1969 Chevelle Malibu Convertible 350/350 12 Bolt 56k on 2040-cars

Oregon City, Oregon, United States

Body Type:Convertible

Engine:350

Vehicle Title:Clear

Fuel Type:Gasoline

For Sale By:Private Seller

Number of Cylinders: 8

Make: Chevrolet

Model: Chevelle

Trim: Malibu

Warranty: Unspecified

Drive Type: 350 12 bolt Limited slip

Options: Convertible

Mileage: 56,780

Exterior Color: Blue

Interior Color: Black

Chevrolet Chevelle for Sale

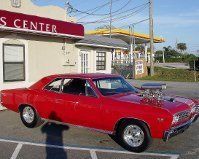

1970 chevelle pro street, pro touring station wagon(US $13,500.00)

1970 chevelle pro street, pro touring station wagon(US $13,500.00) 1969 chevrolet chevelle low miles, restored (we export)

1969 chevrolet chevelle low miles, restored (we export) 1972 chevelle. runs great! extra parts included!

1972 chevelle. runs great! extra parts included! Nearly rust free 1965 chevelle,alot of car for the money(US $5,700.00)

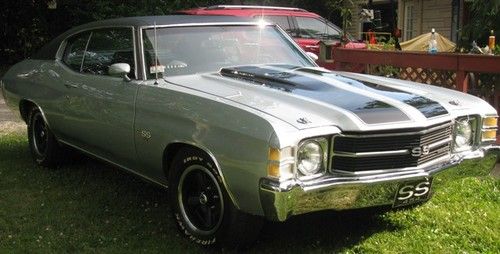

Nearly rust free 1965 chevelle,alot of car for the money(US $5,700.00) 1971 chevelle ss 454 correct & documented, 1971 ls-7 crate motor, 4-spd(US $42,500.00)

1971 chevelle ss 454 correct & documented, 1971 ls-7 crate motor, 4-spd(US $42,500.00) Blown 632 chevelle ss(US $50,000.00)

Blown 632 chevelle ss(US $50,000.00)

Auto Services in Oregon

Tualatin Auto Repair & Towing ★★★★★

Toy Doctor ★★★★★

Today`s Automotive ★★★★★

The Jag Shop ★★★★★

T V G Inc ★★★★★

T & T Tire ★★★★★

Auto blog

Crash victim found still inside car 6 hours after it was towed away [w/video]

Wed, Jan 7 2015Police near Dayton, OH, have quite a confusing case on their hands after the victim of a crash early on New Year's Day couldn't initially be found. Six hours later, the man was discovered lying on the vehicle's floorboard at the tow yard. The unidentified person was admitted to a local hospital in critical condition with possible leg injuries. The police first responded to the scene of the crash around 3:00 am on New Year's Day when a Chevrolet Impala hit a utility pole and drove through a fence, according to WHIO News. The authorities claim that they searched for the man for an hour and a half and came up with nothing. The car was then hauled away to the yard, which was only about 500 feet away. The tow yard worker found the man around 9:00 am and called 911. However, he was clearly dubious about the injured man's predicament and suggested to the operator that he might have returned to the Impala. Police are still investigating the incident. According to WHIO, authorities might have somehow missed the man in the sedan during the search. Alternatively, he could have left the scene of the accident and later returned. Watch the video below for more about this bizarre case. The video meant to be presented here is no longer available. Sorry for the inconvenience. News Source: WHIO via Yahoo Autos Chevrolet Police/Emergency Videos Sedan

Chevrolet Bolt EV Concept foreshadows an affordable, 200-mile EV future [w/videos]

