Custom Made 2013 Camaro Zl1 With One Of A Kind Wide Body Kit And Lambo Doors on 2040-cars

Dubai, Dubai, United Arab Emirates

|

Limited edition Camaro ZL1 Custom made Camaro ZL1 with one of a kind wide body kit (1pc in the world). 580bhp 6.2l supercharged beast on the road with brand new Pirelli tires. Custom made 3pc wheels specially ordered from US(335/25/22back 265/30/22front) Oracle halo colorshift headlights Lambo style doors Carbon fiber front lip, side skirts, hood vents, front and back fenders, rear diffuser, rear spoiler and chevy logos Ambient lights added in the interior. Full options The car is in a perfect condition with no accidents and a real head turner. Contact no : +971563601090 / +971558455287 |

Chevrolet Camaro for Sale

2002 chevrolet camaro z28 ss convertible 2-door 5.7l

2002 chevrolet camaro z28 ss convertible 2-door 5.7l 10 heated leather sunroof traction control tint parking sensors keyless entry

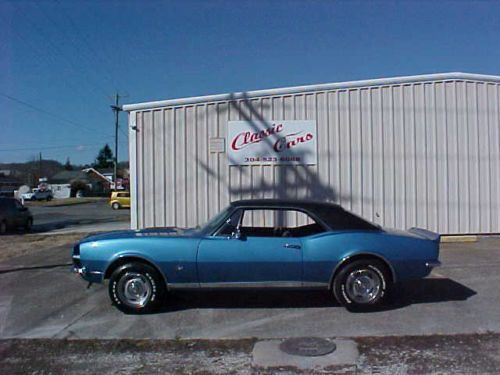

10 heated leather sunroof traction control tint parking sensors keyless entry 1967 chevrolet camaro base hardtop 2-door 5.3l(US $28,000.00)

1967 chevrolet camaro base hardtop 2-door 5.3l(US $28,000.00) 2000 chevrolet camaro z28 ss convertible 2-door 5.7l

2000 chevrolet camaro z28 ss convertible 2-door 5.7l 1977 chevrolet "q code" z28 - sport coupe camaro - awesome fast car(US $10,900.00)

1977 chevrolet "q code" z28 - sport coupe camaro - awesome fast car(US $10,900.00) 1967 camaro r s / ss(US $34,500.00)

1967 camaro r s / ss(US $34,500.00)

Auto blog

GM recalling 118K Colorado, Canyon pickups over missing hood latches

Thu, 20 Dec 2012General Motors has announced a recall of 118,800 Chevrolet Colorado and GMC Canyon pickup trucks due to the possibility of secondary hood latches not being installed at the time of manufacture. The affected vehicles are from the 2010, 2011 and 2012 model years, all of which were built between November 9, 2009 and August 28, 2012.

According to the official National Highway Traffic Safety Administration report, these trucks fail to "comply with the requirements of Federal Motor Vehicle Safety Standard No. 113, 'Hood Latch System.' The hood may be missing the secondary hood latch." In other words, owners of these trucks could find their vehicles' hoods opening unexpectedly while driving.

The official recall campaign is expected to begin on January 17, 2013. Dealers will inspect the affected pickups and if a secondary hood latch is not present, one will be installed free of charge. Scroll down to read the official NHTSA report.

GM's MPG overstatement could affect 2 million vehicles

Tue, May 17 2016Late last week, GM admitted that three of its large SUVs fuel economy window stickers did not match their actual efficiency ratings, and so the vehicles couldn't be sold. The stickers on the 2016 Chevy Traverse, GMC Acadia, and Buick Enclave said their ratings were one to two miles per gallon better than they should have been. Officially, the number of affected vehicles sits at about 60,000. But Consumer Reports makes a good point: what's up with all of the previous model year SUVs that are basically the same vehicle? To wit: the 2016 model year vehicles are not substantially different than the 2015 or the 2014, or even going all the way back to 2007. On the EPA's fuel economy website, all of these older models will "have better stated fuel economy numbers than the new vehicles in GM's dealerships," Consumer Reports noted. CR's best point, and the one that makes the 60,000 number potentially grow to 2 million if all of the vehicles built on this platform are affected, is that "[i]t seems unlikely that the company would change the powertrain on these carryover models so late in their model cycles in a way that would cause a dramatic, negative impact on fuel economy." GM says that earlier model year SUVs are not affected and the EPA did not respond to CR's question about the potential for more discrepancies. We've seen automakers reverse course before, so if GM has to come out with a mea culpa soon, don't be surprised. GM is rushing corrected stickers to dealers so that the SUVs can be sold again, but a fix for the already-sold vehicles could be trickier to solve. Related Video: Related Gallery 2013 GMC Acadia View 16 Photos News Source: Consumer Reports Government/Legal Green Buick Chevrolet GMC Fuel Efficiency mpg gmc acadia chevy traverse

General Motors Recalls Nearly 780,000 Cars To Fix Deadly Problem

Thu, Feb 13 2014General Motors is recalling nearly 780,000 compact cars in North America because the engines can shut down unexpectedly and cause crashes. The company says six people have been killed in crashes related to the problem. The recall affects Chevrolet Cobalts and Pontiac G5s from the 2005 through 2007 model years. U.S. safety regulators say the weight of the key ring and rough roads can move the ignition switch out of the run position, cutting the engine and electricity. If that happens, air bags may not work. GM says there have been 22 crashes from the problem. All happened at high speeds. Dealers will replace the ignition switch for free. GM says owners should remove nonessential items from key rings until the problem is fixed. Related Gallery Chevy Impala Earns Highest Accolades From Consumer Reports Recalls Chevrolet GM Pontiac Cobalt