2016 Honda Odyssey Ex-l on 2040-cars

Engine:6 Cylinder Engine

Fuel Type:Gasoline

Body Type:--

Transmission:Automatic

For Sale By:Dealer

VIN (Vehicle Identification Number): 5FNRL5H68GB068398

Mileage: 70984

Make: Honda

Trim: EX-L

Drive Type: FWD

Features: --

Power Options: --

Exterior Color: White

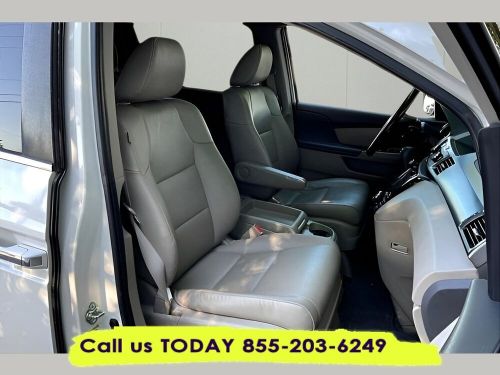

Interior Color: Gray

Warranty: Unspecified

Model: Odyssey

Honda Odyssey for Sale

2020 honda odyssey ex-l(US $28,999.00)

2020 honda odyssey ex-l(US $28,999.00) 2006 honda odyssey exl(US $1,400.00)

2006 honda odyssey exl(US $1,400.00) 2016 honda odyssey se(US $8,999.00)

2016 honda odyssey se(US $8,999.00) 2024 honda odyssey touring(US $47,889.00)

2024 honda odyssey touring(US $47,889.00) 2004 honda odyssey lx(US $3,500.00)

2004 honda odyssey lx(US $3,500.00) 2012 honda odyssey lx(US $6,700.00)

2012 honda odyssey lx(US $6,700.00)

Auto blog

Honda's Acura NSX masterstroke: building the factory in Ohio

Tue, Apr 12 2016When Honda announced it was going to build its NSX supercar in Ohio instead of Japan, it caught everybody in the industry by surprise. No one expected this proud Japanese company to build its most technologically advanced sports car anywhere but in its home country. Now Honda has a supercar production facility in rural Ohio that would be the envy of any Formula One team. The people at Honda call it the PMC, but its official name is the Performance Manufacturing Center. It's a building that started out as a shipping facility for suppliers, but Honda invested $70 million to transform it into a showcase facility that will build the NSX. Honda benchmarked the assembly operations at Ferrari, Lamborghini, McLaren, and Bentley before work began on its facility. The 200,000 square-foot building will also double as a customer reception center – Honda will open the doors for customers to come see their car being built. It's also going to offer them high-speed test drives at the gigantic Transportation Research Center just down the road. No one expected this proud Japanese company to build its most technologically advanced sports car anywhere but in its home country. Inside, the layout is wide open and well lit. There are no stripes or lines on the floor and none of the different departments are walled off. This creates a more welcoming appearance and lets you get a comprehensive view of the entire process at a glance. And with an eye towards future lessons learned, most of the equipment is of a modular design that can be easily reconfigured or moved. The body shop and paint shop are enclosed by glass walls so that anyone can see what's going on inside. And while you'll see some automation here and there, the idea was to achieve a blend between man and machine, not to try and automate everything. This is a low-volume facility with production targeted at only eight to ten cars a day. The plant runs four days a week with one ten-hour shift. Don't expect to see rows of new NSXs parked on any dealer's lot. The car will only be built to order. Honda is obsessed with ensuring the NSX is built to the most exacting quality standards. The plant people pored over the JD Power Appeal study to determine what supercar customers care about the most, then looked at which aspects of that directly tie into manufacturing. They developed their quality control strategy with three goals in mind. First, they wanted to build everything right the first time with no adjustments.

180,000 new vehicles are sitting, derailed by lack of transport trains

Wed, 21 May 2014If you're planning on buying a new car in the next month or so, you might want to pick from what's on the lot, because there could be a long wait for new vehicles from the factory. Locomotives continue to be in short supply in North America, and that's causing major delays for automakers trying to move assembled cars.

According to The Detroit News, there are about 180,000 new vehicles waiting to be transported by rail in North America at the moment. In a normal year, it would be about 69,000. The complications have been industry-wide. Toyota, General Motors, Honda and Ford all reported experiencing some delays, and Chrysler recently had hundreds of minivans sitting on the Detroit waterfront waiting to be shipped out.

The problem is twofold for automakers. First, the fracking boom in the Bakken oil field in the Plains and Canada is monopolizing many locomotives. Second, the long, harsh winter is still causing major delays in freight train travel. The bad weather forced trains to slow down and carry less weight, which caused a backup of goods to transport. The auto companies resorted to moving some vehicles by truck, which was a less efficient but necessary option.

Tier 1 suppliers call GM the worst OEM to work with

Mon, 12 May 2014Among automakers with a big US presence, General Motors is the worst to work for, according to a new survey from Tier 1 automotive suppliers, conducted by Planning Perspectives, Inc.

The Detroit-based manufacturer, which has been under fire following the ignition switch recall and its accompanying scandal, finished behind six other automakers with big US manufacturing operations. Suppliers had issues with trust and communications, as well as intellectual property protection. GM was also the least likely to allow suppliers to raise their prices in the face of unexpected increases in material cost, all of which contributed to 55 percent of suppliers saying their relationship with GM was "poor to very poor."

GM's cross-town competitors didn't fare much better. Chrysler finished in fifth place, ahead of GM and behind Dearborn-based Ford, which was passed for third place this year by Nissan. Toyota took the top marks, while Honda captured second place.