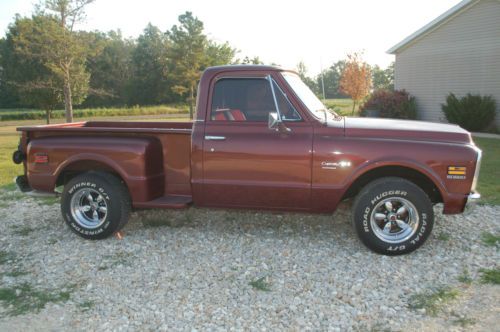

1972 Chevy Stepside Truck~sharp on 2040-cars

Bethel, Missouri, United States

|

1972 Chevy Stepside c-10 truck that has been restored. Runs great! Since we have owned it, it has been used in parades and a local car show, in which it won first place.

Truck has 88, 758 miles on it. Motor and transmission has 8800 miles on them. It has a 327 motor, 8 cylinder. A little cold natured, but once started runs perfect! No rust Has air conditioning Power steering Needs: Truck needs a new mirror, which we have and it will come with truck. We just haven't put it on. Needs a new gas cap, which we also have, and it will come with the truck. The bed of the truck has some peeling to the top layer. I think the sun must have hit it when it was outside. This is a sharp looking truck and runs great. Truck is for sale locally and we reserve the right to sell. Please ask if any questions We will take a paypal deposit to insure you want the truck. If paying with check, cashiers check or money order, truck will not be released until payment has cleared. Thanks |

Chevrolet C-10 for Sale

1968 c10 short bed(US $1,700.00)

1968 c10 short bed(US $1,700.00) 1967 chevrolet c10 2wd 6 cyl 3 spd. extra parts(US $700.00)

1967 chevrolet c10 2wd 6 cyl 3 spd. extra parts(US $700.00) 1971 chevy truck c10, shaved, jet black, aluminum 427ci sbc(US $25,000.00)

1971 chevy truck c10, shaved, jet black, aluminum 427ci sbc(US $25,000.00) 1966 chevrolet c30 (c10 c20) 1 ton truck with custom camper - only 37,000 miles

1966 chevrolet c30 (c10 c20) 1 ton truck with custom camper - only 37,000 miles 1968 gmc custom short box pickup truck hot rod lowered b&m blower

1968 gmc custom short box pickup truck hot rod lowered b&m blower 1971 chevrolet c-10 custom deluxe swb v8 manual cool truck!

1971 chevrolet c-10 custom deluxe swb v8 manual cool truck!

Auto Services in Missouri

Wrench Tech ★★★★★

Valvoline Instant Oil Change ★★★★★

Tint Crafters Central ★★★★★

Riteway Foreign Car Repair ★★★★★

Pevely Plaza Auto Parts Inc ★★★★★

Performance By Joe ★★★★★

Auto blog

Chevy Bolt 200-mile EV going into production near Detroit

Thu, Feb 12 2015Where there's smoke, there's fire, apparently. The rumors of the Chevy Bolt going into production have been proven correct, with an announcement this morning at the Chicago Auto Show that the 200-mile, all-electric Bolt will be built at the Orion Assembly facility near Detroit. GM didn't say exactly when the Bolt will be built, but GM North America president Alan Batey said in a statement that, "We are moving quickly because of its potential to completely shake up the status quo for electric vehicles." He's not kidding. GM is talking about a $30,000 price tag for an EV that can do twice as many electric miles as any non-Tesla mass-production EV today. Previous hints have the Bolt starting production next year for a market debut in 2017, and with all of the accuracy we've seen from these secret releases up to now, we're going to say this is probably accurate until we hear otherwise. We still have questions about the price tag, but for now we'll try to track down more information here in Chicago. Chevrolet Commits to Bolt EV Production Game-changing, long-range EV to be built at Orion Assembly facility in Michigan CHICAGO – Chevrolet this morning confirmed production of its next-generation pure electric vehicle, based on the Bolt EV concept. It will be built at General Motors' Orion Assembly facility near Detroit. GM North America President Alan Batey made the announcement ahead of the Chicago Auto Show. The Bolt EV concept was introduced last month at the North American International Auto Show in Detroit. "The message from consumers about the Bolt EV concept was clear and unequivocal: Build it," said Batey. "We are moving quickly because of its potential to completely shake up the status quo for electric vehicles." Leveraging the industry-leading battery technology found in the Chevrolet Volt and Spark EV, the Bolt EV concept was developed as a game-changing, long-range pure electric for all 50 states, designed to offer more than a GM-estimated 200 miles of range at a target price of around $30,000. The progressively styled concept vehicle features selectable driving modes for preferred driving styles, such as daily commuting, and it was designed to support DC fast charging. "We're proud that Chevrolet has decided to produce the Bolt EV here in Michigan at the Orion Assembly facility," Gov. Rick Snyder said. "Michigan unquestionably remains the global automotive leader.

