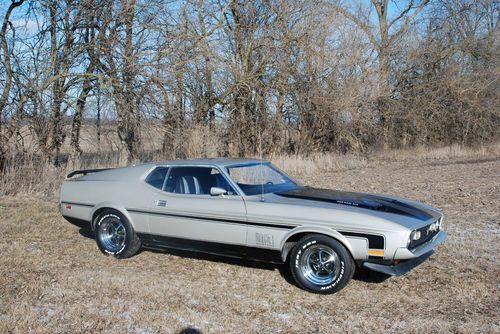

1971 Ford Mustang Mach 1 429 J Code Super Rare 1 Of Only 815 Cobra Jet Mustangs on 2040-cars

Naperville, Illinois, United States

Engine:BIG BLOCK 429

Body Type:Coupe

Vehicle Title:Clear

For Sale By:Dealer

Interior Color: Black

Model: Mustang

Number of Cylinders: 8

Trim: Mach 1 BIG BLOCK 429

Drive Type: rear

Mileage: 75,000

Exterior Color: Silver

Ford Mustang for Sale

Auto Services in Illinois

Yukikaze Auto Inc ★★★★★

Woodworth Automotive ★★★★★

Vogler Ford Collision Center ★★★★★

Ultimate Exhaust ★★★★★

Twin Automotive & Transmission ★★★★★

Trac Automotive ★★★★★

Auto blog

Ringbrothers shows off Coyote-powered 1968 Mercury Cougar

Thu, Feb 25 2021We'll openly admit that not every SEMA build is our cup of tea. But this? A tastefully resto-modded 1968 Mercury Cougar with a 460-horsepower Ford Mustang V8? Yeah, this is right in our wheelhouse. Sadly, there was no in-pwerson SEMA show in 2020, so we missed out on gems like this one. SEMA or no SEMA, the aftermarket carries on, and co-owners Jim and Mike Ring of Ringbrothers (get it?) saw no reason to let their time and effort go to waste. When they're not building wild customs (see: 1,100-horsepower 1972 AMC Javelin AMX) or more subtle showcases (such as this Cougar or their 1971 K5 Chevy Blazer build from 2018), the folks at Ringbrothers crank out factory reproduction parts, whether for old-fashioned restoration or modification purposes. While '60s muscle cars are recurring build subjects for the two, the Cougar was the first of its kind they tackled. Keeping it in the family, Ringbrothers sourced a Ford 5.0-liter "Coyote" V8 and a 10-Speed Automatic (lifted from an F-150 Raptor, incidentally) for the build. They didn't stop with the driveline, of course. The suspension was overhauled with a little help from DSE and a set of HRE Series C1 C103 Forged 3-Piece wheels were thrown over upgraded brakes. "We put our heart into each car we build, and this Cougar is no exception," Jim said. "The finished product is mild and classy, yet any enthusiast instantly knows it's not stock. I imagine this is what Mercury designers would have come up with if they were building the Cougar today." "While we couldn't bring the car to the SEMA Show, we hope it can be shown to the public soon," Mike said. "We had never done a Cougar before, so this was a fun build. I love working with new shapes and coming up with new ideas." There's plenty to appreciate about this Cougar apart from the mechanicals, too. The finish is Augusta Green Metallic (courtesy of BASF), which was a factory color in 1968. You may know it by another name: Highland Green. There are a few custom exterior touches, but they're quite subtle and styled to be period-correct. The interior was also restored and updated, and it's where you'll find the only thing we're not fond of: that big, fat truck shifter. Gearbox choices notwithstanding, it's a bit of an eyesore. But considering how gorgeous the rest is, we'll give it a pass. Related Video:

How Ford switched gears for the all-new F-150

Fri, Mar 6 2015Editor's Note: This story is authored by Julia Halewicz, a senior editor with AOL's Custom Solutions Group. She holds a Masters in Journalism from NYU and has spent her career as an editor of various newspapers, magazines and digital outlets. Last year on the Friday before Labor Day, the 2014 Ford F-150 pickup truck came off the Dearborn assembly line for the last time. After the last seam was welded, the F-150 that had been so beloved by American consumers would begin the transition from traditional steel manufacturing to an aluminum body, and the second phase of Ford's 2007 blueprint for sustainability would begin. Jobs would be created, and Ford would deliver a stronger product to its consumers. It was a moment Ford would call the biggest in the company's 111-year history. Breaking The Mold For some, the change was almost unfathomable. How could a truck be made with aluminum, and why change what clearly was working very well for the company? "We have a saying at Ford that leaders lead," said Doug Scott, the company's truck group marketing manager. "This was an ideal product to make with aluminum-alloy, because lightweighting made so much sense for a truck, because the extent to which you could take weight out of a truck, you could add more value to the customer in terms of more towing, more payload, more durability, more efficiency – so again all this required us to be out in front further out in front that we normally would be to make sure that we would deliver on all those expectations." Ford began the planning process about five years before the first aluminum F-150 would come to market. The company had a lot of questions. What was customer acceptance of aluminum, could they build the truck, and could the truck be repaired out in the field? Finally, Ford needed to determine if there were enough materials available to support the demand for the F-Series. Aluminum vehicles aren't unusual, but had never been built on the scale of the F-150 – approximately one every minute. Ford created two prototypes to determine if the product would meet and exceed consumer expectations. Any change to the vehicle had to be justified in performance, safety and economy. An aluminum truck needed to be safer, lighter, have increased payload, haul more, and have improved fuel efficiency. After driving the prototypes, Ford knew it was ready to move forward. Once the aluminum truck was ready to build, the next challenge was quickly transforming the plant.

Ford investing $500M in engine plant for 2.7L EcoBoost production

Sun, 30 Mar 2014Ohio is a hot area for Ford at the moment with the announcement just a few weeks ago that production of the next-generation F-650/F-750 medium-duty trucks would move from Mexico to the Ohio Assembly Plant in Avon Lake, Ohio. Now, Ford is investing $500 million to hire 300 workers at its Lima Engine Plant in Lima, Ohio, to add production of the twin-turbo 2.7-liter EcoBoost V6 for the 2015 F-150.

The latest investment will be used to add a new flexible engine assembly system and renovate 700,000 square feet of the plant for machining and assembly areas. The Lima factory already builds Ford's 3.5-liter and 3.7-liter Duratec V6 engines. The plant opened in 1957, and it's on track to build its 40 millionth engine later this year.

Ford claims that the 2.7-liter EcoBoost will offer V8 performance with better efficiency in the F-150. It comes standard with intelligent stop/start that doesn't activate when the truck is towing or in four-wheel drive, and it's made from a combination of compacted graphite iron and aluminum for low weight and high strength. The company says that V6 engines have already proven popular in the F-150 with 57 percent of trucks in 2014 being equipped with either the naturally aspirated 3.7-liter or turbocharged 3.5-liter EcoBoost engines.

2005 ford mustang v6 convertable

2005 ford mustang v6 convertable 1995 mustang cobra r

1995 mustang cobra r 2008 mustang gt grabber orange low miles

2008 mustang gt grabber orange low miles 2007(07)mustang v6 silver/black spoiler must see ! save huge!!!

2007(07)mustang v6 silver/black spoiler must see ! save huge!!! Custom 1996 ford mustang silver metal flake paint new interior new tires

Custom 1996 ford mustang silver metal flake paint new interior new tires Ford mustang roush stage 1 low miles

Ford mustang roush stage 1 low miles