1965 Ford Galaxie Custom Ex. Possible Police Car Project Car With No Reserve on 2040-cars

High Point, North Carolina, United States

Engine:5.8L 5769CC 352Cu. In. V8 GAS OHV Naturally Aspirated

Body Type:U/K

Vehicle Title:Clear

Fuel Type:GAS

Exterior Color: White

Make: Ford

Interior Color: Red

Model: Galaxie

Number of Cylinders: 8

Trim: Base

Drive Type: U/K

Mileage: 150,555

Up for sale today is what I believe to be an ex police/govt official cruiser 1965 Ford Galaxie 500. No guarantees are made, however, as I am just reading what a vin decoder is telling me. I don't see any markings on the vehicle other than the 352 fender emblems, but it does still have the spotlight and according to the Vin decoder it used to have the 352 4 bbl 250hp version. Here is what I found it to say:

| 5 | Year | 1965 |

|---|---|---|

| A | Assembly | Atlanta, GA |

| 54 | Body | Custom 4-Door Sedan |

| X | Engine | 8 Cyl. 352 CID Horsepower: 250 Carbs: 1-4BBL Compression: 9.3:1 |

| 204070 | Serial | 204070 |

Ford Galaxie for Sale

1967 ford galaxie 500 fastback project car no reserve

1967 ford galaxie 500 fastback project car no reserve 1968 ford galaxie 500 convertible 390(US $6,500.00)

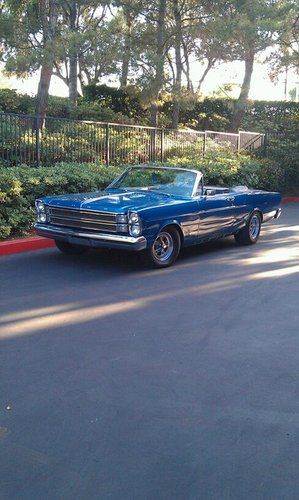

1968 ford galaxie 500 convertible 390(US $6,500.00) 1965 ford galaxie convertible

1965 ford galaxie convertible 1968 ford galaxy conv. nr. not chevy/gm/dodge/amc/mopar

1968 ford galaxy conv. nr. not chevy/gm/dodge/amc/mopar 1966 ford galaxie convertable(US $7,000.00)

1966 ford galaxie convertable(US $7,000.00) 1963 ford galaxie 500 frame off restoration 390, 4 speed, 2 videos

1963 ford galaxie 500 frame off restoration 390, 4 speed, 2 videos

Auto Services in North Carolina

Walkertown Tire Service ★★★★★

Victory Tire & Auto Svc ★★★★★

Valvoline Instant Oil Change ★★★★★

USA Paint & Body ★★★★★

Truth Automotive-Transmission ★★★★★

Triangle Window Tinting ★★★★★

Auto blog

Ford hybrid sales rebound following MPG controversy

Sun, 31 Aug 2014Ford hybrid customers apparently have very short memories. With two EPA fuel economy reratings in the last year, sales of the C-Max, Fusion Hybrid and Lincoln MKZ haven't been too terribly dented, Ward's Auto reports.

All three vehicles saw sales dips following the August 2013 rerating, although sales of the MKZ Hybrid had begun to rebound as early as November of that year. C-Max sales, meanwhile, took slightly longer, with sales on a steadily improving course as early as February of this year.

The second rerating, in June of this year, has had an even smaller effect on the Blue Oval's hybrids. The C-Max has actually been subject to a sales increase, while both the MKZ and Fusion saw minor sales drops (less than 400 units between the two in the month following the rerating).

