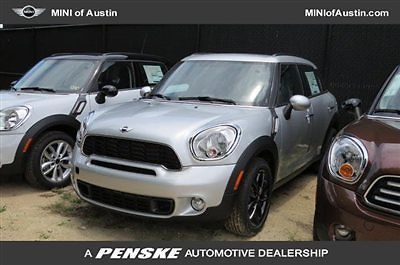

Mini Cooper Countryman Fwd 4dr S New Suv Automatic Gasoline 1.6l I-4 16v Dohc Tu on 2040-cars

MINI of Austin, 7113 McNeil Dr, Austin, TX 78729

Mini Countryman for Sale

Mini cooper countryman fwd 4dr s new suv manual gasoline 1.6l i-4 16v dohc turbo

Mini cooper countryman fwd 4dr s new suv manual gasoline 1.6l i-4 16v dohc turbo Mini cooper countryman fwd 4dr s new suv automatic gasoline 1.6l i-4 16v dohc tu

Mini cooper countryman fwd 4dr s new suv automatic gasoline 1.6l i-4 16v dohc tu Mini cooper countryman fwd 4dr new suv automatic gasoline 1.6l i-4 16v dohc true

Mini cooper countryman fwd 4dr new suv automatic gasoline 1.6l i-4 16v dohc true Mini cooper countryman fwd 4dr new suv manual gasoline 1.6l i-4 16v dohc lt wht

Mini cooper countryman fwd 4dr new suv manual gasoline 1.6l i-4 16v dohc lt wht Mini cooper countryman fwd 4dr new suv automatic gasoline 1.6l i-4 16v dohc bril

Mini cooper countryman fwd 4dr new suv automatic gasoline 1.6l i-4 16v dohc bril Fwd 4dr s mini cooper countryman s countryman new suv automatic gasoline 1.6l i-

Fwd 4dr s mini cooper countryman s countryman new suv automatic gasoline 1.6l i-

Auto blog

Mini fesses up to Countryman clutch issue, plans fix

Sat, 10 Nov 2012Aside from the general lack of snow in the Midwest earlier this year that hampered our ability to properly play with our Blizzak-equipped Mini Contryman long-term test vehicle, the biggest problem we had with this crossover during the year we spent with it was the transmission. On four different monthly updates (September, October, November and June), all in the hands of different Autoblog editors, the Countryman's clutch was called out for being too finicky, leading to many stall outs. Apparently, we weren't alone in our assessment of the Countryman's clutch woes.

According to MotoringFile, Mini has updated the Countryman with a different clutch material and improved software. This much-needed change is being implemented starting this month, but Mini hasn't said what it is doing about existing 2011 and 2012 Countryman models that are afflicted with this problem.

Head over to MotoringFile to see the full official statement from Mini USA on this issue.

Mini adding new driver assist systems to future models

Sun, 13 Oct 2013With all the recent news about automated vehicle technology (from Ford, Nissan and Toyota, among others), Mini is bringing some not-so-groundbreaking tech into its products to better keep the driver connected to the car. Other than stating that these new technologies will roll out in future models, there is no telling when we could see them starting to show up, although our best guess is the 2015 Mini Cooper.

Two of the more notable technologies that Mini will introduce include a head-up display system (shown above) and the "city braking" system to work in conjunction with collision warning and passenger detection. The automated braking system is made possible with the forward-mounted camera, which is also used for adaptive cruise control, auto-dimming headlights and a street sign detection system (to relay speed limit and traffic sign info to the driver). A new parking assist feature helps drivers find a properly sized parking spot, and then drivers can take advantage of the backup camera.

Mini obviously isn't the first to introduce these technologies, but it might be among the first to bring such a large number of advanced safety features into a car priced under $30,000 - though there is no telling how much these options will cost. The automaker has issued a brief press release for its upcoming driver assist systems, which is posted below.

Cargo ship carrying 1,200 Jaguars and Land Rovers deliberately run aground [w/video]

Mon, Jan 5 2015A cargo ship carrying a load of new cars out of Southampton has run aground in the English Channel in between England and the Isle of Wight. The vessel apparently suffered some sort of failure just 45 minutes after leaving port that caused it to list heavily to the starboard side before the crew deliberately beached it on Bramble Bank to prevent the ship from capsizing altogether. The vessel, called the Hoegh Osaka, is a 590-foot car carrier weighing some 57,000 tons and registered in Singapore. Although several automakers (including Honda and Bentley) were reportedly looking into whether they had cars on board, the vessel is said to have been filled to approximately one-third its capacity, with 1,400 vehicles on board – including 1,200 Jaguar and Land Rover vehicles, 65 Mini models and one Rolls-Royce Wraith. 70 to 80 pieces of construction equipment were also said to be on board. The Hoegh Osaka was en route from the southern British port of Southampton to Bremerhaven, Germany. Fortunately, no major injuries have been reported. The crew was mostly airlifted by helicopter off of the beached ship, with two crew members evacuated by lifeboat. One crew member reportedly jumped over 25 feet off the ship into the water before being immediately retrieved by rescue workers. According to the Daily Mail, two crew members were treated for non-life-threatening injuries, including a broken leg. It may take several days, if not longer, to extract the vessel from the sand bank and ascertain the damage to the ship and its cargo. An early attempt to free the ship with tugboats failed, meaning that the Maritime and Coastguard Agency may have to wait until more favorable high tides to try again before towing the ship back into the port. Bramble Bank, where the vessel was run aground, is a well-known obstacle to maritime navigators. The Queen Elizabeth 2 ran aground there in November 2008 with 1,700 passengers on board, but was quickly freed by four tugboats and was able to continue on its way. Two local yacht clubs also play a cricket match there every year at low tide. The vessel's operator, Hoegh Autoliners, praised the skill and quick thinking of the crew in acting to prevent the ship's capsizing by running her aground on the soft, sandy shoal. Watch the clip below for aerial footage of the beached ship, courtesy of the BBC. This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings.