1992 Toyota Camry Xle Sedan 4-door 3.0l on 2040-cars

Frisco, Texas, United States

|

It runs, has a current inspection Electric moon roof Installed a used engine in December, 2013 Paid $600 for the engine. New catalytic converter, June, 2013 New radiator, April, 2014 New brake pads, June, 2013 New ball joints and one new tie rod, June, 2013 The car runs, my son uses it to drive to school and to work,

but next year he starts a 25 mile commute to school, and it needs too much work

before my wife would feel like itís safe. A junkyard will give me $250, so thatís where the reserve is. Things not working Temperature gauge doesnít work. No Heat, No A/C A/C components are R12. Passenger window works, but you need to guide it in place to

seal tight Dent on the hood (see photo) Leather Seats have lots of cracks. The worst is the driver seat Need 2 keys: one for the locks and one for the ignition. I had to replace the key cylinder. Slight exhaust leak Ė not bad, but I know it ran quieter a

few months ago Assume that the original radio is functional but the amplifier

under the seat doesnít work. Did not replace the main rear seal when the engine was

replaced, and it looks like there is a small leak, but nothing shows up on the

ground when parked over night. Small rock chip in the windshield, but no cracks. Needs 4 tires Needs a 4-wheel alignment I have owned for over 12 months. It has a bonded title. The guy who sold it to me signed on the wrong line, and I couldn't locate him after the sale. This car will be sold AS IS - No Warranty. |

Toyota Camry for Sale

2001 toyota camry le sedan 4-door 2.2l

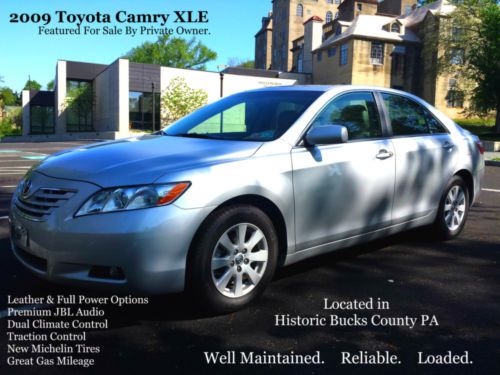

2001 toyota camry le sedan 4-door 2.2l Toyota camry xle v6 with new michelin tires, leather, jbl audio, must see(US $14,500.00)

Toyota camry xle v6 with new michelin tires, leather, jbl audio, must see(US $14,500.00) 2012 toyota camry se sunroof htd seats paddle shift 18k texas direct auto(US $21,480.00)

2012 toyota camry se sunroof htd seats paddle shift 18k texas direct auto(US $21,480.00) 2011 toyota camry xle sunroof heated leather 76k miles texas direct auto(US $16,980.00)

2011 toyota camry xle sunroof heated leather 76k miles texas direct auto(US $16,980.00) 2012 sunroof black leather i4 dohc lifetime warranty we finance 16k miles

2012 sunroof black leather i4 dohc lifetime warranty we finance 16k miles 2001 toyota camry ce sedan 4-door 2.2l(US $6,490.00)

2001 toyota camry ce sedan 4-door 2.2l(US $6,490.00)

Auto Services in Texas

Youniversal Auto Care & Tire Center ★★★★★

Xtreme Window Tinting & Alarms ★★★★★

Vision Auto`s ★★★★★

Velocity Auto Care LLC ★★★★★

US Auto House ★★★★★

Unique Creations Paint & Body Shop Clinic ★★★★★

Auto blog

Audi outlasts rivals to win 13th Le Mans title

Sun, 15 Jun 2014As is so often the case, the 2014 Le Mans was a war of attrition, and Audi managed to prevail once again after all 24 hours had been recorded in the history books, with its Audi R18 E-Tron Quattro claiming first and second places, followed by Toyota in third. Drivers Marcel Fassler, Andre Lotterer and Benoit Treluyer inherited the lead in their No. 2 Audi after the No. 7 Toyota, driven by pole-sitter Kazuki Nakajima, was forced to retire with electrical problems in the 15th hour.

The No. 2 Audi led the race until it was forced to the pits to replace a turbocharger in the 17th hour, allowing the No. 1 Audi, driven by Lucas di Grassi, Marc Gene (who was a last-minute replacement for Loic Duval, who crashed hard during practice) and defending champion Tom Kristensen, led the race until the 21st hour, when it too had to pit with turbocharger issues. This gave the No. 20 Porsche of Timo Bernhard, Brendon Hartley, and Mark Webber the lead until it was forced off the track with gearbox problems, eventually finishing in 38th position.

In LMP2, the Jota Sport Zytek Z11SN-Nissan driven by Simon Dolan, Harry Tincknell and Oliver Turvey claimed victory, the first five LMP2 finishers all powered by Nissan. Down a level in GTE-Pro, No. 51 AF Corse Ferrari 458 Italia GT2 driven by Gianmaria Bruni, Toni Vilander and Giancarlo Fisichella finished one lap ahead of the leading Corvette Racing C7.R. And finally, the No. 95 Aston Martin Racing Vantage GTE driven by Kristian Poulsen, David HeinemeierHansson and Nicki Thiim won the GTE-Am race two laps ahead of a Proton Porsche 911 GT3 RSR.

Toyota moving US headquarters to Plano, Texas

Mon, 28 Apr 2014It's official, Toyota is relocating its US operations to Plano, TX. And it won't be a symbolic 'all ranch and no cattle' gesture - the Japanese automaker, whose headquarters have been in California since 1957, has decided to base nearly all of its operations in the Lone Star State, including much of its engineering, finance and sales and marketing teams.

The move, which will see the establishment of a new headquarters campus in the Dallas suburb will not only affect employees at the company's current Torrance, CA Toyota Motor Sales USA campus, it will also touch the lives of thousands of employees at the company's other operations, including 1,000 workers at Toyota Motor Engineering & Manufacturing North America in Erlanger, KY and some New York-based staff as well. The Toyota Technical Center in Ann Arbor, MI is not facing relocation, however, and it actually stands to gain responsibilities as Toyota overhauls its US org chart. Toyota says that its reorganization will affect about 4,000 employees in total.

According to Automotive News, while Toyota is adopting an "'everyone is invited' stance for the relocation," some attrition is expected from employees who aren't interested in relocating southward from the Golden State. For its part, the automaker is reportedly making expenses-paid visits to Plano available to full-time staffers and spouses to help them make the relocation decision, as well as a lump-sump payment if they decide to go through with the move.

Aging Prius, dropping gas prices putting hurt on hybrid, EV sales

Fri, 24 Oct 2014

"As Prius represents by far the biggest chunk of the hybrid marketplace, where Prius goes, the segment goes," - Ed Kim, Autopacific

Fuel prices in the US have been tumbling for the last several weeks, with the average price of a gallon of gas at $3.120 as of October 20, according to the US Energy Information Administration. That price reflects a serious recent drop from $3.299 on October 6. Reports have even suggested that those low numbers might not change for a little while, perhaps as long as years. While drivers certainly love paying less at the pump, the change may be hurting the market for more fuel-efficient models, including the Toyota Prius.