Weekly Recap: An '80s encore in the auto world

Sat, Jul 11 2015The '80s returned in a big way this week, as National Lampoon's, Ghostbusters, Miami Vice, and even Tetris were back in the news. While there were far more serious topics (see below), nostalgia mingled with modern marketing to put these Reagan-era favorites back in the spotlight. The '80s were alternately cold and corny at times, but their cultural touchstones can still generate big money. That's why Infiniti recreated an iconic scene from National Lampoon's Vacation (1983) for an advertisement that hawks the QX60 crossover. Actor Ethan Embry, who played Rusty Griswold in a later Lampoon's movie, pilots the Infiniti – which is serving as a modern Family Truckster – for a trip to Walley World. A blonde pulls alongside in a red Lamborghini. They flirt, and she drives on. Christie Brinkley, who played the original girl in the red sports car (she drove a Ferrari in the '83 flick), is riding shotgun and chides Embry with: "A blonde. In a convertible. Seriously?" Okay, it's hardly on the level of "here's looking at you," or even "you can't handle the truth," but it should resonate with '80s babies, many of whom are now having children of their own and moving into three-row SUVs like the QX60. Naturally, Hollywood is going back to the well, too, with a Vacation remake that premiers July 29. Meanwhile, Ghostbusters is returning next year, and director Paul Feig offered a peak at the new Eco-1 in this tweet. In the 1984 classic, the team drove a modified 1959 Cadillac. Now, it will drive a late '80s Cadillac. As expected, the announcement generated support and controversy from movie and car enthusiasts. His tweet had generated several thousand retweets and favorites in the days following the news. Though the '80s Caddy looks, uh, less elegant in comparison to the now-iconic fins and curves of the original Ecto-1, it's about the same time lapse into the past as the '59 Caddy was to viewers in 1984. Speaking of 1984, Miami Vice, which debuted that year on NBC, is seeing one of its hero cars hit the auction block, Mecum Auctions announced this week. The 1986 Ferrari used on the show will be offered for sale Aug. 15 during Monterey classic car week. The white supercar runs a 390-hp flat 12-cylinder engine paired with a five-speed manual transmission and was in storage after the show ended in 1989 until earlier this year. It has 16,124 miles on the odometer and is authenticated by Ferrari North America and Classiche.

Editors’ Picks October 2022 | Electric trucks and some excellent SUVs

Wed, Nov 2 2022This month sees a bevy of totally new or totally redesigned cars gain Editors’ Pick status. Important EVs like the F-150 Lightning and GMC Hummer EV quickly jump into the list, and they do so with authority, as all our editors love these trucks. The Range Rover is always a superb experience, and this generation proves to be no different. Plus, the new generation of Kia Sportage continues to surprise and impress. In case you missed our previous Editors' Picks posts, hereÂ’s a quick refresher on whatÂ’s going on here. We rate all the new cars we drive with a 1-10 score. Cars that are exemplary in their respective segments get EditorsÂ’ Pick status. Those are the ones weÂ’d recommend to our friends, family and anybody whoÂ’s curious and asks the question. The list that youÂ’ll find below consists of every car we rated in October that earned an EditorsÂ’ Pick. 2022 GMC Hummer EV The Four-Wheel-Steer system lets the 2022 GMC HUMMER EV Pickup m View 17 Photos Quick take: The Hummer amazes as an electric supertruck with its wild acceleration, incredible off-road capability, luxuriousness and epic utility. It's far from a "green" eco-friendly vehicle, but that's not the point of this technological powerhouse. Score: 8.5 What it competes with: Rivian R1T, Ford F-150 Raptor R, Ram 1500 TRX Pros: Stupid quick, tons of tech, off-road capability in spades Cons: Not efficient, annoying in tight spaces, price From the editors: Road Test Editor Zac Palmer — "I don't think I've driven a more ridiculous vehicle this year, but that's sort of the point with the Hummer. There's a great argument against this sort of EV in that it doesn't live up to being an efficient and planet-friendly vehicle, but hey, that's not the point. The Hummer EV is a supertruck and wild technological masterpiece for off-roading in the same way that a mid-engine supercar is to track performance. It's not meant to be the EV everybody drives to work and back (mostly because few can afford it), but it serves as a line in the sand of what can be done with electric off-road trucks. This pickup rules, and if you can afford one, you're going to love it." Senior Editor, Green John Beltz Snyder — "This Hummer revival is a showcase of technology and capability on the part of GM, making it an absolute blast to drive and a joy to use.