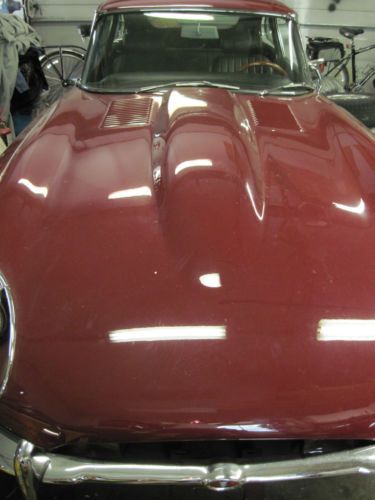

Impeccable Jaguar Xke Series Ii on 2040-cars

Park City, Utah, United States

|

This car is in impeccable conditions and was acquired from the original owner by the 2nd owner in 2013. The car was always stored in a heated storage garage in Salt Lake City, Utah. The original owner put approximately 80,000 miles on the car before having a ground up restoration done to the car by two well known restoration shops. The mechanicals were done by Jaguar Expert Walt Osborn of Vintage Jag Works presently in Blackfoot, Idaho and formerly of Salt Lake City. The cinnamon tan interior is perfect, but what was done to it is unknown, however the leather seats are original but in perfect condition, body & paint work was done by Troy Lundquist of Troy Lundquist Restorations, Sandy, Utah who has done work for many prominent people in Utah including John Huntsman. Per The Jaguar Daimler Heritage Trust Certificate included, it was originally Sable Brown and was changed to British Racing Green when it was restored. It was then driven approximately 4,000 miles before acquired by the 2nd owner who has driven it approximately 500 miles. As the car hadn't been driven for approximately 6 months the 2nd owner had the following work done in 2013: Radiator re-cored, new hoses installed, water pump replaced, speedometer rebuilt by Nisonger Instruments of NY, Carbs needles and seats installed to stop gas leaks, new battery terminals and hold down frame was installed. Original radio was repaired to accommodate an iPod with connector as parts were not able to be located for a full radio repair. The 4.2 Liter six cylinder engine was rebuilt and the pollution equipment removed and Triple SU side draft carburetors installed but it is unknown if they were on the car originally. It has a 4 speed synchromesh transmission that operates perfectly and was likely rebuilt during restoration. Included with the car are, a California interior car cover, 2 new clamp on side mirrors, the original owner’s manual, the original jack and case in perfect condition, lead hammer & knock off ring. All numbers were confirmed as matching per the JDHT Certificate & by a Jaguar expert as confirmed by his pictures that are available. The car drives perfectly even at high speeds. The tires although appear to be almost new and probably only have less than 5,000 miles on them are 10+ years old which is approximately when the restorations were completed. The five tires are mounted on 5 new stainless and chrome wire wheels and the spare has never been on the ground. The car was appraised by Pinnacle Car Appraisers in 2013 for over $70,000. It Won a Jaguar class award in August 2014 (3rd Place) at the Classic Sports Card Show in Park City, UT against stiff competition of many classic Jaguars from the Wasatch Mountain Jaguar Register, the Utah Chapter of the JCNA. 1st Place went to an off frame restored 1957 XK 140 DHC and 2nd Place went to an XKE OTS. |