GM patent reveals new two-stage turbocharger

Fri, Jun 24 2016Modern turbochargers may be some of the best ever made, but performance is something that engineers are always trying to improve. According to GM Inside News, General Motors (GM) is hoping to alleviate some of the negative aspects of a two-stage turbocharger setup with a newly-patented design. The patent, that was filed on May 19, 2016, reveals a clever bypass system that allows the engine, a four-cylinder unit, to optimize both the low-pressure and high-pressure inlets for its respective functions. According to the filing, a conventional two-stage turbocharger setup is engineered to allow both turbines to operate simultaneously at low and mid engine speeds. At high engine speeds, only the low-pressure turbine works. The setup can't isolate either the low or high pressure side, which can impair low-end performance. GM's new two-stage turbocharger setup looks to eliminate this by linking the high-pressure turbo to the exhaust manifold through the high-pressure inlet duct. The low-pressure turbo is attached to the high-pressure turbo by a low-pressure inlet duct, which is linked to a connecting channel. A single actuator that is housed in the exhaust manifold creates a bypass that can opens the high-pressure inlet or close the connecting channel. Depending on what the engine load and speed is, the ECU guides the actuator—a single rotating spindle with discs corresponding to flanges on the high and low pressure sides—to isolate one of the two turbos. Isolating the turbos allow the respective inlets to be engineered for the best possible fluid dynamic performance. The setup should increase performance and decrease lag. There's no word on what car this setup will make an appearance on, but it will most likely be used in premium vehicles before trickling down to the rest of GM's vehicles. Related Video: News Source: GM Inside News, AutoGuide via GM Authority Cadillac Chevrolet GM Technology Sedan turbo patent engine turbocharging

Chevy's 6.6-liter Duramax is pretty much all new

Thu, Sep 29 2016To say there's a heated battle in heavy-duty pickups is an understatement, with Chevrolet, Ford, and Ram constantly trading blows of increased torque, horsepower, and towing capacity. The latest salvo is the revised, more powerful turbo diesel 6.6-liter Duramax V8 in the 2017 Chevy Silverado. It has 910 pound-feet of torque, an increase of 145, putting it nearly level with the Ford Super Duty. Here's a closer look at where those gains come from. How exactly did Chevrolet add all that torque plus 48 horsepower? The automaker essentially took a fine-tooth comb to the entire engine. Chevy says it changed 90 percent of the V8, and the cumulative effect of those small changes adds up to big increases. As you might guess, the turbocharger is updated. The larger unit features electric actuation of the variable nozzle turbine (VNT), and what Chevy calls a double axle cartridge mechanism that separates the VNT moving parts from the housing. That helps with heat performance as well, with a claim that the exhaust side of the turbo can run continuously up to 1,436 degrees Fahrenheit. Helping that cause are six exhaust gaskets made of Inconel - an nickel alloy that contains chromium and iron – and upgraded stainless steel for the exhaust manifold. Despite having the same cast iron cylinder block, albeit with some minor enhancements, the engine has new cylinder heads, pistons, piston pins, connecting rods, and crankshaft, which have all been upgraded to handle 20 percent higher cylinder pressures. Alongside the increase in pressure, Chevrolet also increased the cylinder head's structure with a honeycomb design. The pattern features high-strength aluminum with dual layer water jackets that not only improve strength, but also optimize water flow for better cooling. For 2017, the cylinder head also benefits from integrated plenum that aids the engine in getting more air under heavy loads. The cylinder head isn't the only component to get a minor update, as the pistons have a larger diameter pin for improved oil flow. The same detailed improvements has been bestowed to the humble connecting rods (second in our hearts only to the inanimate carbon rod). The new design has the bolts oriented roughly 45-degrees to the rod instead of parallel. The angle split design, as it's called allows for easier passage through the cylinder.