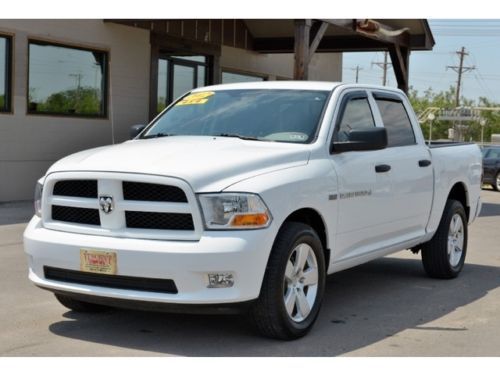

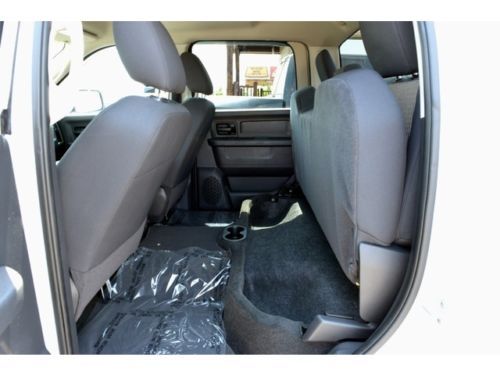

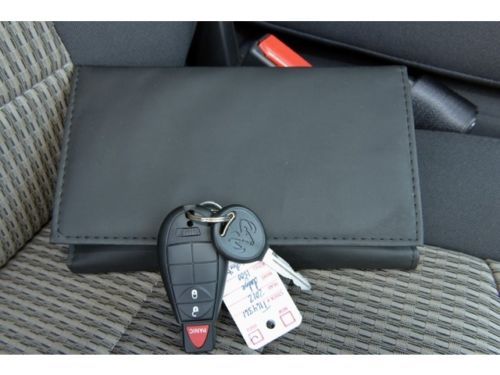

2012 Ram 1500 St Crew Cab 5.7 Hemi 4x4 Bedliner Warranty Low Miles V8 Tow Pkg Tx on 2040-cars

Abilene, Texas, United States

Ram 1500 for Sale

Ram 5.7 mega cab laramie longhorn 4x4 1500 winter is coming just serviced(US $38,977.00)

Ram 5.7 mega cab laramie longhorn 4x4 1500 winter is coming just serviced(US $38,977.00) 2013 laramie longhorn crew 4x4 navigation sunroof leather heated v8 hemi(US $43,701.00)

2013 laramie longhorn crew 4x4 navigation sunroof leather heated v8 hemi(US $43,701.00) 5.7l v8 hemi 22in rims navigation alpine bluetooth usb tonneau cover loaded

5.7l v8 hemi 22in rims navigation alpine bluetooth usb tonneau cover loaded 5.7l v8 hemi 4x4 slt lone star alpine sound touchscreen uconnect rdr rims camera

5.7l v8 hemi 4x4 slt lone star alpine sound touchscreen uconnect rdr rims camera 2014 laramie crew 4x4 navigation sunroof leather heated v8 hemi uconnect voice(US $43,137.00)

2014 laramie crew 4x4 navigation sunroof leather heated v8 hemi uconnect voice(US $43,137.00) Lifted 1 owner hemi 4x4 brand new lift, wheels and tires, ram box, moonroof, dvd

Lifted 1 owner hemi 4x4 brand new lift, wheels and tires, ram box, moonroof, dvd

Auto Services in Texas

XL Parts ★★★★★

XL Parts ★★★★★

Wyatt`s Towing ★★★★★

vehiclebrakework ★★★★★

V G Motors ★★★★★

Twin City Honda-Nissan ★★★★★

Auto blog

Ram recalls 30k trucks over faulty turn signals

Thu, 13 Jun 2013According to the National Highway Traffic Safety Administration, Chrysler is issuing a recall of 30,197 pickup trucks in the United States, all from the 2013 model year. The affected vehicles are the Ram 1500, 2500 and 3500, all of which were built between September 9, 2012 and March 5, 2013.

The problem affects models equipped with "optional premium taillamps," and according to NHTSA, the turn signal indicator "may not flash at a double rate to give a notification to the driver of a turn signal malfunction." The report states that if a driver is unaware of a problem with the turn signals and continues to use them as normal, other vehicles on the road may not be alerted that the vehicle is turning, which increases the risk of a crash.

Other recall woes have affected the Ram line recently. In April, we reported that Ram 1500 models were being recalled due to an improper adjustment of the parking brake cable, and several thousand Heavy Duty models were being called in for engine covers that do not have as much heat resistance as they're supposed to.

YouTube tallies votes for this year's top five Super Bowl spots [w/video]

Tue, 19 Feb 2013When we asked you to tell us which of this year's 16 car-themed Super Bowl commercials you liked best, you chose the Farmer commercial from Chrysler Group, advertising the Ram trucks, over Audi's Prom commercial in second place. Turns out the voters in YouTube's Ad Blitz poll agreed, voting the same commercial to the number one spot from among the field commercials in every category.

From there, however, they went in a totally different direction. Budweiser's The Clydesdales spot came second, Samsung's The Next Big Thing took third. The Jeep Whole Again ad scored fourth in the YouTube poll, fifth in our poll of auto commercials, and the Hyundai Team spot got fifth from the YouTubers, but ninth in our poll.

The voting results don't match up with the viewing numbers, though - while Farmer has more than 13 million views, The Next Big Thing is well beyond 21 million. You can read the press release below and see all five spots, lined up for you, one more time.

Chrysler and Hyundai join Pepsi and Coke as top Super Bowl spenders [w/ video]

Thu, 23 Jan 2014Super Bowl XLVIII is barely a week away, and some of the early ads are already leaking out. It's timely then that The Street has released rankings of the top five Super Bowl advertisers since 2009, showing Chrysler and Hyundai/Kia taking two of the spots with $131.7 million in cumulative spending.

Since 2010, the cost to air a 30-second Super Bowl ad has risen from $3 million in 2009 to about $4 million in 2014, and about a fifth of advertisers opt for a one-minute ad, which doubles costs. Last year, the ads brought in $292 million, and they have brought in roughly $2 billion since 2010.

Chrysler has spent $64.3 million since 2009 to make it the fourth highest spending company in the last five years. In that time, the company has rebranded itself as it emerged from bankruptcy with the Imported from Detroit ad campaign that premiered in 2011 and last year's God Made a Farmer Ram Trucks ad. Its 2012 Halftime in America sparked national debate about whether it was also a reference to the upcoming presidential election.