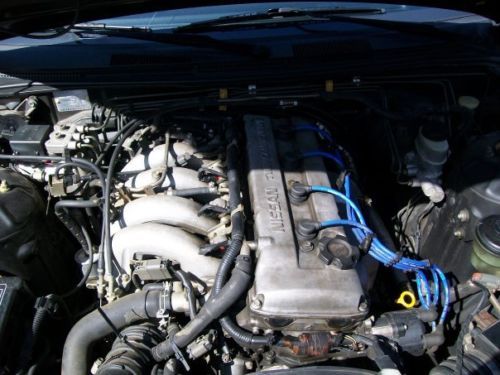

1995 Nissan S14 240sx Rolling Chassis. Sr20det Ls1 Drift S13 S15 Ae86 Nismo on 2040-cars

United States

Year: 1995

Trim: SE

Make: Nissan

Mileage: 165,000

Model: 240SX

Nissan 240SX for Sale

Auto blog

Nissan Juke to get higher-performance Nismo RC model

Tue, 22 Jan 2013It's hard to find more giggles for your crossover dollar than the Juke - regardless of how you feel about the way it looks, the singularly styled nichemobile from Nissan is very entertaining to drive. Yet we've always felt that the platform had more in it, and evidently its Japanese parent agrees, having recently bracketed the googly-eyed turbocharged CUV with a new Nismo model and the barking mad built-to-order Juke R. At present, neither the Juke Nismo or the GT-R-powered Juke R are sold in North America, but the former has already been confirmed for sale here.

Even when it does reach our shores, there will still be a heck of a lot of whitespace between the mild performance upgrades of the standard Nismo and the half-mill R model, and to hear the UK's Car tell it, Nissan has plans to plug that gap, too. According to its report, the automaker will shortly offer a Juke Nismo RC that will have roughly 20 horsepower more than the basic Nismo (which itself has 197 hp, nine more than the base Juke). The RC will apparently feature a lower, stiffer suspension, upgraded brakes and a unique exhaust and intake for a snarlier soundtrack. Both front-and all-wheel drive models are planned, as are manual and CVT transmission choices.

No word yet on the RC's pricing or even North American availability, but the regular-strength Juke Nismo is expected to arrive shortly, and Nissan is also said to have big plans for its performance nameplate, so we wouldn't rule it out.

Recharge Wrap-up: Nissan UK battery plant, Hyundai EV/FCEV station

Thu, Jan 21 2016Hyundai has opened a joint hydrogen fueling/EV charging station in South Korea. Called a "Fusion" station, it allows customers to take advantage of both types of alternative energy Hyundai uses for its vehicles. The station in Gwangju began as a hydrogen station, and EV charging capability was added recently. While users will have in common the use of green energy to power their vehicles, it will be interesting to see if spontaneous debates erupt between drivers over the merits of the two alternative powertrains. Hyundai will now use the hydrogen fueling part of the station to study fuel usage. Read more at Inside EVs. EV charging company EverCharge is teaming up with Schneider Electric to provide charging infrastructure to multi-tenant buildings. Because of the limited electricity for buildings like apartments, condominiums and offices – as well as the fact that multiple occupants often share power – installing charging at such locations has been challenging. EverCharge's SmartPower technology senses excess or limited power supply, and uses it to charge multiple vehicles accordingly. The groups will use this technology along with Schneider Electric's EVlink Home EV Charger to provide charging services at these otherwise difficult locations. Read more at Green Car Congress, or at the EverCharge blog. Nissan will build fourth-generation lithium-ion batteries for the Leaf at its plant in Sunderland, England. The announcement comes amidst rumors of the automaker outsourcing battery production. The decision means that Nissan's $37.5 million investment will preserve 300 jobs at the plant. The factory currently manufactures second-generation, 24-kW Leaf and e-NV200 batteries, and imports the third-generation, 30-kW Leaf battery from Nissan's plant in Smyrna, Tennessee. "Today's announcement reflects Nissan's intention to remain EV leaders for many years to come, with our European operations at the heart of our future innovations," says Nissan Europe Chairman Paul Willcox. Read more at Automotive News Europe, and in the press release below.

Nissan gives us the business on the art of clay modeling

Sat, 06 Apr 2013The team from The Dashboard recently stopped by the Nissan Technical Center in Japan for a look at what exactly goes into creating a full-scale clay model. While automakers have been using clay bucks for decades, designers and engineers are now combining computer renderings and hand-sculpted clay models to determine how a new vehicle will look in our world. Engineers use specially formulated clay kept warm in an oven to bring the body panels to life. They then coat the clay in a thin plastic film to add body color for the final look.

By the time everything is said and done, workers may have hundreds of hours in the model's creation. So, what happens when the company no longer needs the buck? They get scrapped. Someone comes in and dismantles the whole creation. We presume that action is set to the wailing tears of everyone who had a hand in building the model. Check out the video below for a closer look.

2040Cars.com © 2012-2025. All Rights Reserved.

Designated trademarks and brands are the property of their respective owners.

Use of this Web site constitutes acceptance of the 2040Cars User Agreement and Privacy Policy.

0.157 s, 7901 u

1995 nissan 240sx base coupe 2-door 2.4l

1995 nissan 240sx base coupe 2-door 2.4l 1989 nissan 240sx rb26dett

1989 nissan 240sx rb26dett 1990 nissan 240sx s13 automatic transmission ka24e bomber green

1990 nissan 240sx s13 automatic transmission ka24e bomber green 1995 nissan 240sx se coupe 2-door 2.4l

1995 nissan 240sx se coupe 2-door 2.4l Nissan 240sx se hatchback 2-door 2.4l

Nissan 240sx se hatchback 2-door 2.4l 1995 nissan 240sx coupe sr20det true sleeper

1995 nissan 240sx coupe sr20det true sleeper