2012 Ford Mustang Shelby Gt500 Svt Cobra 6-speed 10 Mi Texas Direct Auto on 2040-cars

Stafford, Texas, United States

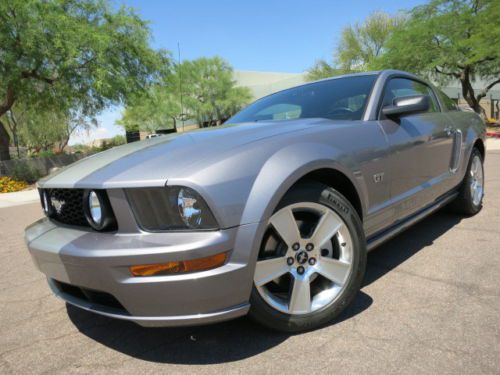

Ford Mustang for Sale

2010 ford mustang gt prem convertible 6-spd leather 35k texas direct auto(US $24,980.00)

2010 ford mustang gt prem convertible 6-spd leather 35k texas direct auto(US $24,980.00) Low 24k orig miles leather automaitc chrome whls rare color combo 04 05 07 08(US $16,950.00)

Low 24k orig miles leather automaitc chrome whls rare color combo 04 05 07 08(US $16,950.00) Ford mustang 1972 fastback w corbeau seat(US $12,500.00)

Ford mustang 1972 fastback w corbeau seat(US $12,500.00) 2010 ford mustang gt premium *loaded*(US $22,400.00)

2010 ford mustang gt premium *loaded*(US $22,400.00) 14 mustang, 3.7l v6, auto, leather, sport pack, alloys, spoiler, hid's, 1 owner!

14 mustang, 3.7l v6, auto, leather, sport pack, alloys, spoiler, hid's, 1 owner! 2009 gt ford mustang roush super charged 4.6l(US $40,000.00)

2009 gt ford mustang roush super charged 4.6l(US $40,000.00)

Auto Services in Texas

Youniversal Auto Care & Tire Center ★★★★★

Xtreme Window Tinting & Alarms ★★★★★

Vision Auto`s ★★★★★

Velocity Auto Care LLC ★★★★★

US Auto House ★★★★★

Unique Creations Paint & Body Shop Clinic ★★★★★

Auto blog

Want a V8 on the cheap? Buy a work truck

Thu, Aug 3 2017In case you didn't notice, V8 cars have gotten pretty expensive. If you want a modern muscle car like the Dodge Challenger R/T, Ford Mustang GT, or Chevy Camaro SS, you'll need between $34,000 and $38,000 for a stripped out example of one. The cheapest of those is the Challenger, and the priciest is the Camaro. These are also the cheapest V8 cars the companies offer. But if you absolutely have to have a V8 for less, there is an option, work trucks. As it turns out, all of the Big Three offer their most basic work trucks with V8s. And because they're so basic, they're pretty affordable, especially when sticking with the standard two-wheel drive. A Ram 1500 Tradesman with a V8 can be had for as little as $29,840, which is a little more than $4,000 less than a Challenger R/T. For a bit more at $30,275, you can have a Chevy Silverado W/T, almost $8,000 less than a Camaro SS. The most expensive is the V8 Ford F-150 starts at a starting price of $30,670, which is a bit over $5,000 less than the Mustang. Of course you'll be in an ultra bare bones vehicle with few comforts, and the price will go up if you add stuff, but we're bargain hunting here, and sacrifices are sometimes necessary. Besides, what you lose in comfort, you gain in loads of cargo space and towing (try to look at the bright side). Also, as a side note, all three trucks are available with optional electronic locking rear differentials. At the discounted price of these trucks, you still get a heaping helping of power. The most potent of the trio is the Ram 1500 Tradesman with 395 horsepower and 410 pound-feet of torque generated by a 5.7-liter V8. Compared with the Challenger R/T, the Ram is up by 20 horsepower and they're tied for torque. The value proposition is even more stark between the two vehicles when looking at the price per horsepower. Each pony in the Ram costs $75.54, while the Challenger charges you $90.91. The Challenger is also more expensive per horsepower than its close competitors. The F-150's 5.0-liter V8 is just barely behind the Ram with 395 horsepower and 400 pound-feet of torque. That's still more power than the Challenger, and it matches the torque of the 2017 Mustang GT. On the down side, it still would be down 20 horsepower on that same 2017 Mustang, and it's behind by 60 horsepower and 20 pound-feet on the new 2018 Mustang GT. The F-150 also just edges out the Mustang in the dollar per horsepower measure.

Quitting Mexico factory helps bring down Ford earnings $200 million in 2016

Thu, Jan 26 2017Ford released its 2016 earnings report this morning, and despite a fourth quarter net loss it proved to be the automaker's second most successful year ever, following record breaking numbers in 2015. Losses for the year come from a number of sources, including accounting changes and a $200 million hit for backing out of the small-car factory in San Luis Potosi, Mexico. Despite the loss, come March 9 about 56,000 UAW-represented employees will receive a $9,000 profit-sharing check. That, like most of Ford's other 2016 metrics, is slightly down from the year before, but it's still the second best profit-sharing payment ever. Total net income was $4.6 billion, down $2.8 billion from 2015. Total revenue for 2016 was $151.8 billion, up $2.2 billion. Ford's earnings report lists a global market share of 7.6 percent, down a tenth from 2015. Ford's European and Asia-Pacific markets posted their best and second best pre-tax profits respectively. The South American, Middle East, and African markets all took hits because of unstable economies and other external factors. Ford expects to have another down year in 2017 as it invests in new and emerging markets and focuses more on its mobility projects.Related Video: This content is hosted by a third party. To view it, please update your privacy preferences. Manage Settings. News Source: Ford via Automotive NewsImage Credit: Getty Earnings/Financials Plants/Manufacturing UAW/Unions Ford Lincoln Mexico ford earnings

Entry-level F-150 now offers SuperCrew, Sport Package

Thu, 29 Aug 2013Ford has made a few notable tweaks to the lower end of its F-150 lineup, giving customers a more affordable version of the four-door SuperCrew body style. The popular SuperCrew could previously only be had on XLT models and above, but Ford has announced that 2014 F-150s with the base STX trim can get the more versatile body.

The STX SuperCrew brings the price of a four-door F-150 down from $34,525 to $33,145. Like the XLT SuperCrew, the STX will be available with the choice of a 5.5- or 6.5-foot bed, while a 5.0-liter V8 can replace the base 3.7-liter V6 for $4,425. Ford has not released pricing on the different bed lengths yet, but opting for the 6.5-foot bed on the XLT raises the price $1,240 and forces buyers into the 5.0-liter V8. We'd expect a similar arrangement on the STX.

The other big news for fans of affordable pickups is the addition of an STX Sport Package on the base-level truck. It adds 20-inch wheels, black exterior accents, black-and-gray cloth seats and decals on the truck's box. The Sport Package is available on all three of the STX's body styles, with Ford listing the price as $980 with current discounts.