Jaguar E-Type for Sale

Auto Services in Utah

Toyota & Lexus Repair Speclsts ★★★★★

Rand`s Auto Sales ★★★★★

No Crack Glass & Mirror ★★★★★

Montella`s Repair ★★★★★

Labrum Chevrolet Buick Inc. ★★★★★

Labrum Chevrolet Buick Inc. ★★★★★

Auto blog

2019 Jaguar I-Pace First Drive Review | The future is now

Wed, Jun 13 2018Jaguar's new all-electric I-Pace may be one of the brand's most significant breakthroughs. This is not just because the handsomely muscular all-wheel-drive crossover can travel 240 miles on a single charge to its 90 kWh battery. Or because it will cost a competitive $69,500 before federal and state incentives. Or that it can accelerate from 0-60 in 4.5 seconds — about as quickly as Jaguar's V8 F-Type sports car. It is not even because it may be the first vehicle to feature a small "froot" — "front boot" — which is a hideous British English term for the area known by the equally unappealing American neologism "frunk." The I-Pace ranks high in the Jag insurrective pantheon because it is the first truly competitive all-electric vehicle from a major luxury manufacturer to hit the entirety of the American market since Tesla jump-started (ugh!) the contemporary, fancy, battery-powered vehicle campaign back in 2008. Sure, Mercedes, Porsche, Audi, BMW, and others have promised these vehicles, but as far as we know, they don't exist, and we haven't driven them. The best news about the Big Electric Cat is that it's actually enjoyable on the road. Some of this is because of its intrinsic design benefits. The heavy battery pack, housed in the floor, contributes to a low center of gravity as well as ideal 50/50 front/rear mass balance. Both of these aid not only in the vehicle's road-holding capabilities, but in its style of holding the road. Jaguar has always been adept at splitting the suspension difference between German plank and American couch, and the I-Pace follows this general trend, providing a ride that is connected without feeling overly harsh, even on the optional 22-inch wheels and Pirelli P-Zero tires. (Note to self: Reserve the Instagram handle Donk-E.) But the I-Pace does something interesting. Due to its high seating position, and the low placement of its drivetrain components, it provides the sensation that the mechanical action of forward momentum is within the driver's direct and immediate control, but taking place elsewhere. There is no delay, or vagueness — the inputs are precise and it goes where you want and expect. But it induces the odd feeling that you are riding atop a maglev hovercraft. It's futuristic, uncanny, and fun.

Jaguar details XE for North America

Tue, Apr 28 2015Jaguar is bringing the XE to North America next spring, and in advance of its arrival, the British automaker is giving us more details on its new compact sports sedan. The top engine choice is dubbed the XE 35t, which is a little misleading since its tried-and-tested 3.0-liter V6 is actually supercharged, not turbocharged. Regardless of the manner of forced induction, its 340 horsepower and 332 pound-feet of torque are claimed to propel the XE to 60 miles per hour in 4.9 seconds on its way to an electronically limited top speed of 155 miles per hour. Buyers looking for something more frugal at the pump may be more interested in the other engine option. The XE 20d adopts Jaguar's new Ingenium diesel, a 2.0-liter turbocharged inline-four good for 180 hp and 318 lb-ft of torque. That's quoted for a 0-60 time of 7.4 seconds and a top speed of 140 mph. Both are mated to an eight-speed automatic transmission. All-wheel drive will also be available on both versions, but come by default in rear-drive form. Buyers will also have the choice among three trim levels, staring with Premium, moving up to Prestige and on to R-Sport with satin chrome and gloss black trim, a rear spoiler and 20-inch alloys. Pricing is set to be announced closer to launch, but for now you can scope out the details in the press release below, and watch this space for our upcoming drive report to follow our earlier report. JAGUAR XE ALL-NEW COMPACT SPORTS SEDAN TO EXPAND JAGUAR U.S. LINEUP IN 2016 - All-new Jaguar XE sports sedan to arrive in U.S.

Aston and Jag from James Bond Spectre have at it

Sun, May 3 2015Daniel Craig hasn't made a bad James Bond film yet. Spectre is his next step into the iconic role that's due to hit theaters on November 6, and it doesn't look likely to ruin his streak. Still, that's a long wait for such an exciting movie. If you're willing to possibly spoil just a little for yourself, a new featurette shows part of one of the big car chases right now. From what we've seen so far, the chase through Rome in Spectre has earned a good amount of screen time. While the reason for it in the plot is a mystery, that doesn't really matter anyway. What's important is that the scene stars Bond in the Aston Martin DB10 and a villain played by Dave Bautista in the now supercharged V8-powered version of the Jaguar C-X75 racing around the Italian capital's tight streets at night. This clip gives a glimpse at some of the work necessary to get the difficult filming completed. We've seen some of that effort before, though, when footage of the preparation for one shot leaked out. Craig reportedly sustained a pretty bad bump on the head during the shooting, and an earlier rumor also suggested that Bond might get behind the wheel of a Fiat 500 at some point in the scene.

1968 jaguar "e" type coupe 2 & 2

1968 jaguar "e" type coupe 2 & 2 1967 jaguar, series i, 4.2 liter e-type roadster

1967 jaguar, series i, 4.2 liter e-type roadster 1968 xke coupe series 1.5 vintage racer gunmetal/burgundy black numbers match

1968 xke coupe series 1.5 vintage racer gunmetal/burgundy black numbers match 1967 jaguar xke base 4.2l

1967 jaguar xke base 4.2l 1974 jaguar xke v12 series iii roadster/convertible

1974 jaguar xke v12 series iii roadster/convertible 1970 jaguar e-type

1970 jaguar e-type