner and Toyota 86 — which was developed together with Subaru — will have AEB installed at no extra cost. (Interestingly, the new Prius Prime unveiled at the New York International Auto Show has Safety Sense as an option rather than standard equipment.) The AEB function is part of Toyota's safety suites, which will be included in 25 Lexus and Toyota models. Both makes have a precollision system that detects the possibility of collision with the car ahead and engages the brakes if the driver doesn't react quickly enough, as well as lane departure alerts and automatic high beams. Toyota's move leapfrogs ahead of Honda making its Honda Sensing system, which includes AEB tech, available as a flat $1,000 option on every Civic Sedan. Related Video: This article by Kristen Hall-Geisler originally ran on TechCrunch, a leading technology media property, dedicated to obsessively profiling startups, reviewing new Internet products, and breaking tech news.

Tougher than steel: Wood pulp could make lighter auto parts

Tue, Aug 15 2017KYOTO, Japan — The global push among carmakers to make ever lighter vehicles is leading some auto suppliers in Japan to turn to what seems like an unlikely steel substitute — wood pulp. Japanese researchers and auto component makers say a material made from wood pulp weighs just one-fifth of steel and can be five times stronger. The material - cellulose nanofibers — could become a viable alternative to steel in the decades ahead, they say, although it faces competition from carbon-based materials, and remains a long way from being commercially viable.> Related: Jay Leno drives the Renew cannabis car — hemp you can't dent Reducing the weight of a vehicle will be critical as manufacturers move to bring electric cars into the mainstream. Batteries are an expensive but vital component, so a reduction in car weight will mean fewer batteries will be needed to power the vehicle, saving on costs. "Lightweighting is a constant issue for us," said Masanori Matsushiro, a project manager overseeing body design at Toyota. "But we also have to resolve the issue of high manufacturing costs before we see an increased use of new, lighter-weight materials in mass-volume cars."A NEW PROCESS Researchers at Kyoto University and major parts suppliers such as Denso Corp, Toyota's biggest supplier, and DaikyoNishikawa Corp, are working with plastics incorporated with cellulose nanofibers — made by breaking down wood pulp fibers into several hundredths of a micron (one thousandth of a millimeter). Cellulose nanofibers have been used in a variety of products ranging from ink to transparent displays, but their potential use in cars has been enabled by the "Kyoto Process," under which chemically treated wood fibers are kneaded into plastics while simultaneously being broken down into nanofibers, slashing the cost of production to roughly one-fifth that of other processes. "This is the lowest-cost, highest-performance application for cellulose nanofibers, and that's why we're focusing on its use in auto and aircraft parts," Kyoto University Professor Hiroaki Yano, who is leading the research, told Reuters in an interview. The university, along with auto parts suppliers, are currently developing a prototype car using cellulose nanofiber-based parts to be completed in 2020.

2010 toyota camry great price!

2010 toyota camry great price! Gallery edition v6 power moonroof very clean

Gallery edition v6 power moonroof very clean 1999 toyota camry le 4cyl 2.2l engine w/157047 miles,no reserve price auction@@@

1999 toyota camry le 4cyl 2.2l engine w/157047 miles,no reserve price auction@@@ 2008 toyota camry hybrid

2008 toyota camry hybrid 2011 toyota camry xle sedan 4-door 3.5l

2011 toyota camry xle sedan 4-door 3.5l 1995 toyota camry le wagon 4-door 2.2l

1995 toyota camry le wagon 4-door 2.2l