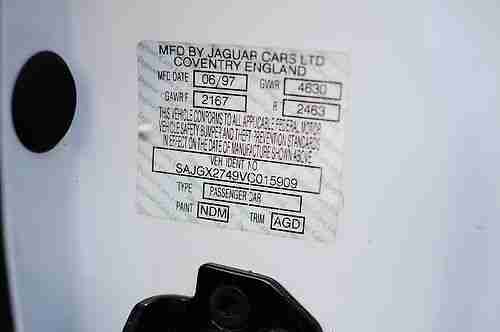

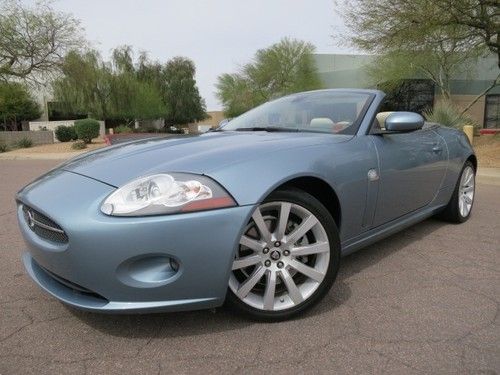

1997 Jaguar Xk8 Convertible on 2040-cars

New Smyrna Beach, Florida, United States

Body Type:Convertible

Vehicle Title:Clear

Engine:4.0L 3996CC 244Cu. In. V8 GAS DOHC Naturally Aspirated

Fuel Type:GAS

Make: Jaguar

Model: XK8

Trim: Base Convertible 2-Door

Safety Features: Anti-Lock Brakes, Driver Airbag, Passenger Airbag

Power Options: Air Conditioning, Cruise Control, Power Locks, Power Windows, Power Seats

Drive Type: RWD

Mileage: 36,200

Number of Doors: 2

Number of Cylinders: 8

Jaguar XK for Sale

Base coupe 4.2l nav cd 8 speakers am/fm in-dash 6-disc cd w/sirius satellite

Base coupe 4.2l nav cd 8 speakers am/fm in-dash 6-disc cd w/sirius satellite 2005 xk 4.2l v8 32v automatic convertible premium(US $22,991.00)

2005 xk 4.2l v8 32v automatic convertible premium(US $22,991.00) 1998 jaguar xk8 convertible new tires!(US $8,000.00)

1998 jaguar xk8 convertible new tires!(US $8,000.00) 2012 jaguar xkr coupe performance seat black pack low miles(US $79,888.00)

2012 jaguar xkr coupe performance seat black pack low miles(US $79,888.00) Stunning silver 2003 jag xk8 coupe 2-door 4.2l w/ $4000 niche 19" rims & z tires

Stunning silver 2003 jag xk8 coupe 2-door 4.2l w/ $4000 niche 19" rims & z tires Navigation alpine stereo heated seats pdc xenon alloy wheels like 05 06 08 09(US $32,950.00)

Navigation alpine stereo heated seats pdc xenon alloy wheels like 05 06 08 09(US $32,950.00)

Auto Services in Florida

Your Personal Mechanic ★★★★★

Xotic Dream Cars ★★★★★

Wilke`s General Automotive ★★★★★

Whitehead`s Automotive And Radiator Repairs ★★★★★

US Auto Body Shop ★★★★★

United Imports ★★★★★

Auto blog

Land Rover planning SVX hardcore off-roaders

Sun, May 3 2015The new Special Vehicle Operations division at Jaguar Land Rover has already given us an array of ultimate wheeled creations, but it isn't quite done yet. Next, according to Car and Driver, will be a new line of SVX models. Not to be confused with the Subaru coupe from the 1990s (which also had all-wheel drive, come to think of it), Land Rover's SVX models will be hardcore off-roaders. Details are few and far between at the moment, but they're said to take inspiration from rough-terrain events like the Dakar Rally and Camel Trophy as inspiration – different from the Ford F-150 Raptor that takes its cues from the Baja 1000. Last we heard, Land Rover was planning a hardcore Defender to send the model off to pasture in high-performance style, and considering an extreme Range Rover as well. If either of those rumors materialize, they look like they'd be prime candidates for the SVX line. JLR Special Vehicle Operations has already showcased what it can do with the high-performance Range Rover Sport SVR, the luxed-up Range Rover SVAutobiography, the exclusive F-Type Project 7 and the continuation classic Lightweight E-Type. C/D confirms that further SVR models are in store to replace Jaguar's R-S performance models, while the SVX line would likely remain exclusive to Land Rover.

Jaguar F-Type pitted against Porsche 911 Cabriolet by Tiff Needell

Wed, 24 Apr 2013You knew it wouldn't take long and it looks like EVO is first onto YouTube with a battle between the 2014 Jaguar F-Type and the 2013 Porsche 911. Tiff Needell spends a few laps warming up the tires (read: drifting like mad) in each droptop before getting in a timed run to see who's champion and who's second best.

Before the bell rings, its the Porsche that's got everything to lose, the 50-year-old era-defining sportscar getting on with a 3.4-liter flat-six, 350 horsepower, a seven-speed manual and a 3,197-pound curb weight. Other sportscars, like the F-Type, continue to eye the 911 like a flag atop Everest that they plan to first touch, and then rip from its socket. The mid-trim Jaguar rolls into the contest with a 3.0-liter supercharged V6 with 380 hp, an eight-speed automatic with paddle shifters and a curb weight of 3,521 pounds.

The video below shows you what happens when you let all those numbers fight it out on the same stretch of curvy track. Check it out.

Jaguar F-Pace V6 reminds us why we love supercharged engines

Fri, Oct 6 2017There are many things we like about our 2018 Jaguar F-Pace long-term car, as well as some things we don't care for, but easily one of the best things about it is the engine. Under the hood is the 380-horsepower supercharged V6 that Jaguar offers on other models. That amount of power would be fun in just about any car with any engine, but there are specific reasons why this particular engine is special, and it's because of that supercharger. Supercharged engines have a very different character than increasingly common turbo engines. One of the most noticeable differences being engine response. Unlike turbo engines, the F-Pace's V6 feels hardwired to your foot. Every extra millimeter of pedal travel yields a slightly greater amount of tug. And the tug is felt immediately. Even the best turbo engines have a hard time recreating this response. The power band is very linear, as well, so you know exactly what you're getting every time you hit the gas. The engine is wonderfully torquey, too. Because the Jaguar's engine uses a classic Roots-type blower, there's a major improvement in low-end torque. This means that our F-Pace has loads of grunt for punting around at low-rpm and can seriously move when tromping on the gas. And because of the near-instant throttle response and linear power band, it doesn't slam you in the back unexpectedly like some turbo engines do. Despite how great these supercharged engines are to experience, we're concerned that supercharged engines like this may disappear in all but ultra-limited production, high-performance cars such as the Chevy Corvette Z06 and Cadillac CTS-V. The reason being that car companies have to keep making cars more fuel efficient and lower emitting. Putting a supercharger on an engine is adding a handicap, since it takes engine power to spin the belt-driven supercharger. And when a turbo, which uses wasted energy from exhaust gas to spin the compressor and built boost, can effectively do the same thing, it's hard to make a case for a supercharger. We won't give up hope completely, though. Mazda is using superchargers on its spark-assisted compression ignition gasoline engines. And while we're not sure how powerful and sporty those will be, Mazda has said that it's going with superchargers for exactly the reasons we like the Jaguar engine: smooth power and fast throttle response.