67 1967 Dodge Dart Gt Super Clean V-8 Chrysler Mopar on 2040-cars

Lenexa, Kansas, United States

Dodge Dart for Sale

1972 dodge dart demon -- documented by a broadcast sheet with correct code(US $19,800.00)

1972 dodge dart demon -- documented by a broadcast sheet with correct code(US $19,800.00) Completely restored runs and drives like new cruiser classic mopar not 340

Completely restored runs and drives like new cruiser classic mopar not 340 2013 dodge dart limited sedan 4-door 2.0l(US $21,300.00)

2013 dodge dart limited sedan 4-door 2.0l(US $21,300.00) 1968 dodge dart 4 door sedan(US $1,800.00)

1968 dodge dart 4 door sedan(US $1,800.00) 2014 aero new turbo 1.4l i4 16v automatic fwd sedan

2014 aero new turbo 1.4l i4 16v automatic fwd sedan 2013 dodge dart rallye turbo 6-speed nav rear cam 19k!! texas direct auto(US $16,980.00)

2013 dodge dart rallye turbo 6-speed nav rear cam 19k!! texas direct auto(US $16,980.00)

Auto Services in Kansas

Ussery Auto Body Repair Inc ★★★★★

Schoonover`s Auto Repair ★★★★★

Raytown Skelly Service ★★★★★

Pdi Clear Bra ★★★★★

Mike`s Car Care Center ★★★★★

Midwest Tinting ★★★★★

Auto blog

Stellantis announces ‘Circular Economy’ business to drive revenue, decarbonization

Tue, Oct 11 2022Stellantis has already announced its plans to reach net-zero carbon emissions by 2038. Today, the automaker has announced a new business unit to help it reach that goal while generating 2 billion euros per year in revenue by 2030. The “Circular Economy” business will help make revenue less dependent on finite, rare and ecologically problematic materials. The Circular Economy model features what Stellantis calls a “4R” strategy, comprising remanufacturing, repair, reuse and recycling. The goal is to make materials last as long as they can, reducing reliance on the acquisition of those precious new materials in the future by returning them to the business loop when theyÂ’ve reached the end of their first life. Through these processes, Stellantis says it can save up to 80% raw material and 50% energy compared to manufacturing a new part. Remanufacturing, or “reman” in Stellantis shorthand, means dismantling, cleaning and rebuilding parts to OEM spec. Nearly 12,000 remanufactured parts are available for customers to purchase. Some remanufacturing is done in-house, and some with partners and through joint ventures. Repair is pretty obvious — fixing parts to put back into vehicles. This also consists of reconditioning, to make a vehicle feel like new. Stellantis boasts 21 “e-repair” centers for repairing electric vehicle batteries. Reuse refers to parts still in good condition from end-of-life vehicles sold as-is. Stellantis says it has 4.5 million multi-brand parts in inventory. These are sold in 155 countries through the B-Parts e-commerce platform. Reuse also refers second-life options, such as using batteries outside of automotive purposes. Recycling involves dismantling parts and scraps back into raw material form that is then looped back into the manufacturing process. Stellantis says it has collected 1 million parts for recycling in the past six months. Recycling doesnÂ’t get counted in that aforementioned 2 billion euros of revenue, but it does save the company money on acquisition of raw materials. As for batteries, specifically, Stellantis expects this recycling business to ramp up after 2030, when the packs currently in service begin to reach the end of their lifecycle. Stellantis will use its new “SUSTAINera” label to denote parts that are offered as part of its Circular Economy business.

Stellantis invests more than $100 million in California lithium project

Thu, Aug 17 2023Stellantis said it would invest more than $100 million in California's Controlled Thermal Resources, its latest bet on the direct lithium extraction (DLE) sector amid the global hunt for new sources of the electric vehicle battery metal. The investment by the Chrysler and Jeep parent announced on Thursday comes as the green energy transition and U.S. Inflation Reduction Act have fueled concerns that supplies of lithium and other materials may fall short of strong demand forecasts. DLE technologies vary, but each aims to mechanically filter lithium from salty brine deposits and thus avoid the need for open pit mines or large evaporation ponds, the two most common but environmentally challenging ways to extract the battery metal. Stellantis, which has said half of its fleet will be electric by 2030, also agreed to nearly triple the amount of lithium it will buy from Controlled Thermal, boosting a previous order to 65,000 metric tons annually for at least 10 years, starting in 2027. "This is a significant investment and goes a long way toward developing this key project," Controlled Thermal CEO Rod Colwell said in an interview. The company plans to spend more than $1 billion to separate lithium from superhot geothermal brines extracted from beneath California's Salton Sea after flashing steam off those brines to spin turbines that will produce electricity starting next year. That renewable power is expected to cut the amount of carbon emitted during lithium production. Rival Berkshire Hathaway has struggled to produce lithium from the same area given large concentrations of silica in the brine that can form glass when cooled, clogging pipes. Colwell said a $65 million facility recently installed by Controlled Thermal can remove that silica and other unwanted metals. DLE equipment licensed from Koch Industries would then remove the lithium. "We're very happy with the equipment," he said. "We're going to deliver. There's just no doubt about it." Stellantis CEO Carlos Tavares called the Controlled Thermal partnership "an important step in our care for our customers and our planet as we work to provide clean, safe and affordable mobility." Both companies declined to provide the specific investment amount. Controlled Thermal aims to obtain final permits by October and start construction of a commercial lithium plant soon thereafter, Colwell said. Goldman Sachs is leading the search for additional debt and equity financing, he added.

Dodge engineers trying to shoehorn Pentastar into Dart?

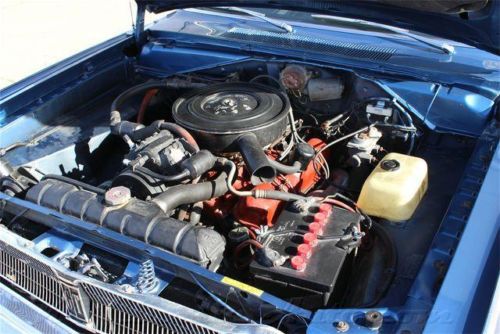

Tue, 19 Nov 2013The fact that the Dart's launch has been a pretty dismal affair isn't what we'd call secret. Judging by its mounting inventories and poor critical reception, Dodge's successor to its unloved Caliber has struggled since it hit the market. And while both of those are difficult problems to address, at least their cause is well known - the powertrain.

Even Fiat-Chrysler CEO Sergio Marchionne has acknowledged that the powertrain options in the Dart are substandard, admitting at January's Detroit Auto Show that the powertrains are "less than ideal." Leading with the 1.4-liter turbocharged four-cylinder found in the Fiat 500 Abarth left a bad taste in the mouths of consumers thanks to the laggy engine and dead throttle response (to say nothing of the manual and dual-clutch gearboxes that needed more refinement). The addition of the 184-horsepower 2.4-liter Tigershark in the Dart GT has helped matters some, but apparently Auburn Hills doesn't think it's quite enough.

If rumors are to be believed - get that salt ready - a possible solution may be in the works. A report from Allpar is claiming that Dodge is considering fitting a Pentastar V6 into the Dart's engine bay. As the Mopar-obsessed website points out, the critically acclaimed Pentastar is available in three different sizes - 3.0 liters, 3.2 liters and the original 3.6 liters. We don't get the 3.0 here in the US, but the 3.2 can be found in the new Jeep Cherokee and the 3.6 has been seemingly fitted to every model Chrysler can shoehorn it into.