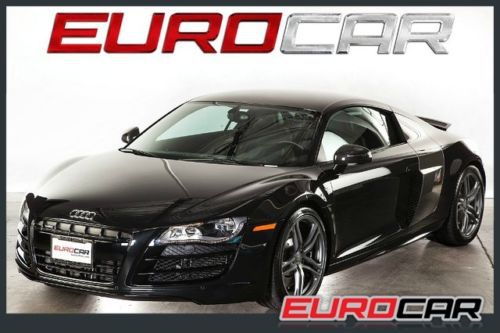

Audi R8 5.2l Titanium Package Enhanced Leather Package, $175,050.00 Msrp on 2040-cars

Costa Mesa, California, United States

Body Type:Coupe

Vehicle Title:Clear

Engine:10

Fuel Type:Gas

For Sale By:Dealer

Used

Year: 2012

Make: Audi

Model: R8

Mileage: 4,751

Sub Model: 5.2L

Disability Equipped: No

Exterior Color: Black

Doors: 2

Interior Color: Black

Drivetrain: All Wheel Drive

Audi R8 for Sale

Audi r8 spider, custom suspension, custom exhaust, one of a kind(US $138,888.00)

Audi r8 spider, custom suspension, custom exhaust, one of a kind(US $138,888.00) 11 audi r8 quattro spyder awd 5.2l 18k navigation sensors rear cam(US $124,995.00)

11 audi r8 quattro spyder awd 5.2l 18k navigation sensors rear cam(US $124,995.00) 2011 audi r8 spyder convertible daytona grey/carbon pkg/5k miles!(US $126,995.00)

2011 audi r8 spyder convertible daytona grey/carbon pkg/5k miles!(US $126,995.00) One owner low miles factory warranty carbon fiber accents new tires(US $112,888.00)

One owner low miles factory warranty carbon fiber accents new tires(US $112,888.00) 2009 audi r8 base coupe 2-door 4.2l low miles!!

2009 audi r8 base coupe 2-door 4.2l low miles!! 2015 audi r8 4.2 v8 awd quattro 430+ hp 6 speed manual(US $144,335.00)

2015 audi r8 4.2 v8 awd quattro 430+ hp 6 speed manual(US $144,335.00)

Auto Services in California

Z Best Auto Sales ★★★★★

Woodland Hills Imports ★★★★★

Woodcrest Auto Service ★★★★★

Western Tire Co ★★★★★

Western Muffler ★★★★★

Western Motors ★★★★★

Auto blog

Ford GT dominates Le Mans qualifying, gets slapped with performance adjustment

Fri, Jun 17 2016Fifty years after Bruce McLaren and Chris Amon drove the Ford GT40 to victory at the 24 Hours of Le Mans, Ford is poised for a historic return to the Circuit de la Sarthe. The new Ford GT took the top two qualifying positions in the LMGTE Pro class, and four of the top five. Ferrari's 488 filled in the rest of the spots in the top seven, the first two from AF Corse. In other words, we're primed for a reboot of the classic Ford-Ferrari feud at this year's race. Or not, as the ACO, which organizes the 24 Hours of Le Mans, announced sweeping pre-race Balance of Performance (BOP) adjustments this morning that make this year's GT class anybody's race. In LMP1, last year's overall winner Porsche locked up the top two spots with the 919 Hybrid and will lead the entire field at race start. Toyota's two-car factory effort followed with qualifying times 1.004 and 2.170 seconds behind the pole lap. Audi rounds out the manufacturer-backed LMP1 class in fifth and sixth. Full qualifying results can be found here. The storyline for the GT cars is perfect - some say too perfect. Ford's class-leading times came after BOP adjustment to the Corvette Racing C7.R before qualifying. BOP is intended to level the playing field in the class by adjusting power, ballast, and fuel capacity. (Check out this explainer video for more, or even just if you love French accents.) But the process is riddled with unknowns and ripe for accusations of sandbagging. That is, if the Ford cars were intentionally slow in practice they could hope for BOP adjustment to improve their race chances. On the Corvette side, last year's GTE Pro winner went from the top of the field to the bottom, barely improving from practice to qualifying. If you think Le Mans is as rigged at the NBA Playoffs, well, it's not that simple. Because if Ford and Ferrari held back until qualifying - the eighth-place Porsche 911 RSR is three-and-a-half seconds off the class pole time - it was a pretty dumb strategy. This morning, the ACO tried to put things back in order by limiting the boost in the Ford GT's twin-turbo V6 and adding 11 pounds of ballast. Ferrari was also given extra weight but allowed more fuel capacity. The Corvette and Aston Martin teams were both given breaks on their air restrictors, which will allow their engines to make more power. Both Ford and Porsche also received extra fuel capacity.

2014 Audi S1 Quattro [w/video]

Fri, 21 Mar 2014Audi may only now be fully committing to the US compact car market with a range of A3 models, but it's got far more small car expertise than most Americans realize, and its offerings get even tinier, too. Back in 2010, Audi leapt into the subcompact premium fray - in all markets but the United States, Canada and China - with its A1. The A1 family has sold all right, but not quite as well as was expected, likely due to its price when optioned up. (It also doesn't help that the Volkswagen Polo is a great car on the same architecture and costs much less.)

But Audi seems compelled to make high-buck S trims of everything nowadays, so right on schedule, I've scored seat time in its new S1 Quattro. Under its gumdrop-colored hood is the very popular 2.0-liter TFSI motor. In this trim, it's good for 228 horsepower and 273 pound-feet of torque between 1,600 and 3,000 rpm. That's quite a lot of gumption for this little blaster - enough power for 0-60 in just 5.7 seconds.

My drive was originally supposed happen on a sub-zero frozen lake in Sweden, only Audi forgot to call Mother Nature and ask her to hold off on springtime. It would have turned into a slush drive and then a submarine test had I been told to stick to the original plan, so it was dusty, soggy and gravel-y pavement instead, which turned out to be a better real-world test anyhow. Plus, the car got even cuter when it was filthy.

Audi A3 outselling Mercedes CLA 2 to 1 in its first 3 months on sale

Thu, 10 Jul 2014The Audi A3 is on fire in US showrooms. Not literally of course, that would be horrible, and the situation we're referring to is a good thing indeed, as the Four Rings has a serious hit on its hands with the compact luxury sedan. Looking at just its first three months on the market, the entry-level model is outselling the Mercedes-Benz CLA-Class by nearly two to one.

The CLA was one of the hottest new cars of last year. Mercedes even called it the company's best launch in 20 years, but it sees as if that early sales performance has not been sustainable. According to Bloomberg, the CLA has seen its sales drop year-over-year in seven of the last eight months, and the new A3 came at just the right time to fill that void.

In June, Mercedes shifted 1,658 CLAs in the US, compared to 2,452 for the A3. The Merc has sold more units so far this year but only because the Audi sedan has only been on sale for three full months. With the two cars being relatively comparable as compact, front-wheel-drive, German luxury sedans, it appears buyers prefer the Four Rings over the Mercedes star, so far at least.

2040Cars.com © 2012-2025. All Rights Reserved.

Designated trademarks and brands are the property of their respective owners.

Use of this Web site constitutes acceptance of the 2040Cars User Agreement and Privacy Policy.

0.094 s, 7891 u