Mon, Jan 12 2015Confirming numerous reports and rumors, Chevrolet introduced the Bolt EV Concept, "a vision" of a 200-mile EV with an entry price of around $30,000. Those lofty promises ride atop a funky crossover that made its global debut at the 2015 Detroit Auto Show. The orange five door features a spacious greenhouse, complemented by a glass roof and thin D-pillar. A narrow grille and slim LED headlights crown a high fascia that leaves little ahead of its front axle. It's a similar story in back, as General Motors' design boss Ed Welburn sought to limit overhangs and maintain the Bolt's small footprint. "Form and function have never meshed so well together," Welburn said. "No compromises were made when it came to aesthetics and the elements that contribute to the Bolt EV concept's range, resulting in a unique proportion that's sleek, efficient and obviously a Chevrolet." The cabin is not unlike current Chevrolet compacts, with the MyLink touchscreen and a detached instrument cluster dominating the sparse dash. Unlike cars like the Sonic, which features a similar design for its instrument cluster, A Volt-like display is found over the steering column. "The Bolt EV concept is a game-changing electric vehicle designed for attainability, not exclusivity," CEO Mary Barra said. "Chevrolet believes electrification is a pillar of future transportation and needs to be affordable for a wider segment of customers." Take a look at both the official gallery of Bolt images, as well as our live shots. And then scroll on down for more comments from GM brass, in the official press release. Chevrolet Bolt EV Concept Signals Brand's EV Strategy Affordable, long-range concept builds on brand's electrification leadership 2015-01-12 DETROIT – Chevrolet today made a significant statement on its commitment to electrification with the introduction of the Bolt EV concept – a vision for an affordable, long-range all-electric vehicle designed to offer more than 200 miles of range starting around $30,000. "The Bolt EV concept is a game-changing electric vehicle designed for attainability, not exclusivity," said General Motors CEO Mary Barra. "Chevrolet believes electrification is a pillar of future transportation and needs to be affordable for a wider segment of customers." Leveraging the electrification prowess established by Volt and Spark EV, the Bolt EV concept is designed to offer long-range performance in all 50 states and many global markets.

Recharge Wrap-up: Lexus CT 200h is NWAPA's favorite hybrid, 'No Charge to Charge' in LA

Thu, Jul 24 2014The Northwest Automotive Press Association (NWAPA) has given the Lexus CT 200h its Favorite Hybrid title. It named the compact luxury hybrid its favorite of 2014 at its Drive Revolution in Portland (where it also named the new Volkswagen Golf TDI the Northwest Green Car of the Year). According to NWAPA president Nik Miles, the CT 200h earned the honor for "impressive combination of state-of-the-art small car luxury and hybrid technology." For 2014, the Lexus CT200h got an updated front end, including the spindle grille we've been seeing on new Lexus vehicles, plus a redesigned steering wheel and sliding sun visors. Read more in the press release below. Chevrolet credits the Malibu for helping make stop-start mainstream. Chevrolet started including stop-start technology standard in Malibus equipped with the four-cylinder engine. Chevy has sold about 83,000 of that model, so 97 percent of 2014 and 2015 Malibu sales include stop-start. Now, that technology has made its way into the 2015 Impala. With drivers idling an average of 16 minutes a day, stop-start can significantly reduce harmful emissions and save fuel. According to Navigant Research, we can expect annual sales of cars equipped with stop-start technology to surpass 55 million by 2022. Read more in the press release below. Nissan Leaf customers in Los Angeles will get access to free charging beginning August 15. Nissan is extending its "No Charge to Charge" promotion to LA, which will allow customers to charge at public charging stations at no cost. Leaf customers - including those who bought or leased their car from the participating dealerships on or after July 1 - will get an EZ-Charge card, allowing them to use ChargePoint, Blink, CarCharging, AeroVironment and NRG eVgo chargers for free. Rapid chargers can charge the Leaf's battery to 80 percent in 30 minutes. Nissan plans to offer the "No Charge to Charge" in at least 14 more markets in the US, bringing the total to 25, within the next year. See the press release below for more details. California will get six all-electric school buses for three school districts as part of a demonstration program. The California Energy Commission awarded a grant of $1.4 million for the program to National Strategies LLC; this is in addition to a $2.2-million grant from the South Coast Air Quality Management District. The EV buses use vehicle-to-grid technology, allowing them to sell energy back to the grid when it is needed.