5-days *no Reserve* '12 Honda Insight Hybrid 1-owner Off Lease *great Mpg* on 2040-cars

Mount Juliet, Tennessee, United States

Honda Insight for Sale

Hybrid(US $4,450.00)

Hybrid(US $4,450.00) 2012 honda insight hybird****like new**only 4k miles(US $14,495.00)

2012 honda insight hybird****like new**only 4k miles(US $14,495.00) 2003 honda insight hybrid one owner low miles gas saver clean no reserve!!!

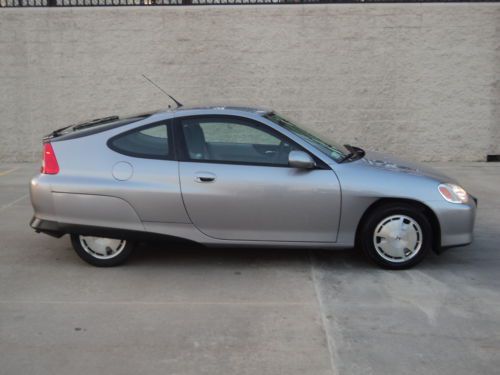

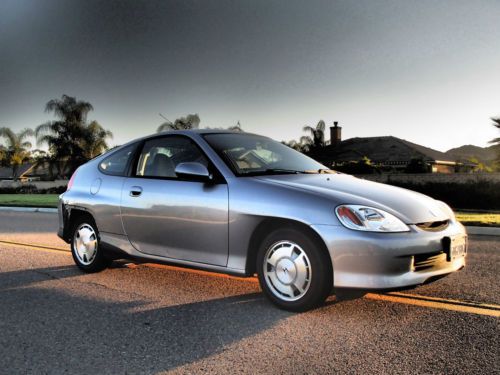

2003 honda insight hybrid one owner low miles gas saver clean no reserve!!! 2003 honda insight base hatchback 3-door 1.0l

2003 honda insight base hatchback 3-door 1.0l 2000 honda insight base hatchback 3-door 1.0l

2000 honda insight base hatchback 3-door 1.0l 4 dr sedan 1.3l sohc 8v hybrid polished metal metallic(US $14,398.00)

4 dr sedan 1.3l sohc 8v hybrid polished metal metallic(US $14,398.00)

Auto Services in Tennessee

Tri County Tires ★★★★★

Travis Auto Repair ★★★★★

Tindell G T Tire ★★★★★

Taylor`s Paint & Body ★★★★★

Stanley`s ★★★★★

Sport 4 Automotive Inc ★★★★★

Auto blog

Honda charged another $363 million over Takata airbags

Fri, Jun 12 2015The Takata airbag recall is growing increasingly expensive for Honda. In the latest hit to the automaker's bottom line, the company is revising the expected costs of its global safety campaigns by an additional 44.8 billion yen ($363 million) after the massive expansion in May. Months ago, Honda announced that it had set aside 50 billion yen ($425 million at the time) to meet the predicted expenses. According to Automotive News, due to the rather arcane laws of accounting, these new costs will actually be applied to the fiscal year that ended on March 31, rather than the current one. Honda's revised earnings will be announced in late June. The company previously reported an operating profit of 651.7 billion yen ($5.3 billion), which was down 13 percent from the previous year. There has been no change to planned dividends for investors. In the US, Honda and Acura have a total of about 6.28 million vehicles in need of a replacement airbag inflator, and the automaker says about two million of those are already repaired. In addition to the Takata campaign, the company has faced other financial setbacks during this calendar year. For example, in early January, it received a $70 million fine from the National Highway Traffic Safety Administration for failing to report 1,729 cases of injuries or deaths over 11 years. As part of a strategy to improve quality globally, Honda cut back its global sales forecasts for the coming year, and it also decided not to make any volume predictions through 2017. To: Shareholders of Honda Motor Co., Ltd. From: Honda Motor Co., Ltd. 1-1, Minami-Aoyama 2-chome, Minato-ku, 107-8556 Tokyo Takanobu Ito President and Representative Director Notice of Events after the Reporting Period Regarding Product Warranty Expenses Honda Motor Co., Ltd. (the "Company") and its consolidated subsidiaries have been conducting market-based measures in relation to airbag inflators, such as product recalls and a Safety Improvement Campaign. Due to factors arising since May 2015 such as an expansion of the scope of these market-based measures based on an agreement between our supplier and the U.S. National Highway Traffic Safety Administration, a change has arisen in the estimate relating to product warranty expenses. The amount of product warranty expenses now expected to be incurred is 44,800 million yen.

Honda favoring turbo over hybrid for US-market Vezel

Fri, 20 Dec 2013While Honda gears up to unveil the new Fit to the US market at the Detroit Auto Show next month, back in its home market, the car's crossover cousin is just going on sale. The Vezel was unveiled at the Tokyo Motor Show last month and already has a three-month waiting list in Japan, where Honda projects that 90 percent of customers will opt for the hybrid version. Not so in the United States, however.

When the Vezel reaches American showrooms, there'll be a number of key differences. For starters, it will carry a different name, though Honda isn't saying what that will be. For another, it will be built for North American consumption at Honda's new plant in Mexico, roughly half of whose production capacity is reportedly being allocated to the new crossover. And finally, it'll have a different engine.

In Japan the Vezel is being offered with a 1.5-liter four-cylinder engine, with or without electric assist. Honda won't offer the hybrid version here - at least not initially - but it is preparing to offer a turbo option. Although it has yet to announce US specifications and options, the 1.5-liter turbo four (also unveiled at the Tokyo show) is considered a stronger likelihood than the 1.0- or 2.0-liter versions.

Bisimoto 2014 Honda Odyssey packs 1,029 hp plus the kids

Wed, 06 Nov 2013You know, the last time I drove a Honda Odyssey, I thought, "Man, this thing could really use another 781 horsepower." Thank goodness for the folks at Bisimoto, then, who have brought this "Power-Van" to the 2013 SEMA Show in Las Vegas. It's your standard seven-passenger Honda Odyssey with massive powertrain tuning to deliver a full 1,029 horsepower. Honda has not listed the torque output, but we imagine it's roughly eleventy billion foot-pounds.

That crazy power bump has been achieved through the use of - *deep breath* - an Infinity ECU, Arias pistons, ARP headstuds and bolts, Bisimoto's own 360-degree oil cap, a cat-back exhaust system, stainless mufflers, an improved fuel pump, new spark plugs, custom headwork, R&R custom steel rods, Turbonetics BTZ7265 twin turbochargers, a wastegate, blowoff valve, VP racing fuels and a whole lot more. Honda says the only chassis/suspension modifications come in the way of Fifteen52 wheels, 225/30-series Toyo T1 Sport tires and Young Guns performance exhaust coatings. So as far as we can tell, this thing still uses a front-wheel-drive setup. I bet it'll do somersaults.

Of course, this is SEMA, where we assume there's a four-modification minimum for any car that enters the Las Vegas Convention Center, so the Odyssey has been given added visual flair, as well. Outside, that means there's a Denmatic design theme, a whole mess of Honda accessories (check out that roof tub) and some new paint. Inside, upgraded upholstery has been fitted, as have Recaro seats.